Method for characterizing epoxy resin composite material interface mechanism

An epoxy resin and composite material technology, which is applied in the fields of analysis materials, electrical digital data processing, special data processing applications, etc., can solve the problems of high experimental cost, unstable experimental results, and high technical requirements, and the method is simple and easy to implement. , The experimental effect is stable and reliable, and the effect of reducing the experimental time and cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

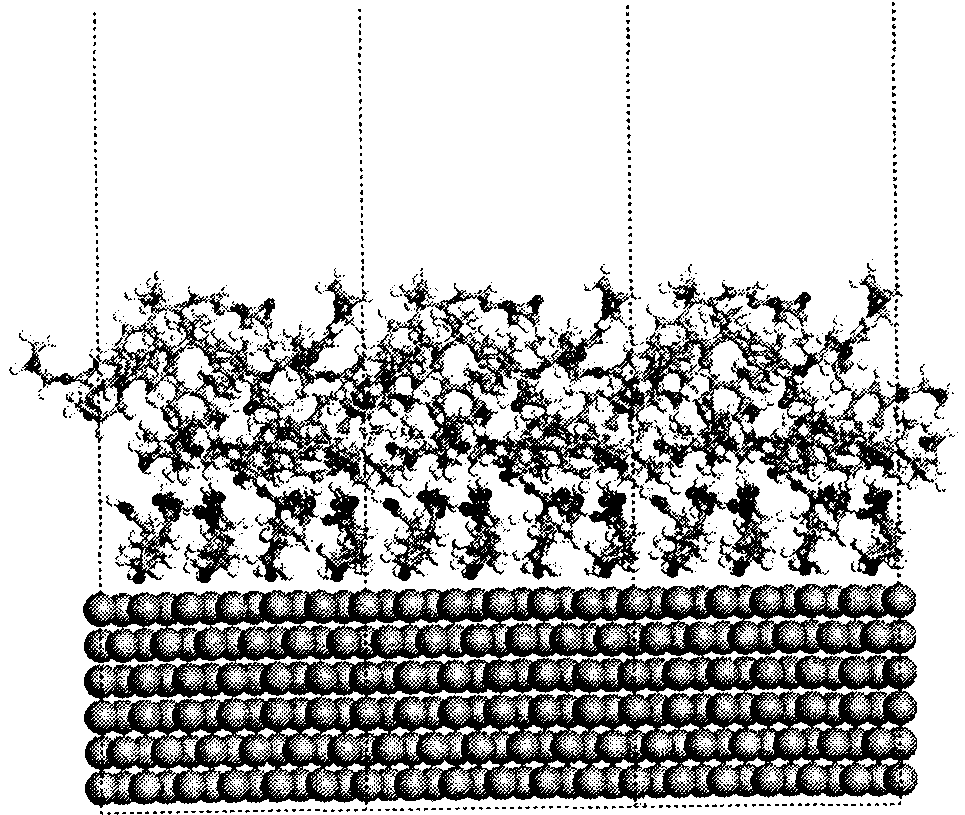

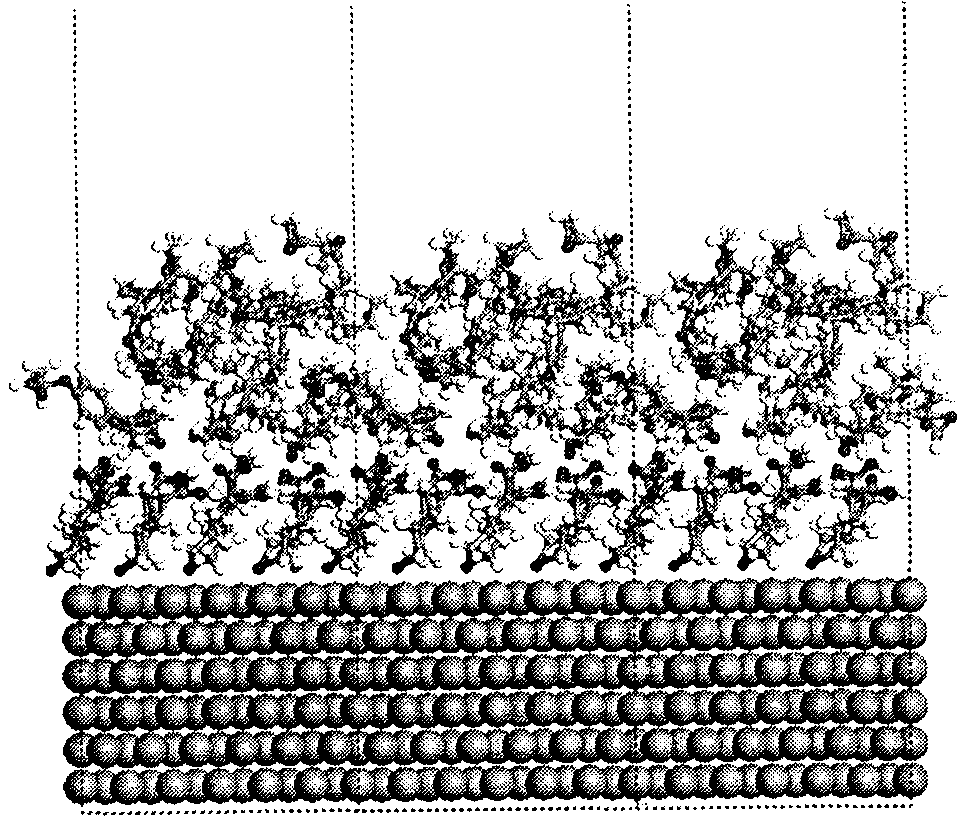

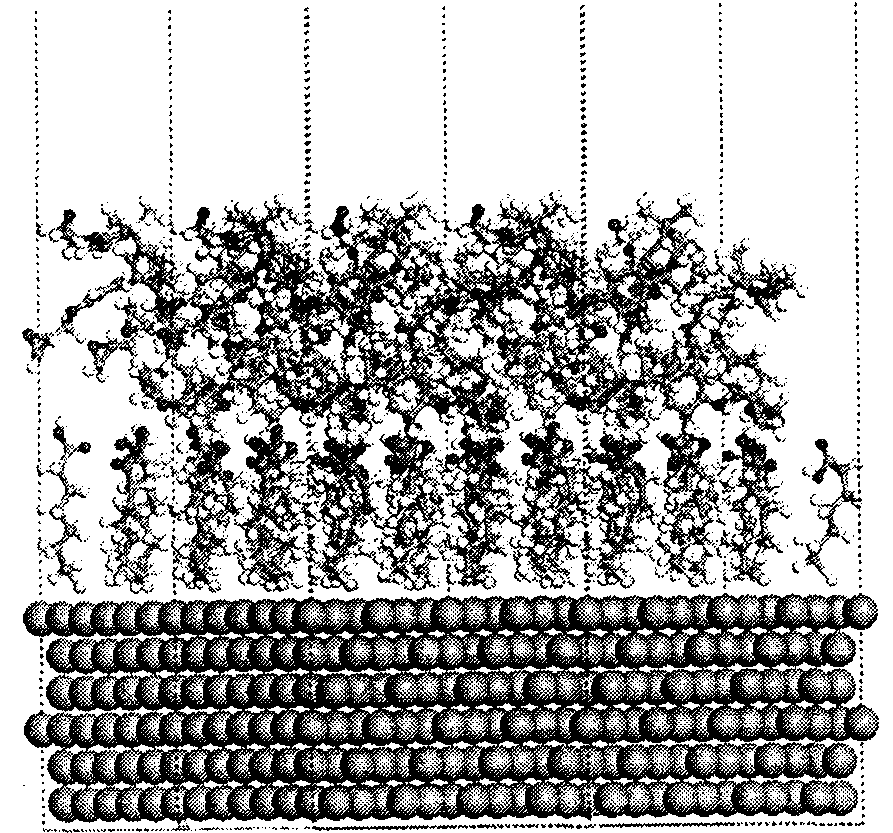

[0012] Specific Embodiment 1: The method for characterizing the interface mechanism of epoxy resin composite materials in this embodiment is implemented according to the following steps: 1. Establish an Au(111) surface model, and then calculate the concentration of thiol molecules on Au according to density functional theory and molecular dynamics methods. Surface self-assembled adsorption structure, and determine the structural parameters, and simulate the self-assembled modeled system; 2. Add an epoxy resin layer on the surface of the self-assembled modeled system to establish the interface structure between the modeled system and epoxy resin; 3. The molecular dynamics method was used to calculate the interface structure, and the influence of different functional groups and different chain lengths on the interface properties of epoxy resin composites was evaluated.

[0013] In this embodiment, the Au(111) surface structure unit such as figure 1 Shown, where A is 1×1, B is ...

