Translucent thin-film solar cell module and manufacturing method thereof

A technology of solar cells and manufacturing methods, applied in photovoltaic power generation, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of expensive related equipment, metal particle pollution, and affecting process yield, so as to improve process yield and solar cell Efficiency, the effect of improving light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

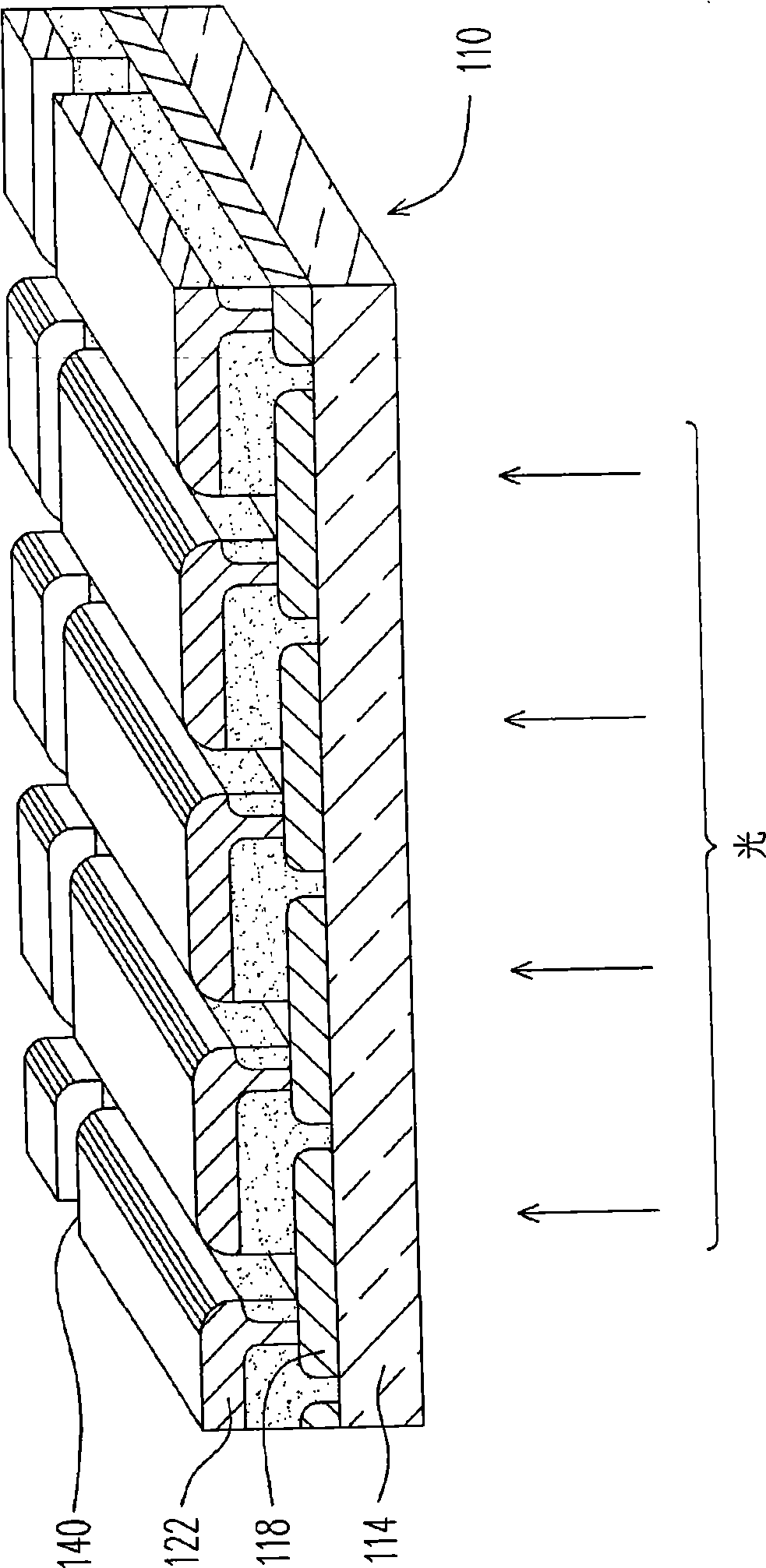

