Microbe oil production method after polymer drive

A technology of microbial oil recovery and oil displacement, applied in the direction of microorganism-based methods, microorganisms, biochemical equipment and methods, etc., which can solve the problems of no research rules and methods that can be followed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, screening, cultivation and preservation of bacterial strains

[0032] Enrichment medium: K 2 HPO 4 0.1-0.5%, KH 2 PO 4 0.1-0.5%, NH 4 NO 3 0.1-0.2%, MgSO 4 ·7H 2 O0.01-0.1%, FeSO 4 0.001-0.01%, CaCl 2 0.001-0.01%, ZnSO 4 0.01-0.02%, CuSO 4 , 0.0005-0.001%, urea 0.01-0.1%, yeast extract powder 0.02-0.2%, crude oil 1-10%, polymer (molecular weight 14 million) 0.05-0.1%, the rest is water, pH 6.8-7.5, 121 ℃, Sterilize for 15-20min. Cultivate on a shaker at 45°C and 120rpm for 5-7 days.

[0033] Oil plate medium: K 2 HPO 4 0.1-0.5%, KH 2 PO 4 0.1-0.5%, NH 4 NO 3 0.1-0.2%, MgSO 4 ·7H 2 O0.01-0.1%, FeSO 4 0.001-0.01%, CaCl 2 0.001-0.01%, ZnSO 4 0.01-0.02%, CuSO 4 , 0.0005-0.001%, urea 0.01-0.1%, yeast extract powder 0.02-0.2%, crude oil 1-10%, polymer (molecular weight 14 million) 0.05-0.1%, agar 1.5-2%, the rest is water, pH6. 8-7.5, 121°C, sterilize for 15-20min.

[0034] Incline medium: peptone 1%, beef extract 0.3%, sodium ...

