Heat radiator and method for producing the same

A technology of radiator and cooling fins, applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., to achieve the effect of enhancing overall stiffness, thickening radiation, and good thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

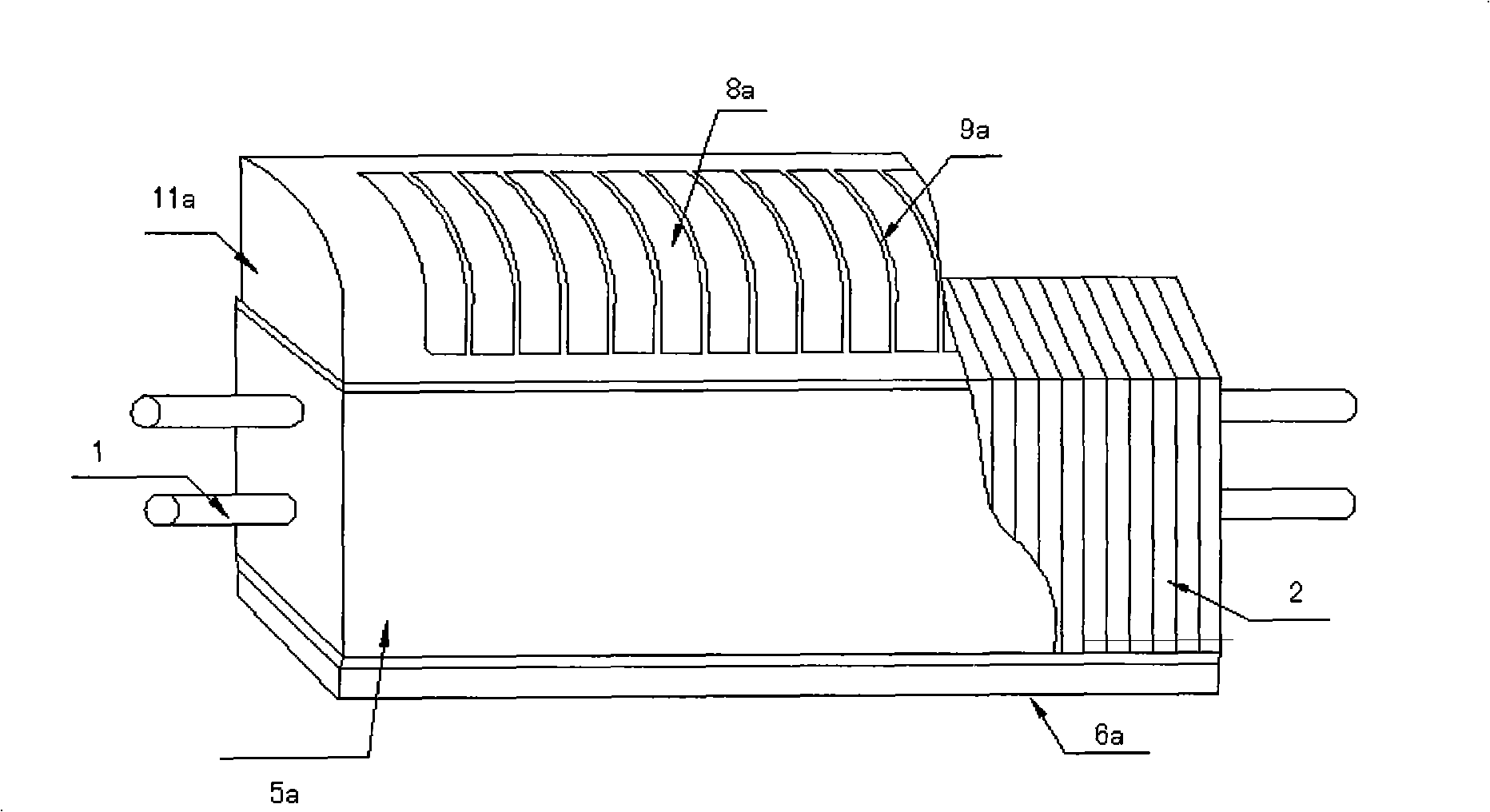

[0066] Such as figure 1 10m shown 2 The metal foil tube radiator with a strip structure for indoor heating is a structural radiator in which a bare structure radiator is placed in a shield as a core. It includes stainless steel foil pipe 1 and metal heat dissipation fins 2 as heat medium flow channels. The stainless steel foil tube 1 expands into the hole of the side panel 11a of the shield and the hole of the fin 2, forming the simplest structure of the shield, the fin and the tube.

