Waste water heat energy recovery system

A technology for heat energy recovery and waste water, applied in the direction of filtration circuit, indirect heat exchanger, heat exchanger type, etc., can solve the problems of filter backwashing, waste of water resources, pollution, etc., to improve heat exchange efficiency and reduce waste water Emissions and production cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

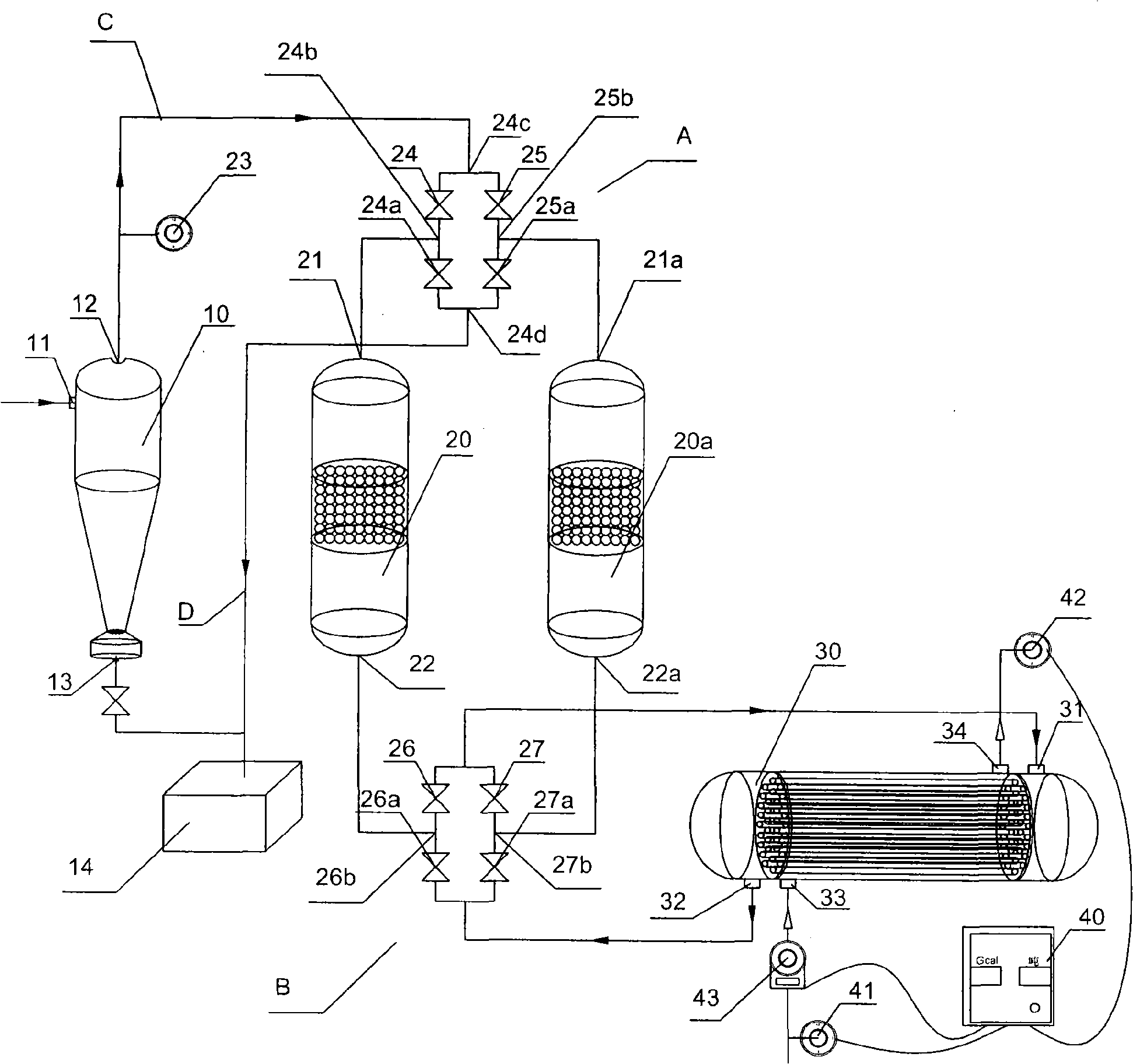

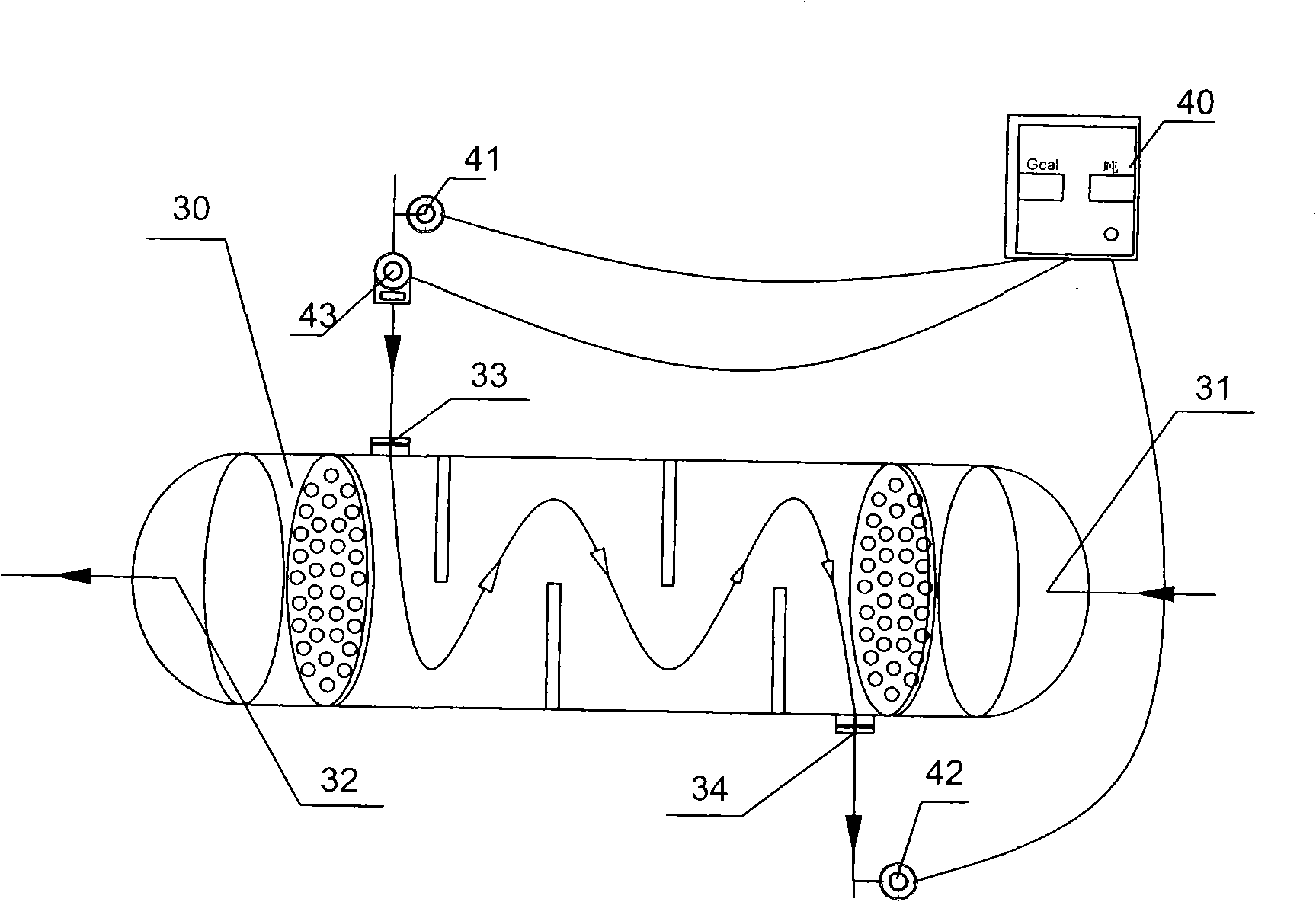

[0018] The substantive features of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0019] figure 1 The flow direction pointed by the middle arrow is the process flow direction of the whole equipment, the solid arrow is the flow direction of hot wastewater, and the hollow arrow is the flow direction of cold water. The medium and high-temperature wastewater discharged from the factory is firstly collected centrally, and then transported by the wastewater lift pump to the primary wastewater inlet 11 of the centrifugal filter 10. Through mechanical centrifugal force separation technology, the particulate matter in the wastewater with a specific gravity larger than water is separated from the wastewater. , the foreign matter heavier than water settles at the bottom of the centrifugal filter, and as the deposited foreign matter continues to increase, the valve of the foreign matter discharge port 13 is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com