Heat pipe performance detection apparatus

A detection device and heat pipe technology, which can be used in measurement devices, calorimeters, and heat measurement, etc., can solve the problems of increasing mass production of detection devices and labor costs, frequent reuse, and heat pipe performance variation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

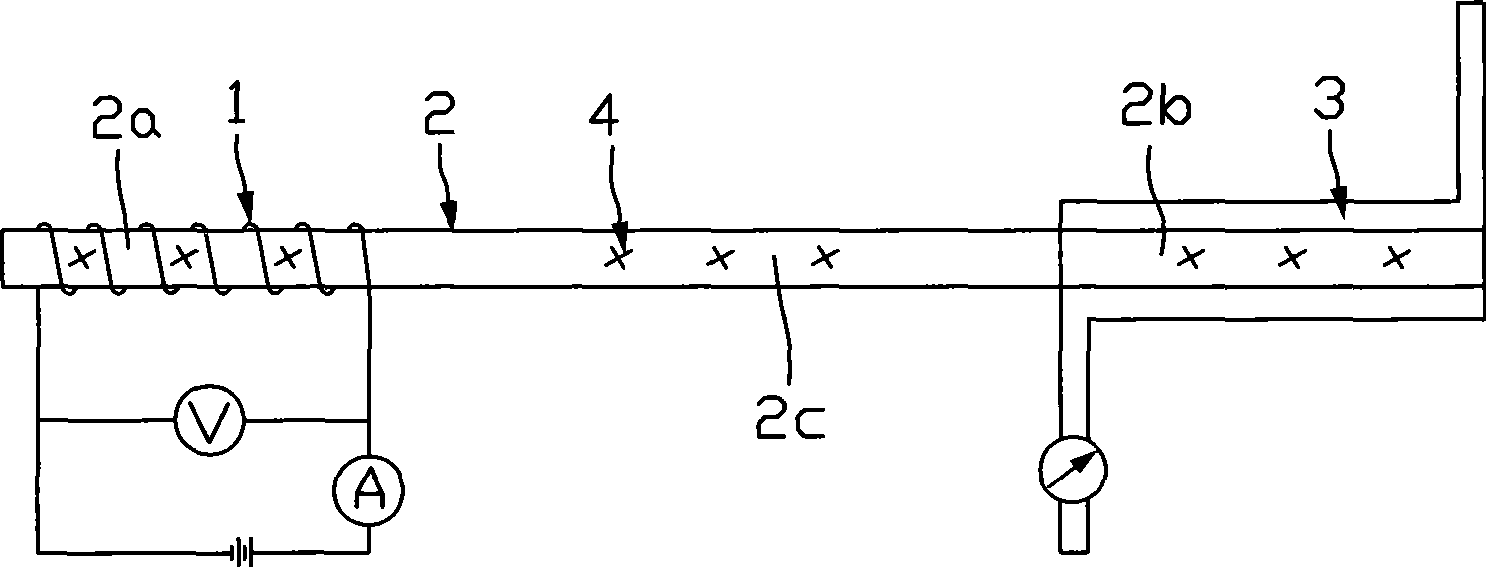

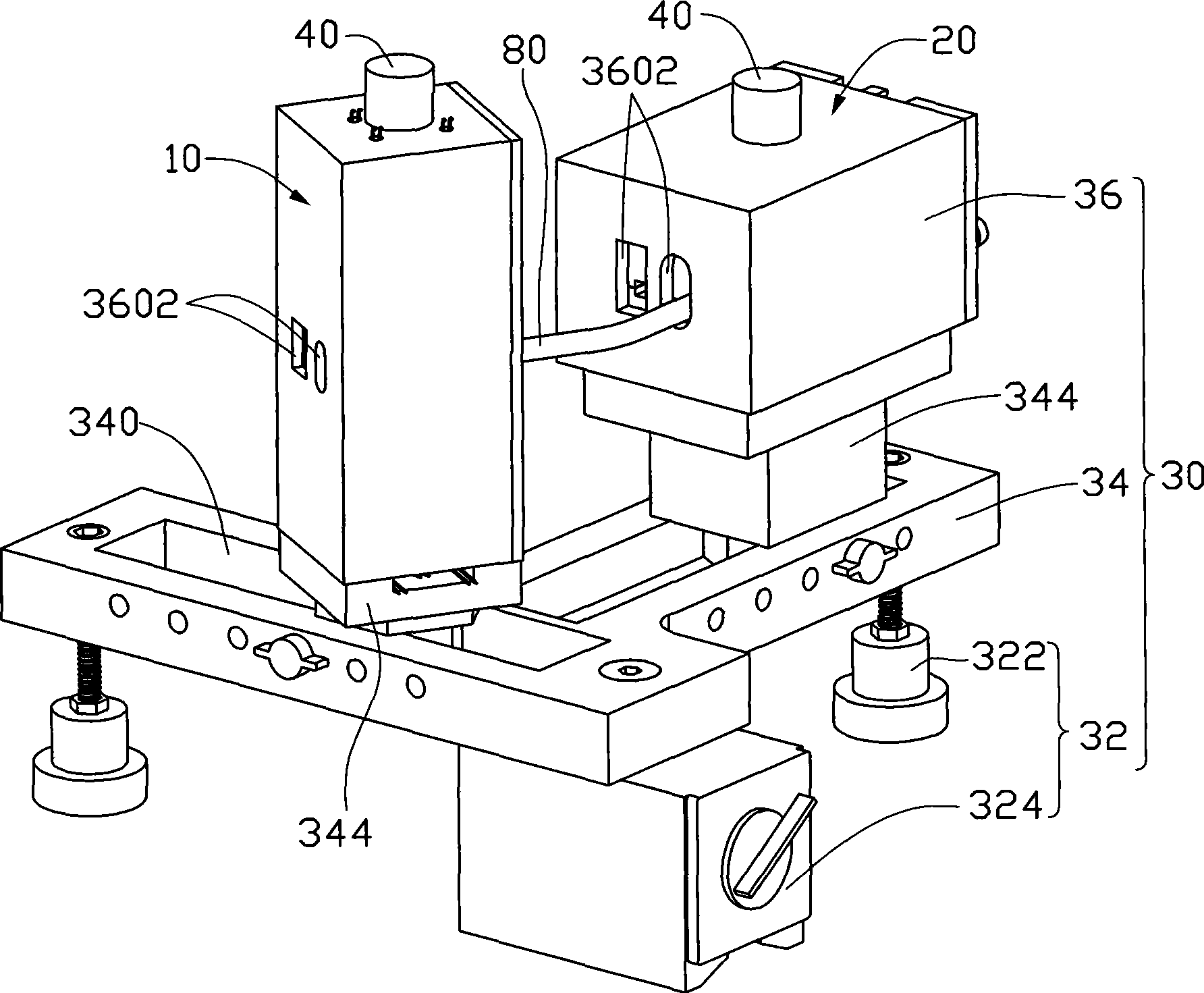

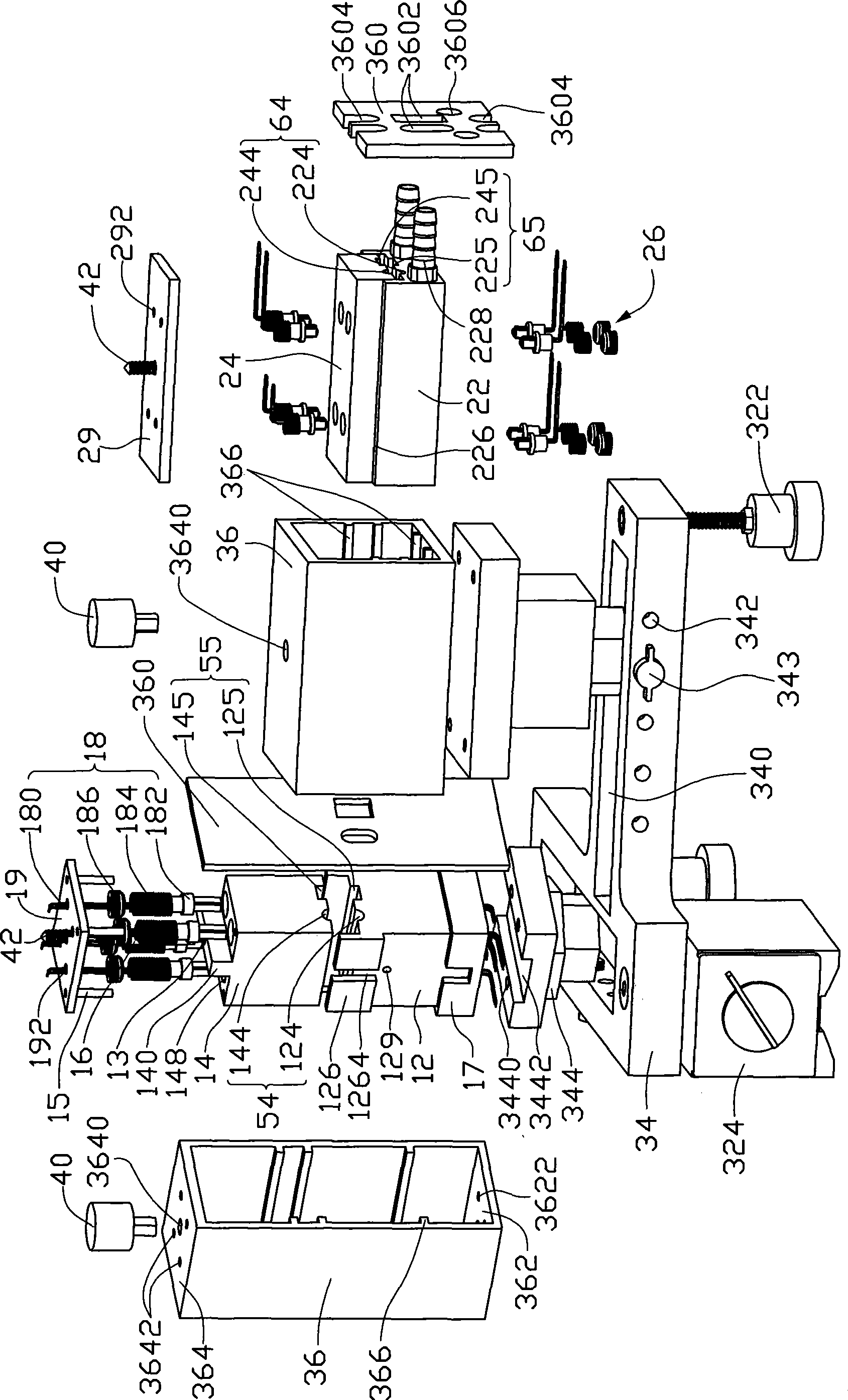

[0030] The following reference Figure 2 to Figure 11 , The heat pipe performance detection device of the present invention will be further explained.

[0031] figure 2 Is a three-dimensional schematic diagram of the appearance of the first embodiment of the heat pipe performance detection device of the present invention, image 3 for figure 2 A three-dimensional exploded schematic diagram of Figure 4 for figure 2 A three-dimensional schematic diagram of the appearance of the fixed part of the heating assembly, Figure 5 for Figure 4 A three-dimensional exploded schematic diagram of. The detection device mainly includes a heating component 10, a heat dissipation component 20 and a supporting base 30. among them:

[0032] The heating assembly 10 includes a fixed part 12 and a movable part 14. The fixed part 12 is a fixed part that is locked to a stable platform such as a test table or other supporting mechanism. At least one of the fixed portion 12 and the movable portion 14 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com