Preparation method of titanium dioxide photocatalyst of plant graded structure

A hierarchical structure, titanium dioxide technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low concentration and difficult industrialization, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

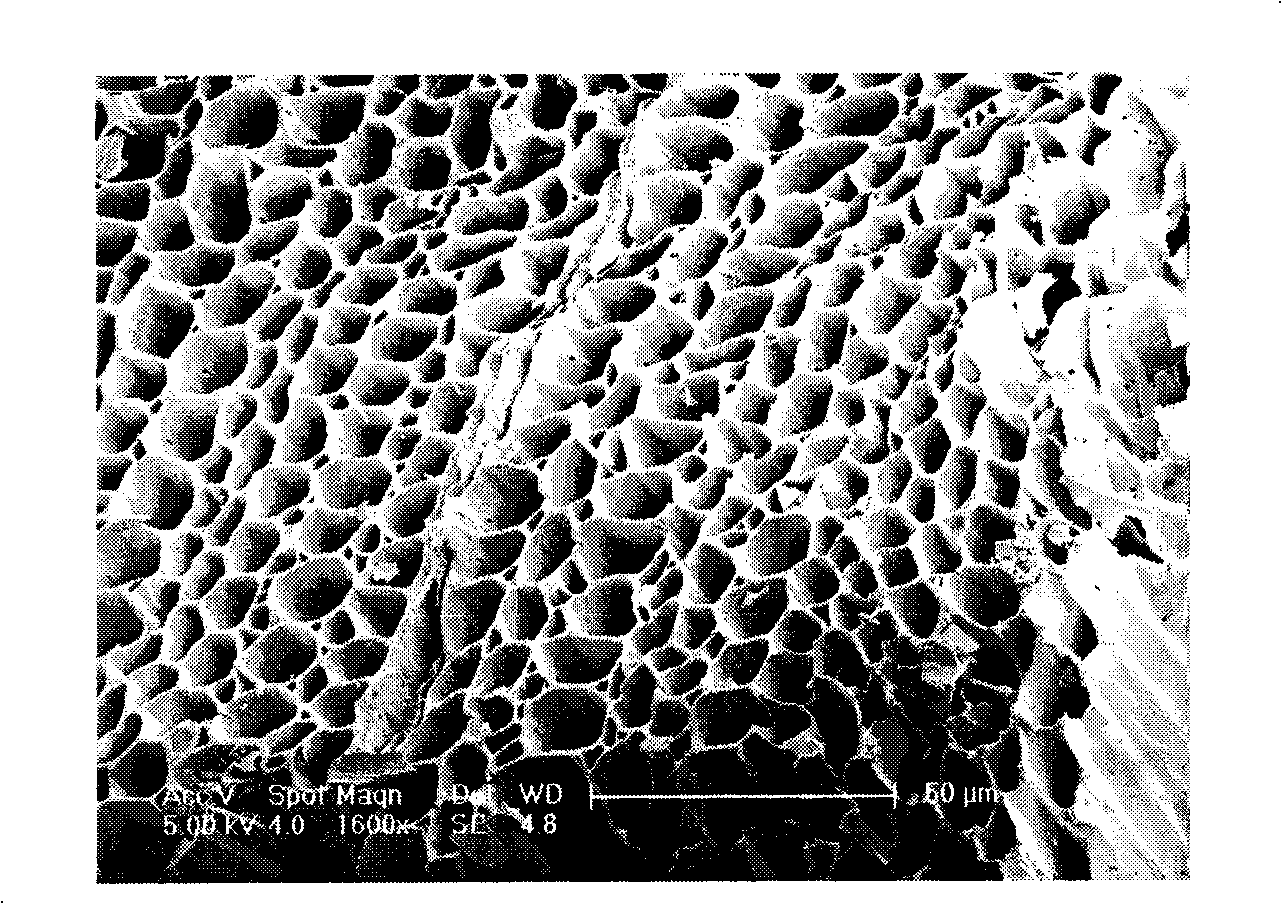

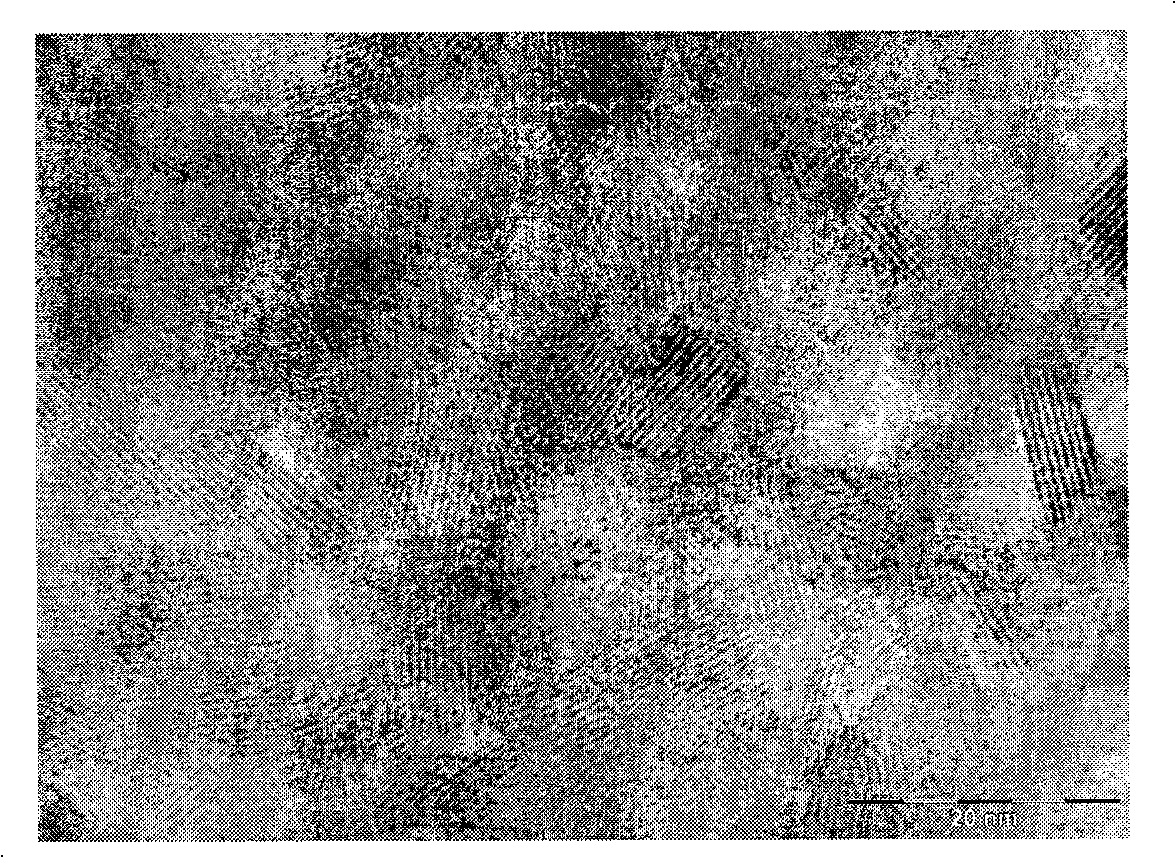

Image

Examples

Embodiment 1

[0026] In the first step, the Chinese fir wood block is put into 5wt% HCl solution for 3 hours to dissolve minerals that are not easy to be removed by sintering, then rinse with distilled water and dry. Then add 10wt% H 2 o 2 / NaOH solution at 60°C for 3 hours to dissolve most of the lignin. After taking out the wooden block, rinse it with distilled water and dry it for later use.

[0027] The second step is the preparation of the precursor solution. TiCl 4 Solution preparation scheme: under the condition of ice-water bath, water: concentrated hydrochloric acid: TiCl 4 Mix and stir at a volume ratio of 15:5:1 for 10 minutes to prepare a precursor solution with a concentration of 7.5% by weight.

[0028] In the third step, put the processed fir wood block into the prepared precursor solution for ultrasonic treatment, the ultrasonic power is 100W, and the ultrasonic time is 10 hours.

[0029] In the fourth step, after the ultrasonic wave is over, the sample is taken out, r...

Embodiment 2

[0033] In the first step, the Chinese fir wood block is put into 5wt% HCl solution for 3 hours to dissolve minerals that are not easy to be removed by sintering, then rinse with distilled water and dry. Then add 10wt% H 2 o 2 / NaOH solution at 60°C for 3 hours to dissolve most of the lignin. After taking out the wooden block, rinse it with distilled water and dry it for later use.

