Endothermic reaction method

An endothermic reaction and reactor technology, applied in the field of chemical reaction, can solve the problems that it is difficult to ensure the heat transfer of reaction tubes, uneven temperature distribution in the axial and radial directions, and affect the reaction temperature, so as to save equipment investment, compact structure, Good heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

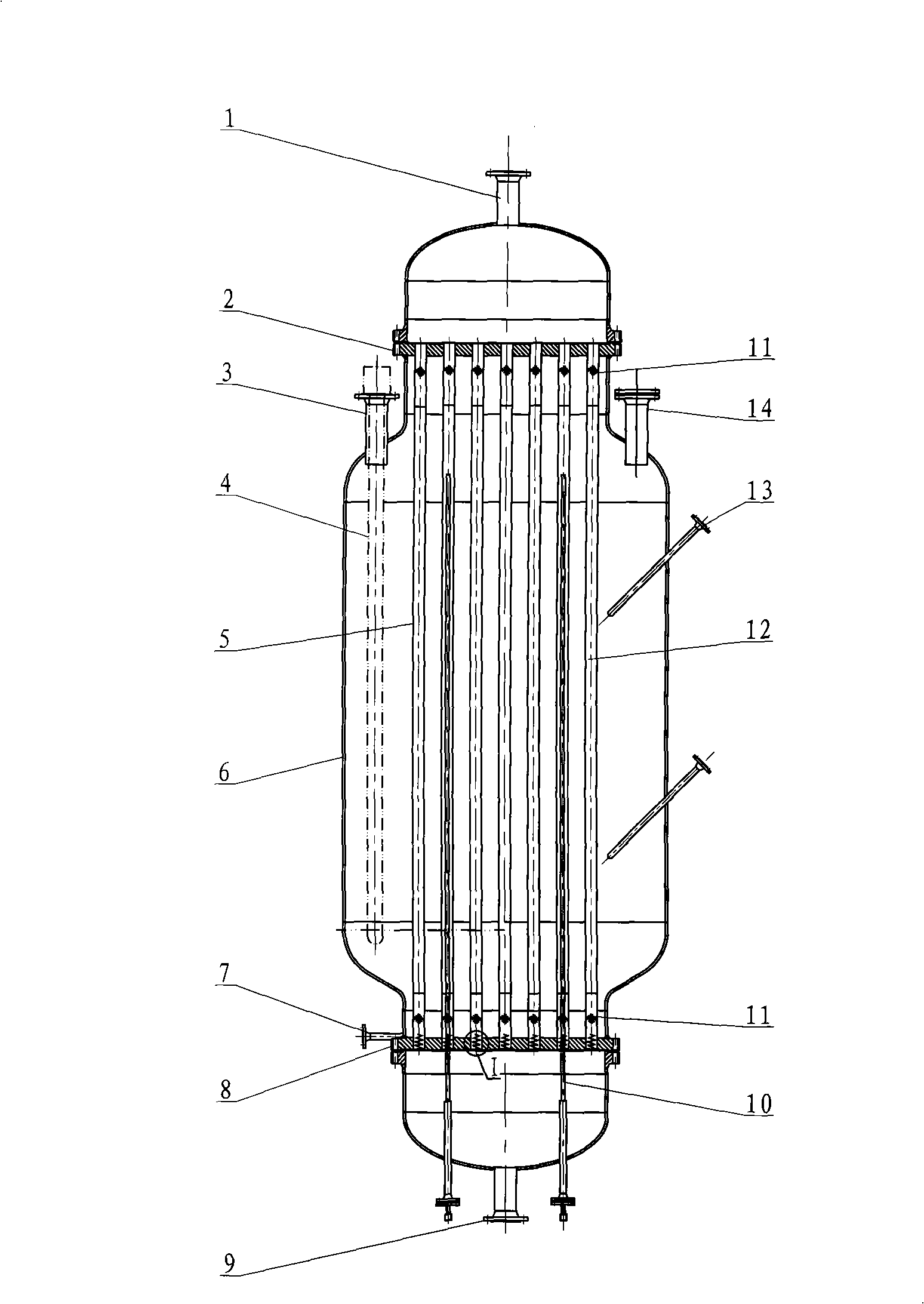

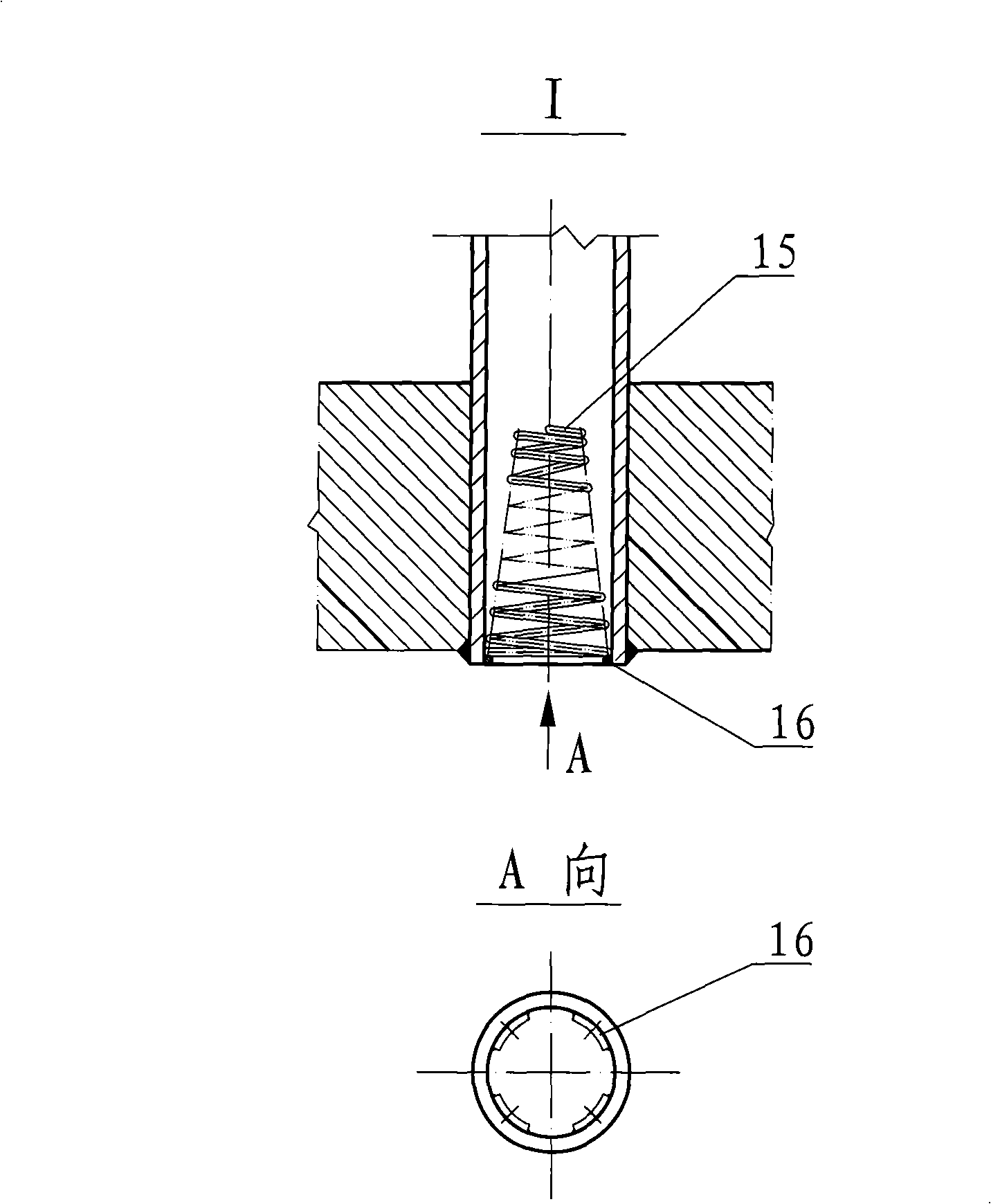

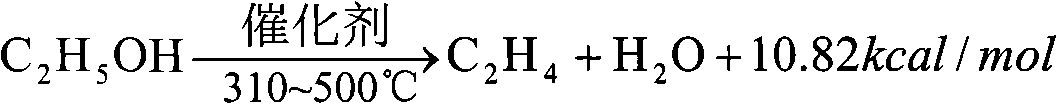

[0021] 6000 tons / year ethanol dehydration to ethylene plant, using ethanol as raw material, using figure 1 The shown tubular fixed-bed reactor adopts alumina catalyst. The shell side temperature is 450°C, the tube side temperature is 430°C, the reaction pressure is normal pressure, and the raw material space velocity is 1.0 hour -1. The diameter of the reactor cylinder is 1600 mm. The molten salt feeding port is located in the axial direction of the upper shell of the reactor. The outer diameter of the heating tube is 89 mm. Distribution, the outer diameter of the reaction tube is 57 mm, the outer diameter of the large end of the conical spring is 52 mm, and the number of shoulders in the tube wall at the lower end of the reaction tube is 4, and they are evenly distributed along the circumferential direction of the tube wall. 4 radial thermometers are evenly arranged along the circumferential direction at the inner diameter of the reactor of 900 mm, and 2 thermometers are re...

Embodiment 2