[0067] The lower position of the radiator guard 5a is provided with an air inlet 6a, and the upper position is provided with an air outlet 8a and a grille 9a protruding from the metal foil tube 1 outside the guard side panel 11a, which is directly connected to the external piping system. The shield side panel 11a is provided with two symmetrical holes of 16.2 mm each, and the hole spacing is 80 mm corresponding to the holes of the fins 2 .

[0068] will be like image 3 The fins 2 shown are ...

specific Embodiment approach 2

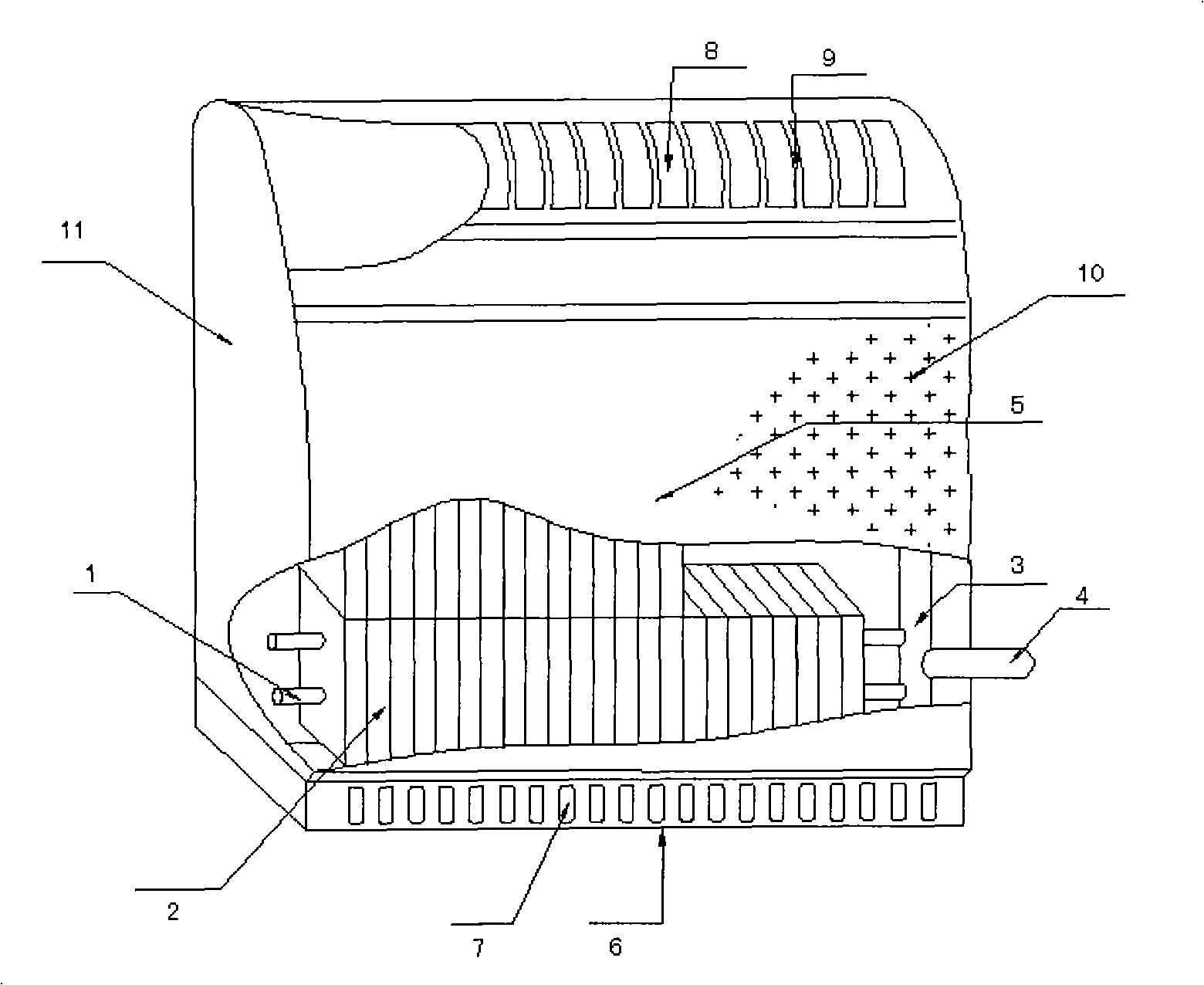

[0080] Such as figure 2 18m shown 2 The combined plate cover radiator for indoor heating is a luxurious structure assembled with shield and core separation. The metal foil tube 1 expands into the hole of the fin 2 to form an integrated structure to form a radiator core group. It consists of two or more bare structures. After the radiator is stacked up and down along the wind direction, the metal foil tubes 1 on both sides are respectively connected to the left and right sides into a channel through the connecting tube 3 . The connecting port 4 of the external pipe network system opened on the connecting pipe 3. The inlet and outlet of the radiator can be set on both sides respectively, also can be set on the same side, and can be set in any direction interface, so as to form the circulation of heat medium and working medium.