specific Embodiment approach 2

[0014] Embodiment 2: The difference between this embodiment and Embodiment 1 is: in step 1, use the simulated Au(111) surface to adsorb the short-chain thiol molecular structure, establish a short-chain surface adsorption model, and then perform density functional theory Calculation, and based on the calculation results of the density functional theory of the short-chain surface adsorption model, the initial structure model of the long-chain thiol molecule adsorbed on the Au(111) surface was simulated and calculated, and the molecular dynamics calculation was performed to simulate the self-assembled model system. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0015] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the short-chain thiol molecules in the short-chain surface adsorption model are established in step one as methyl mercaptan and 2-mercaptoethanol; the adsorption structure with coverage Θ=1 use lattice unit to 2.03 As the initial adsorption height of the S atom, and using the default molecular bond length of the Cerius2 software as the initial bond length, the S-C bond length is 1.81 The C-H bond length is 1.14 C-C bond length is 1.54 C-O bond length is 1.51 O-H bond length is 1.11 The included angle θ of the S-C bond relative to the surface normal is 30°-60°. Other steps and parameters are the same as those in Embodiment 2.

[0016] In this embodiment, the included angle θ of the S-C bond relative to the surface normal is selected from multiple values between 30° and 60° for calculation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| unit cell dimension | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com