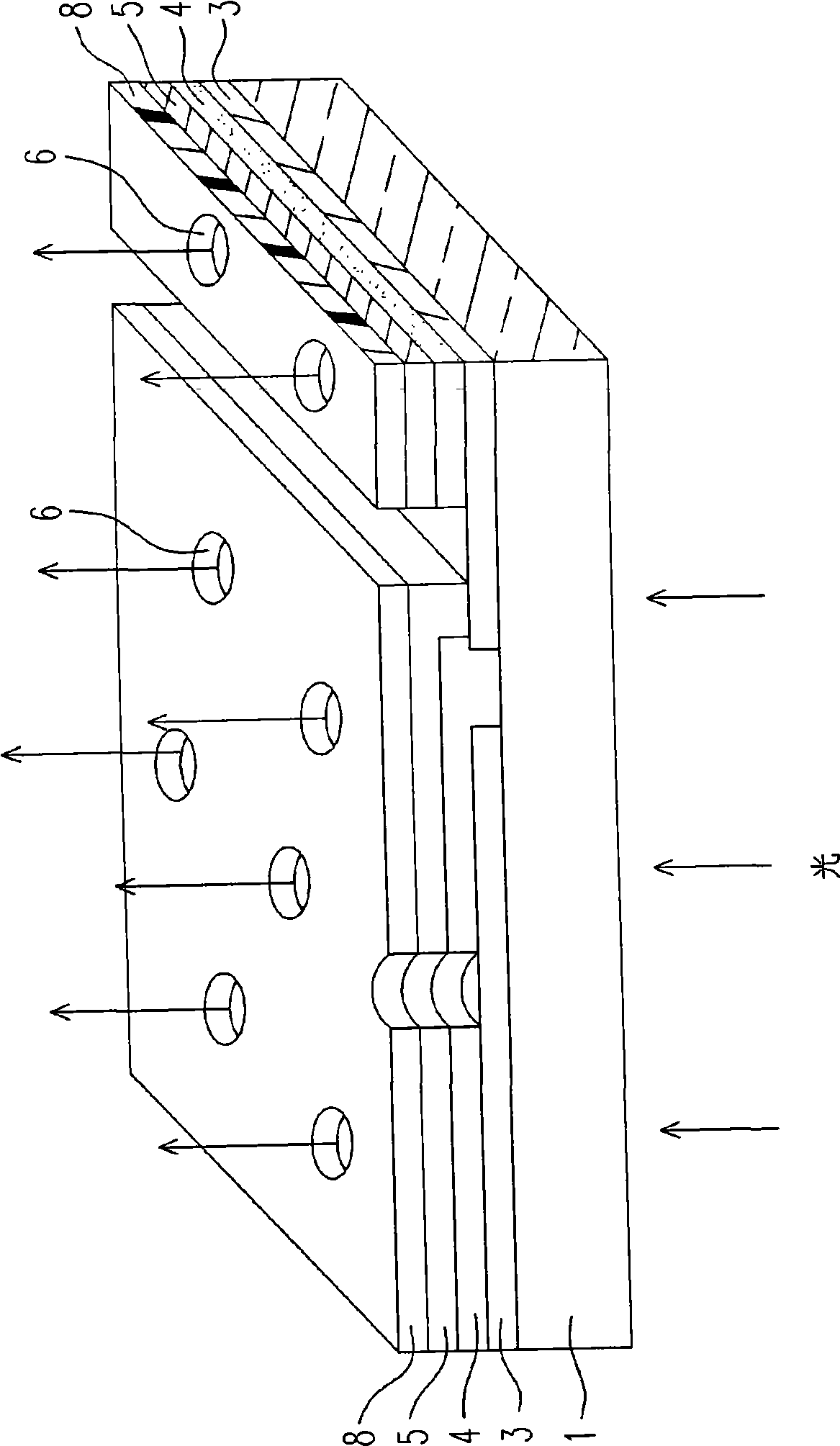

[0045] 4 to 9 are schematic flowcharts of a manufacturing method of a light-transmissive thin-film solar cell module according to an embodiment of the present invention. Wherein, the sub-figures (a) and (a') of Fig. 4 to Fig. 9 are schematic diagrams showing top views respectively, and sub-figures (b) and sub-figures (b') are schematic cross-sectional views along the section line II' , sub-figure (c) is a schematic cross-sectional view along the section line II-II'.

