Electronic power-saving device for three phase sewing machine

A technology for saving electricity and sewing machines, which is applied to sewing equipment, sewing machine components, and control devices for sewing machines, etc., can solve the problems of high electricity bills, tight electricity supply, and waste of electricity in enterprises, and achieves energy saving, current balance, and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Further detailed description will be made below in conjunction with the accompanying drawings.

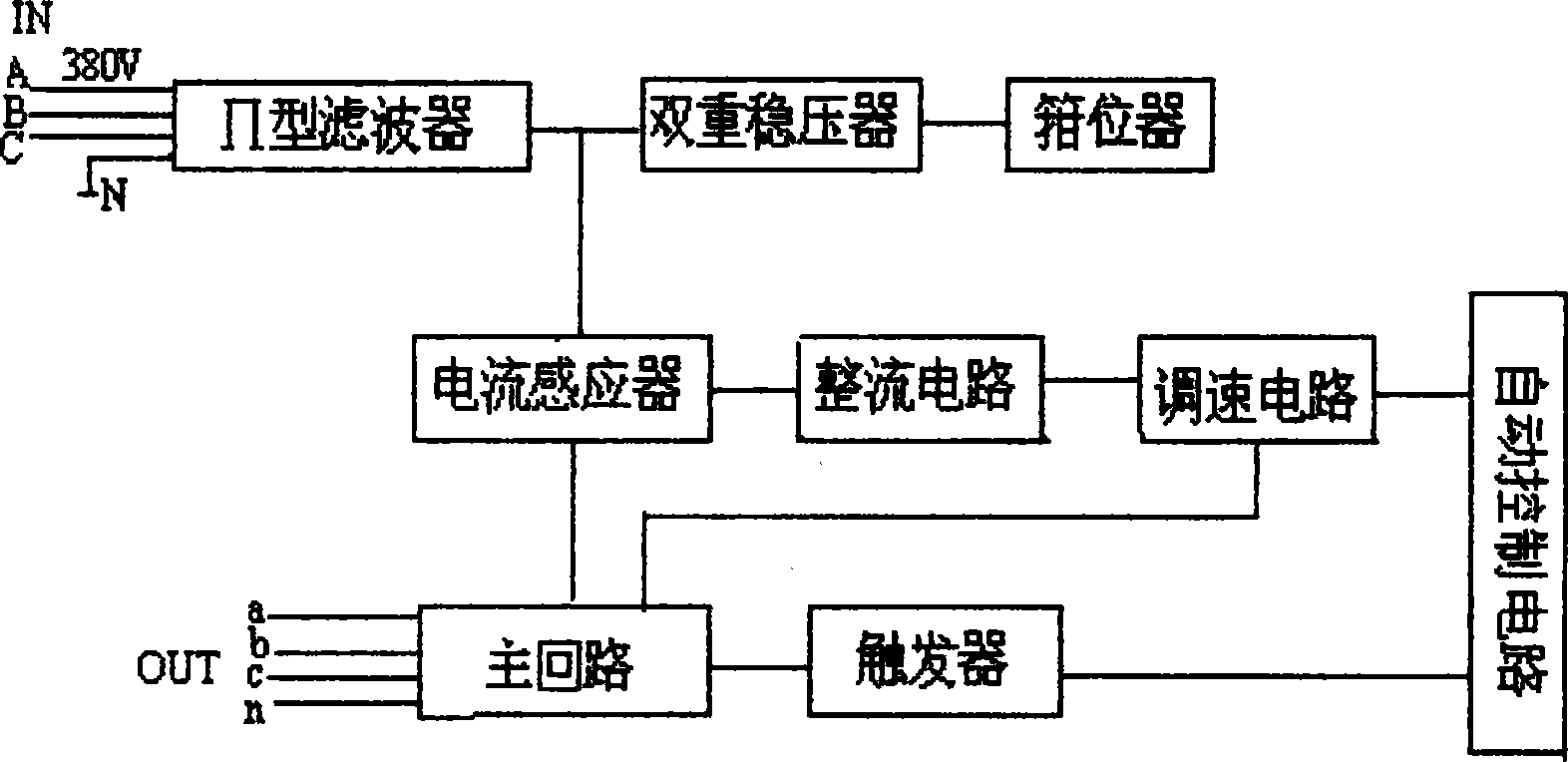

[0012] Such as figure 1 The present invention shown is composed of Π-type filter, dual voltage regulator, clamper, current inductor, rectifier circuit, speed regulating circuit, automatic control circuit, trigger and main circuit.

