Preparation method of novel all-weather cannon cleaning agent

An all-weather, cleaning agent technology, used in the preparation of new all-weather gun cleaning agents, can solve problems such as affecting cleaning operations, and achieve the effect of wide temperature range, good effect and strong cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of a novel all-weather gun cleaning agent, the preparation method is:

[0026] Add 40g of surfactant and 50g of inorganic base into the mixing tank, control the temperature at 20°C, stir for 10 minutes, then add 30g of organic solvent and 20g of additives, control the temperature to 35°C, stir for 20 minutes, and then add 780g of water and 2g of graphite Olefin-modified ferric oleate / boric acid polymer, continue to stir and mix for 1 hour, and after cooling to room temperature, the novel all-weather cleaning agent for guns can be obtained.

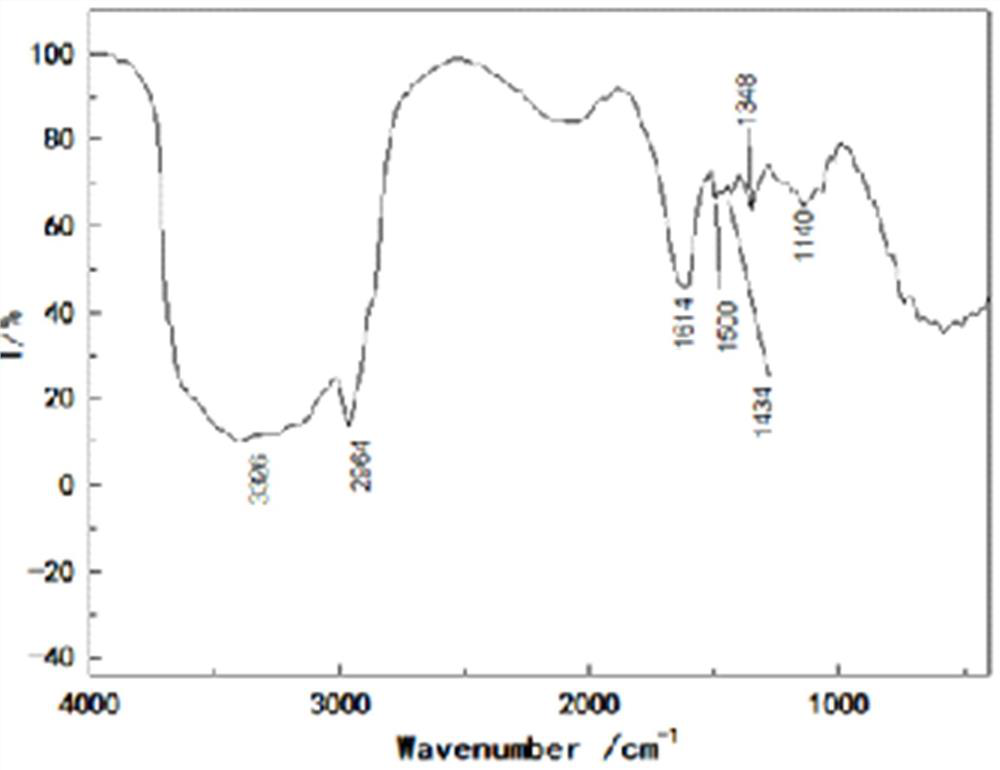

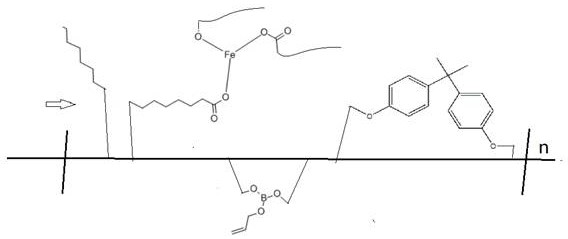

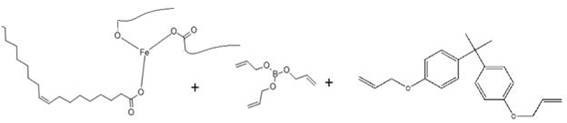

[0027] A kind of graphene modified ferric oleate / boric acid polymer, its preparation method is as follows:

[0028] Mix 17g of iron oleate, 4g of triallyl borate, 0.3-g of diallyl bisphenol A and 0.1g of emulsifier, under nitrogen protection, add 150g of petroleum ether, stir and disperse for 10min; then control the temperature to 65°C, then slowly add 10 g of benzoyl peroxide petroleum ether solution with a ma...

Embodiment 2

[0035] A preparation method of a novel all-weather gun cleaning agent, the preparation method is:

[0036] Add 50g of surfactant and 60g of inorganic base into the mixing tank, control the temperature at 35°C, stir for 20min, then add 40g of organic solvent and 30g of additives, control the temperature to 45°C, stir for 30min, and then add 820g of water and 3.4g Graphene-modified ferric oleate / boric acid polymer, continue to stir and mix for 3 hours, and after cooling to room temperature, the novel all-weather cleaning agent for guns can be obtained.

[0037] A kind of graphene modified ferric oleate / boric acid polymer, its preparation method is as follows:

[0038] Mix 19g of iron oleate, 7g of triallyl borate, 0.5g of diallyl bisphenol A and 0.3g of emulsifier, under nitrogen protection, add 160g of petroleum ether, stir and disperse for 17min; then control the temperature to 72°C, then slowly add 14g of benzoyl peroxide petroleum ether solution with a mass percentage conte...

Embodiment 3

[0044] A preparation method of a novel all-weather gun cleaning agent, the preparation method is:

[0045] Add 60g of surfactant and 70g of inorganic base into the mixing kettle, control the temperature at 45°C, stir for 30min, then add 50g of organic solvent and 40g of additives, control the temperature to 55°C, stir for 40min, then add 860g of water and 7g of graphite Olefin-modified ferric oleate / boric acid polymer, continue to stir and mix for 5 hours, and after cooling to room temperature, the novel all-weather cleaning agent for guns can be obtained.

[0046] A kind of graphene modified ferric oleate / boric acid polymer, its preparation method is as follows:

[0047] Mix 25g of iron oleate, 11g of triallyl borate, 0.8g of diallyl bisphenol A and 0.5g of emulsifier, under nitrogen protection, add 180g of petroleum ether, stir and disperse for 30min; then control the temperature to 80°C, then slowly add 20g of benzoyl peroxide petroleum ether solution with a mass percentag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com