Embodiment 2

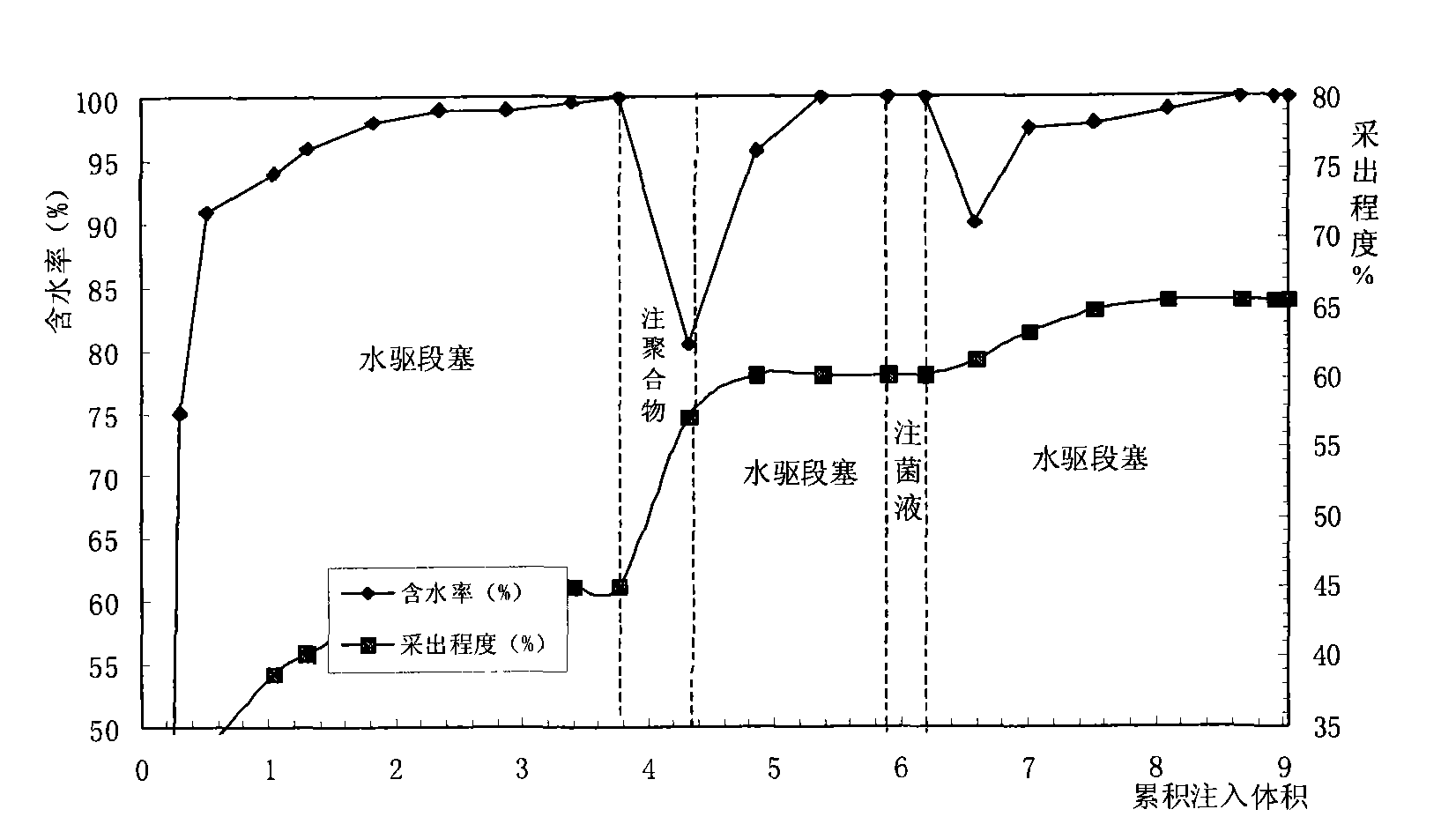

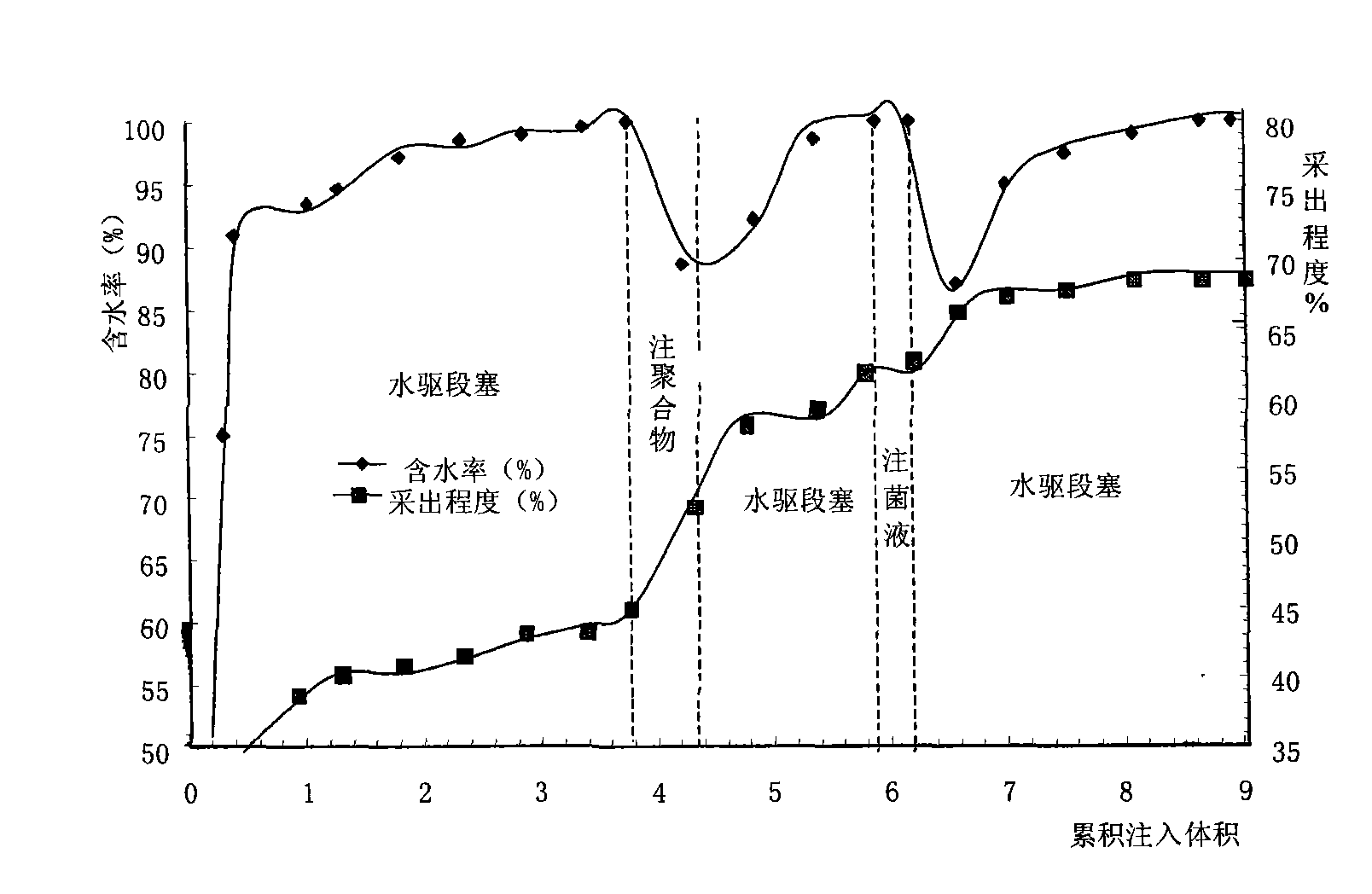

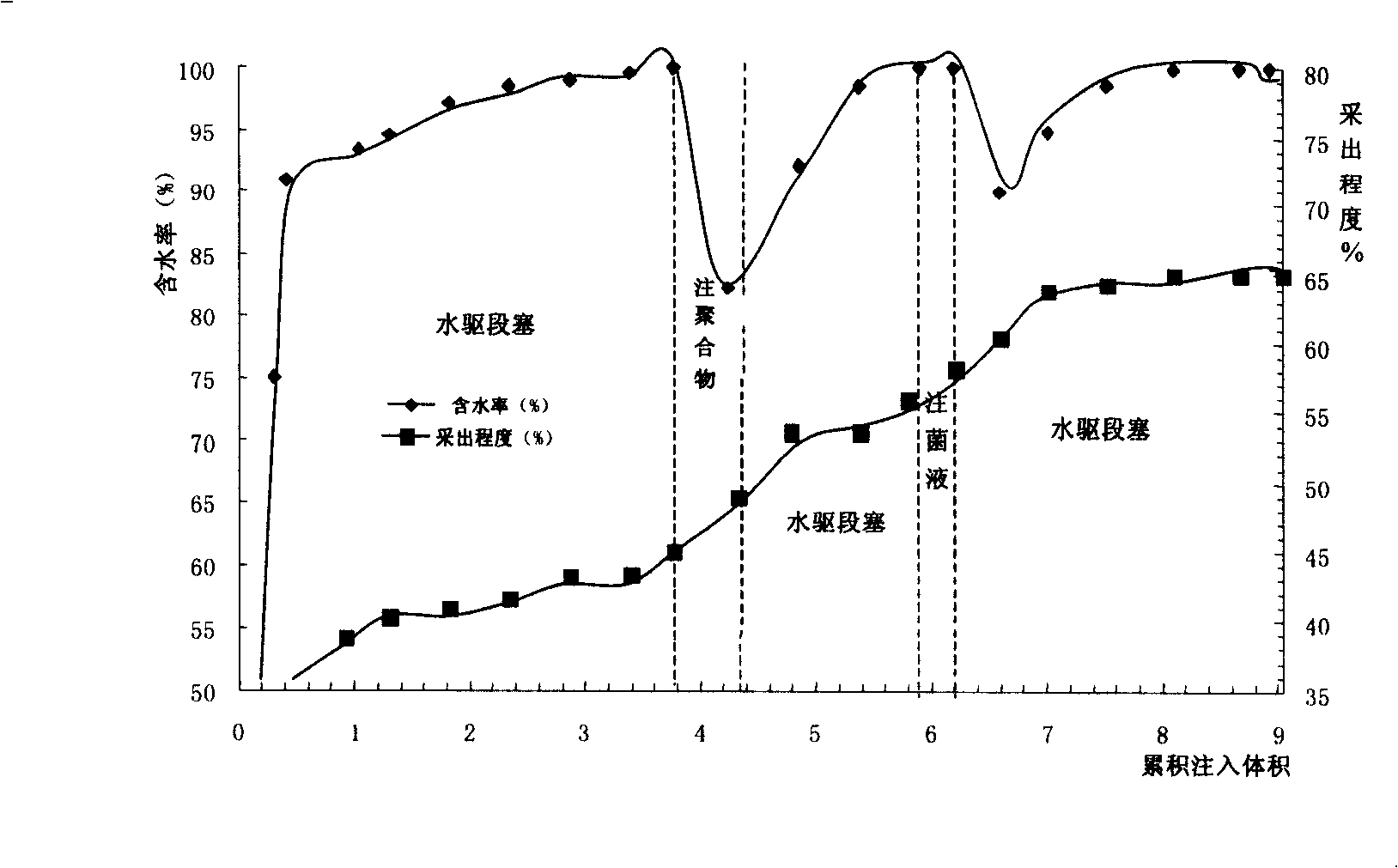

[0053] Embodiment 2, artificial cemented rock core flooding experiment

[0054] Experimental model: The experimental models are all artificial heterogeneous cemented cores, the coefficient of variation Vk=0.72, the model length cm=31.131.3, and the cross-sectional area cm 2 =12.38-12.46.

[0055] Experimental water, oil, bacteria liquid:

[0056] The saturated water used in the experiment is brine artificially prepared according to the average formation water of Daqing Oilfield (the formula is: NaCl 0.3977% CaCl 2 0.0028%, MgCl 2 6H2O 0.0046%, Na 2 SO 4 0.0093%, NaHCO 3 0.2634%), the mineralization degree is 6778mg / L.

[0057] The oil used in the experiment is the crude oil taken from Well-J5--P25 in North 2 Area of Daqing Oil Production No. 3 Plant. The viscosity of the crude oil after dehydration is 47.2mPa·s.

[0058] The injection water is the injection water of the polymer injection station of Daqing Oil Production No. 3 Plant.

[0059] Bacterial liquid used i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com