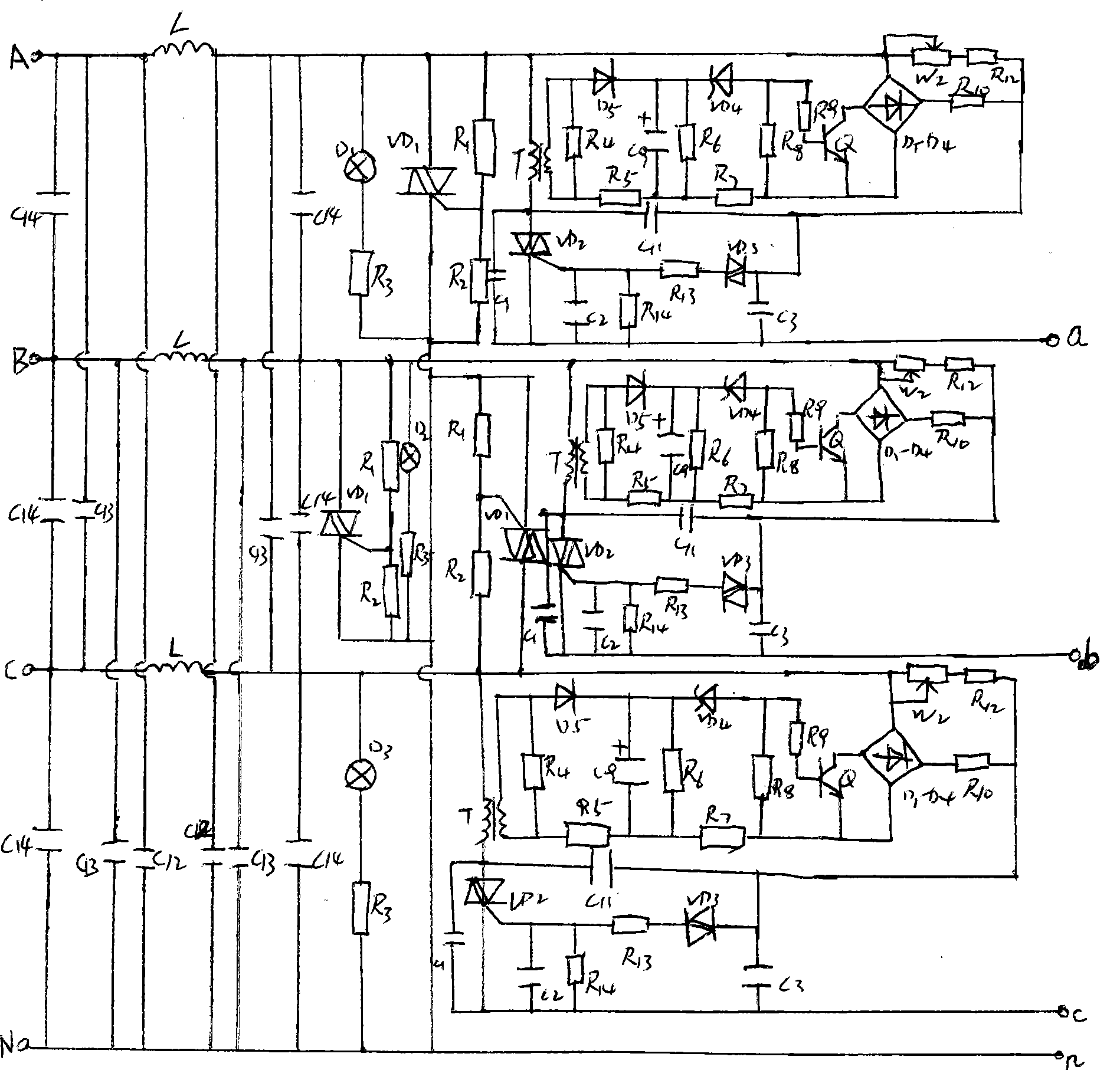

[0013] The preferred embodiment of the present invention is: as figure 2 In the circuit shown, the LC circuit forms a Π-type filter. Filtering is performed by a filter, allowing components of a given frequency to pass while blocking components of other frequencies. The transient voltage suppressor is composed of a piezoresistor, and the piezoresistor and TVP tube form a double voltage regulator. The clamper current suppression protection circuit includes a bidirectional TVP tube, which together form a fast clamping voltage and suppresses the instantaneous current protection circuit, which is characterized by large transient power, low enough ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com