[0034] The second step is the preparation of the precursor solution. TiCl 4 Solution preparation scheme: under the condition of ice-water bath, water: concentrated hydrochloric acid: TiCl 4 Mix and stir at a volume ratio of 15:5:1.3 for 10 minutes to prepare a precursor solution with a concentration of 9.6% by weight.

[0035]In the third step, put the treated fir wood block into the prepared precursor solution for ultrasonic treatment, the ultrasonic power is 300W, and the ultrasonic time is 8 hours.

[0036] In the fourth step, after the ultrasonic wave is over, the sample is taken out, rin...

Embodiment 3

[0038] In the first step, the Chinese fir wood block is put into 5wt% HCl solution for 3 hours to dissolve minerals that are not easy to be removed by sintering, then rinse with distilled water and dry. Then add 10wt% H 2 o 2 / NaOH solution at 60°C for 3 hours to dissolve most of the lignin. After taking out the wooden block, rinse it with distilled water and dry it for later use.

[0039] The second step is the preparation of the precursor solution. TiCl 4 Solution preparation scheme: under the condition of ice-water bath, water: concentrated hydrochloric acid: TiCl 4 Mix and stir at a volume ratio of 15:5:2.04 for 10 minutes to prepare a precursor solution with a concentration of 14.3% by weight.

[0040] In the third step, put the treated fir wood block into the prepared precursor solution for ultrasonic treatment, the ultrasonic power is 400W, and the ultrasonic time is 5 hours.

[0041] In the fourth step, after the ultrasound is finished, the sample is taken out, r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com