[0081] First take 2 stainless steel foil tubes 1 with a diameter of Φ15.8mm and a thickness d of 0.185mm, and arrange the fins 2 with opening holes a...

specific Embodiment approach 3

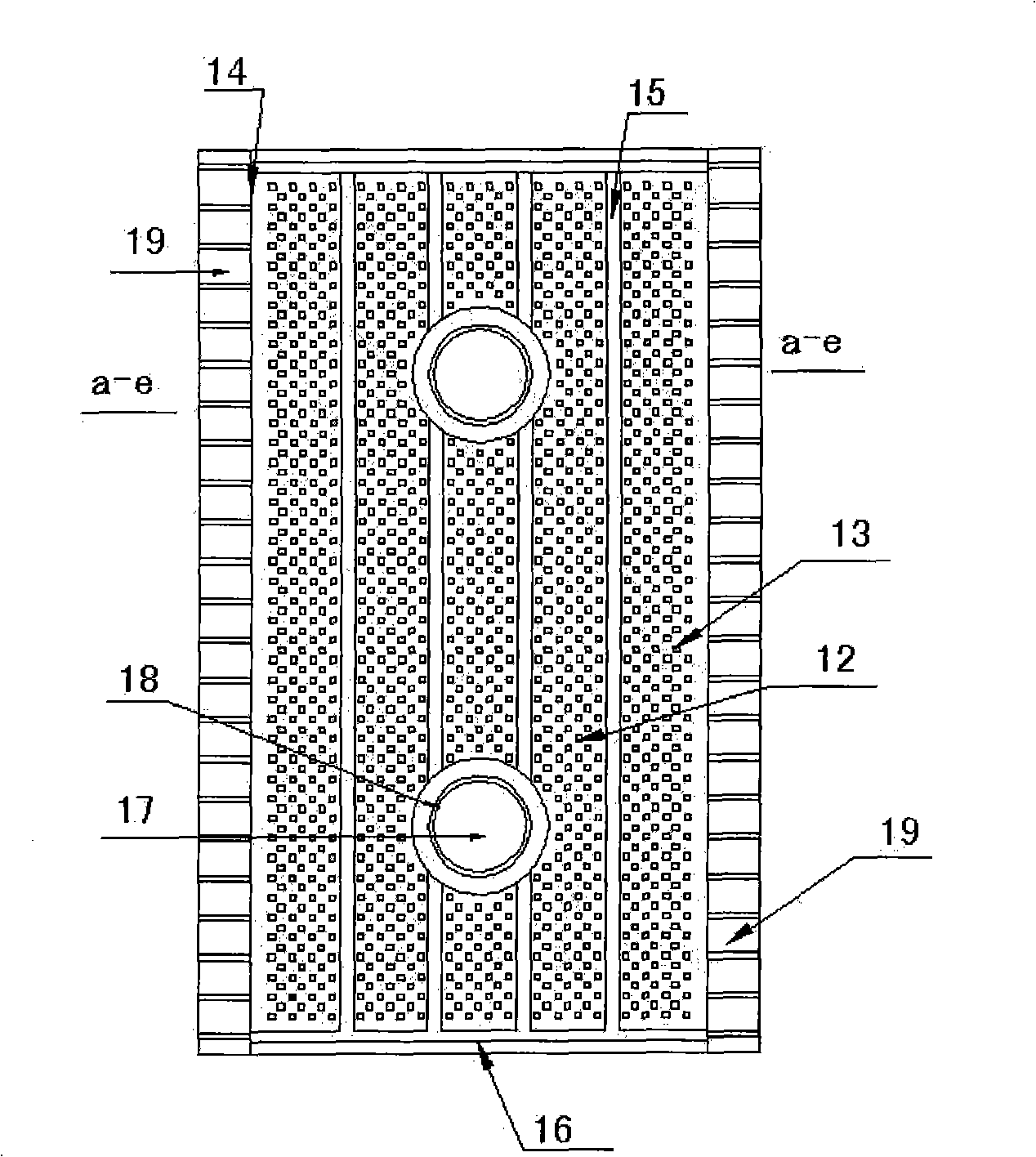

[0097] Such as Figure 9The metal foil tube heat sink with a coverless structure shown is made of metal plates with holes 17, hole flanges 18 and fins 2 evenly arranged on the metal foil tube with a thickness of 50-200 μm at a distance of 3-20 mm. 1, through the expansion tube interference combination into a shroudless radiator.

[0098] The third embodiment is suitable for heating in winter in buildings. Its heat dissipation methods include natural convection accounting for 80-95% and thermal radiation accounting for 5-20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com