[0025] 3000 tons / year ethanol dehydration to ethylene plant, using ethanol as raw material, using figure 1 The shown tubular fixed-bed reactor adopts alumina catalyst. The shell side temperature is 430°C, the tube side is 410°C, the reaction is carried out under normal pressure, and the raw material space velocity is 0.8 hours -1 . The diameter of the reactor cylinder is 1000 mm. The molten salt feed port is located in the axial direction of the upper shell of the reactor. The outer diameter of the heating tube is 76 mm. The concentric circles are evenly distributed, the outer diameter of the reaction tube is 45 mm, the outer diameter of the large end of the conical spring is 40 mm, and the number of shoulders in the tube wall at the lower end of the reaction tube is 2, and they are evenly distributed along the circumferential direction of the tube wall. 4 radial thermometers are evenly arranged along the circumferential direction at the inner diameter of the reactor of 600 ...

Embodiment 3

[0027] 6000 tons / year urea low-pressure catalytic melamine plant, using urea as raw material, using figure 1 The tubular fixed-bed reactor shown uses silica-alumina gel catalyst. The shell side temperature is 375°C, the tube side is 355°C, the reaction pressure is normal pressure, and the raw material space velocity is 0.6 hours -1 . The diameter of the reactor cylinder is 1800 mm. The molten salt feed port is located in the axial direction of the upper shell of the reactor. The heating pipe is inserted into the shell from the axial direction of the upper part of the reactor, and is evenly distributed in concentric circles in the cylinder. Set up 4 radial thermometers at 300 mm, 600 mm, 900 mm, and 1000 mm in the inner diameter of the reactor, respectively, at 1 / 4, 1 / 2, and 3 / 4 heights of the reactor axial distance from the lower end of the reactor Set up 3 thermometers separately. The four radial temperatures measured were 375.5°C, 376.6°C, 376.1°C and 375.2°C; the three a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com