Drying plant for high-moisture percentage plaster pasty materials

A high moisture content, paste-like technology, applied in dewatering/drying/concentrating sludge treatment, lighting and heating equipment, combustion methods, etc., can solve high energy consumption, secondary pollution, and no suitable drying methods and equipment have been explored and other problems to achieve the effect of increasing the calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

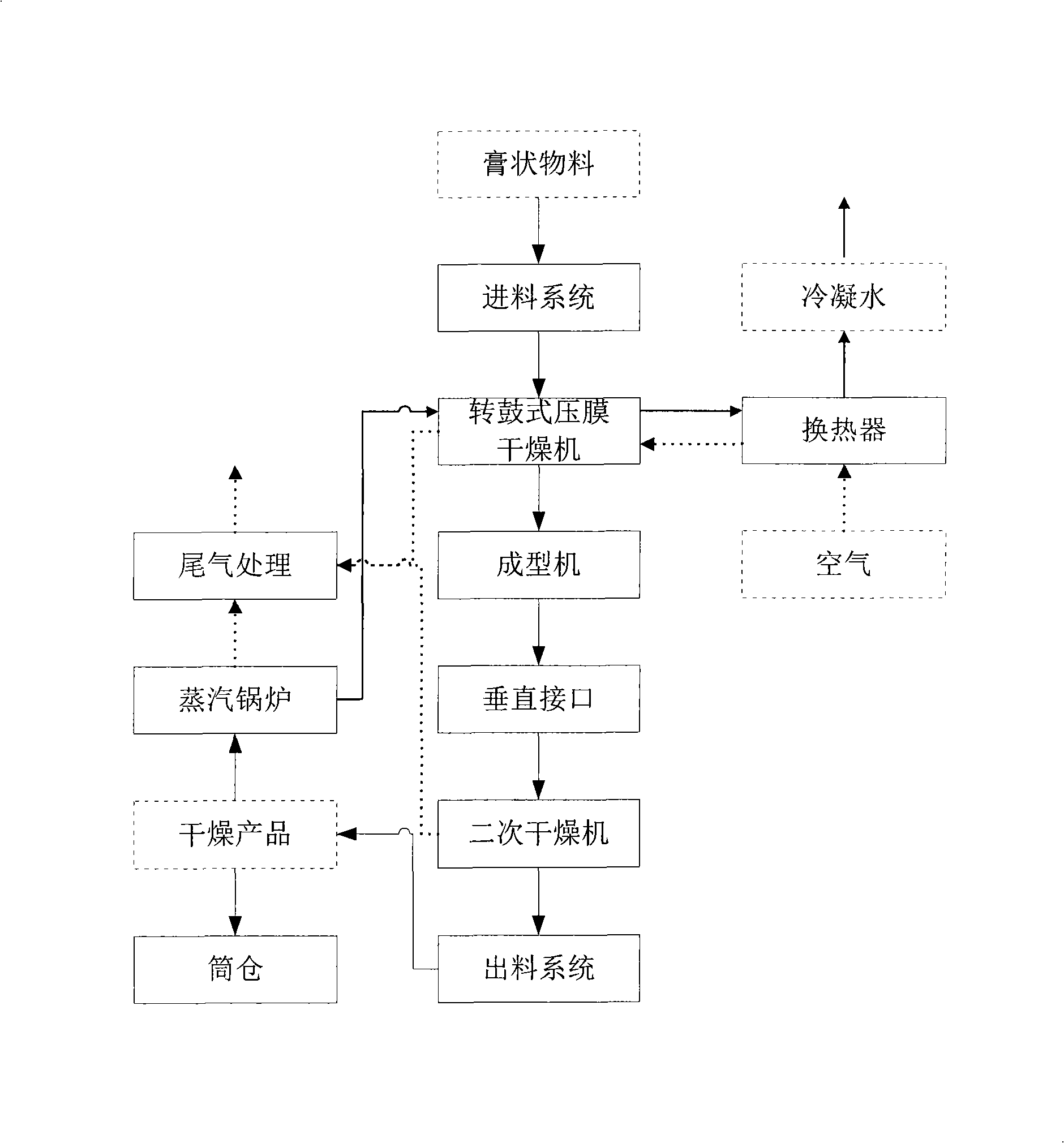

[0025] The pasty material is continuously and quantitatively input into the rotary drum type film sludge dryer by the feeding system. The rotary drum type film sludge dryer includes a rotating heating surface, a pressing roller, a conveying mesh belt and a suction hood. Saturated water vapor is fed into the rotating heating surface, and pressure rollers are installed on the outside. A conveyor mesh belt with good air permeability, wear resistance and high temperature resistance is installed between the pressure rollers. The rotating heating surface driven by the motor rotates slowly with the conveyor mesh belt. During the rotation process between the rotating heating surface and the conveying mesh belt, the material is dried through the heat conduction heating between the water vapor and the heating surface.

[0026] The material dried by the rotary drum pressure film sludge dryer is directly and continuously input into the molding machine for extrusion molding, and the molding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com