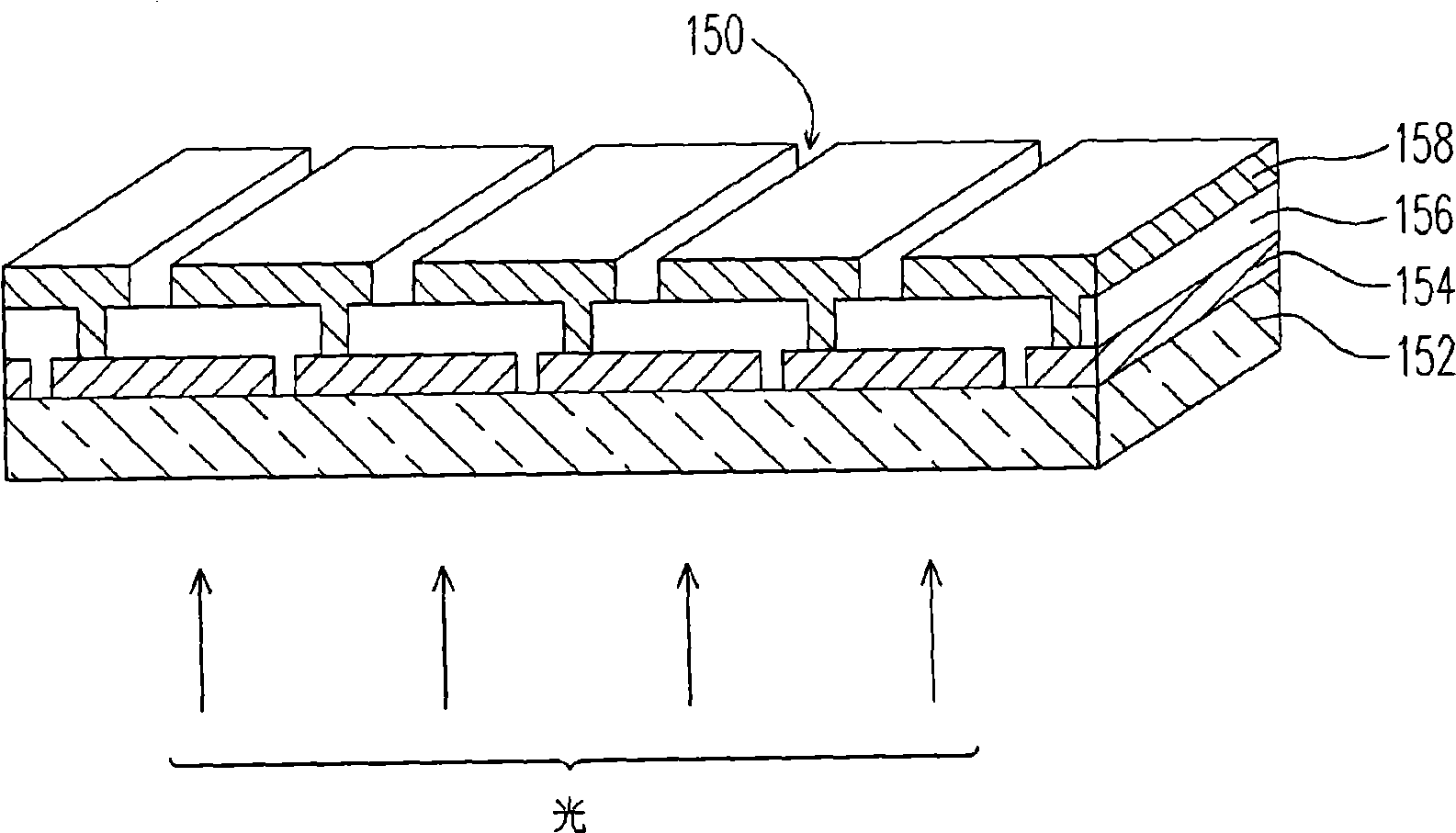

[0046] First, please refer to FIG. 9(a), FIG. 9(b), FIG. 9(b') and FIG. 9(c), the light-transmissive thin-film solar cell module 400 of this embodiment is composed of a plurality of cells connected in series ( cell) 401. These batteries 401 are composed of a first electrode 470 , a photoelectric conversion layer 414 and a second electrode 480 . These cells 401 are arranged in an array. The batteries 401 in the columns are separated by the X-direction cutting lines 422 and 408 ; the batteries 401 in the rows ar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap