Closed circulating phase-change heat distribution system of industrial boiler

A closed cycle, industrial boiler technology, applied in heating systems, steam central heating systems, household heating, etc., can solve the problems that condensed water cannot be fully recovered, system heat energy waste, and steam trap failure, etc., to achieve simplified structure , improve thermal efficiency, avoid the effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

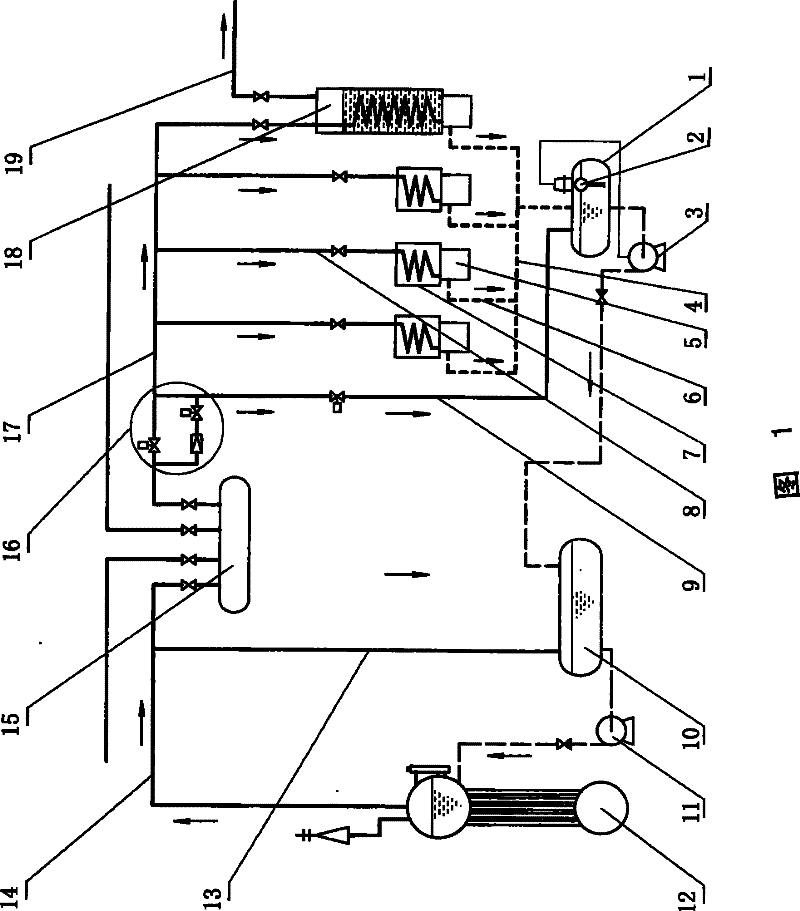

[0012] The content of the present invention will be further described below in conjunction with the accompanying drawings, but the actual application form of the present invention is not limited to the illustrated embodiment.

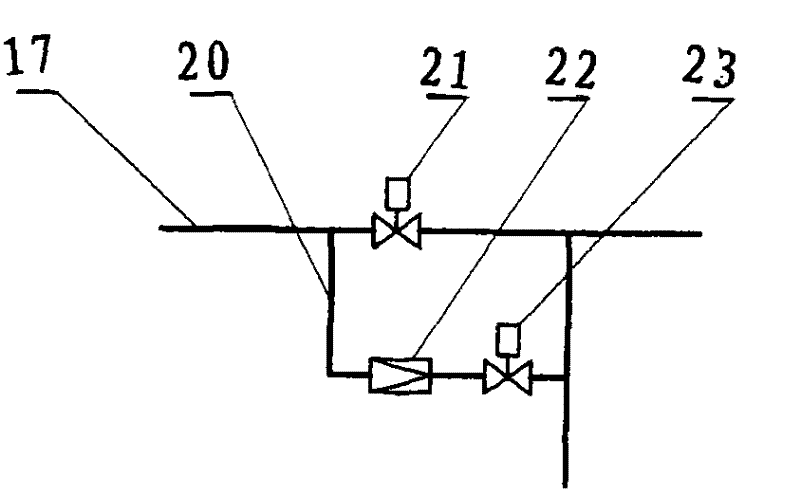

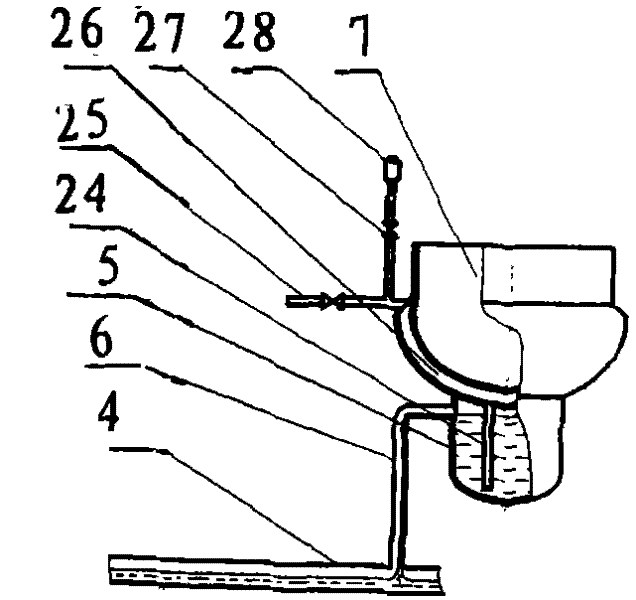

[0013] Referring to the accompanying drawings, the industrial boiler closed cycle phase change heating system of the present invention consists of a boiler 12, a water storage tank 10, a sub-cylinder 15, a high-temperature pump 3, 11, a heat-using device 7, a low-level liquid collection tank 1, and a secondary The steam boiler 18, the steam main pipe 14, the steam main pipe 17, the steam branch pipe 8 and the corresponding valves and connecting pipelines are composed. The boiler 12 is respectively connected to the water storage tank 10 and the sub-cylinder 15 through the steam main pipe 14, and the steam main pipe 17 connected with the steam outlet of the sub-cylinder 15 is provided with a standby pipeline 16, and the steam branch pipe 8 and Each is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com