Method for preparing ZnO and CdO heterogeneous nanostructured oxide material

A nanostructure and oxide technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve the problems of inability to form composites, and the catalytic activity is not improved. To achieve the effect of improving photocatalytic activity and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

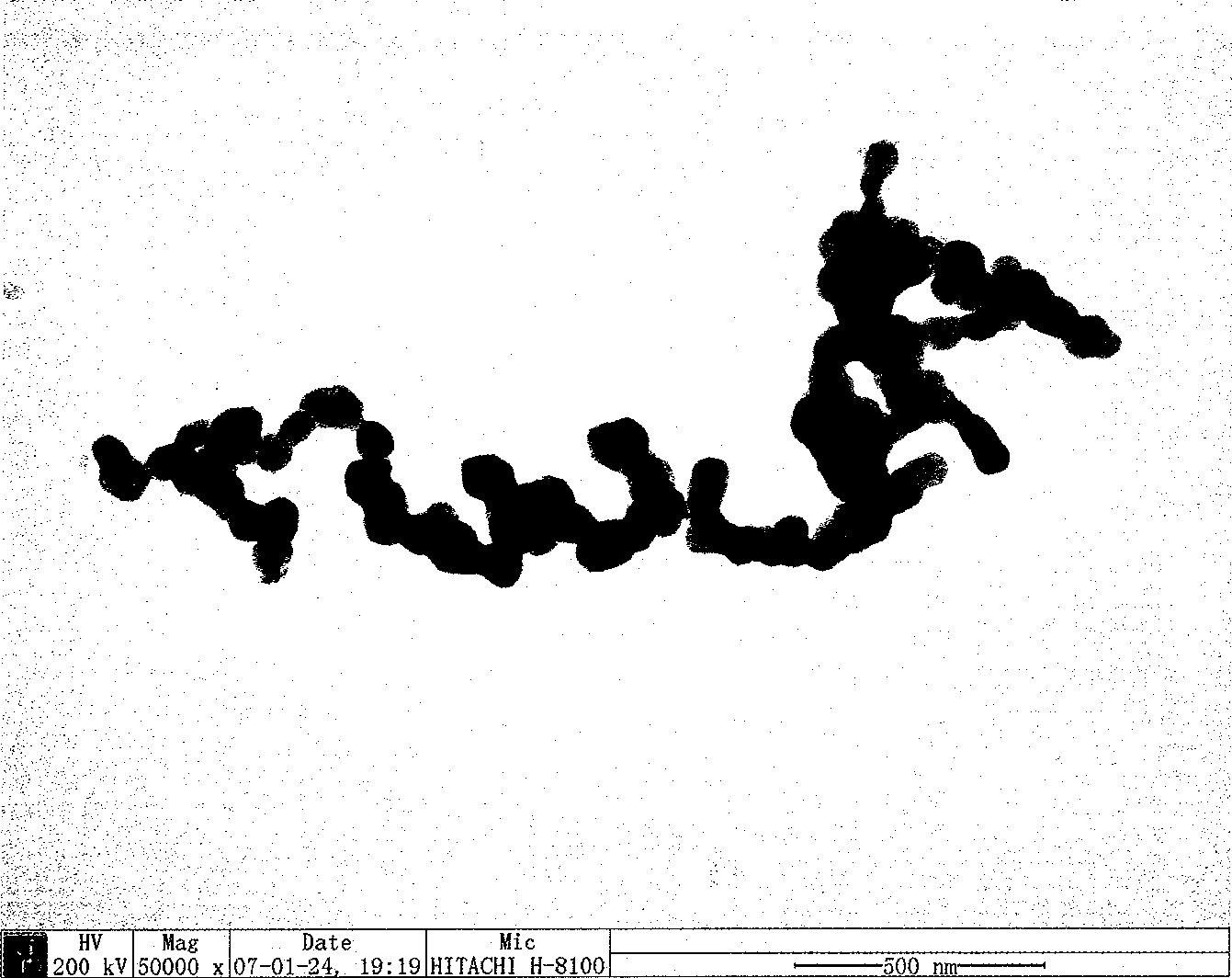

[0025] Example 1: Preparation and Characterization of ZnO / CdO with Heterogeneous Nanostructure

[0026] Weigh 2.616g Zn powder, add dilute sulfuric acid solution 400cm 3 , heated in a water bath to keep the reaction temperature at 60-65°C until no more hydrogen is produced, and Zn and ZnSO are obtained 4 solution. Discard the supernatant, add Cd(NO 3 ) 2 Solution 200cm3 , slowly dripping Na under stirring 2 CO 3 Solution 250cm 3 , The dropping speed is 2-3 drops / second. After the reaction is completed, filter with suction, wash the precipitate with water and ethanol, and dry at 60°C for 8-12 hours to obtain a uniform mixture of Zn-CdCO3. Then put it in a muffle furnace to program the temperature (5-10° C. / min) to 600° C., and keep it warm for 1.5 hours to prepare an oxide with a particle size of 60-80 nm and a ZnO / CdO heterogeneous nanostructure.

[0027] XRD analysis of the product obtained shows that the product is composed of ZnO and CdO phases, see Figure 5 . Th...

Embodiment 2

[0028] Example 2: Preparation and Characterization of ZnO / CdO with Heterogeneous Nanostructure

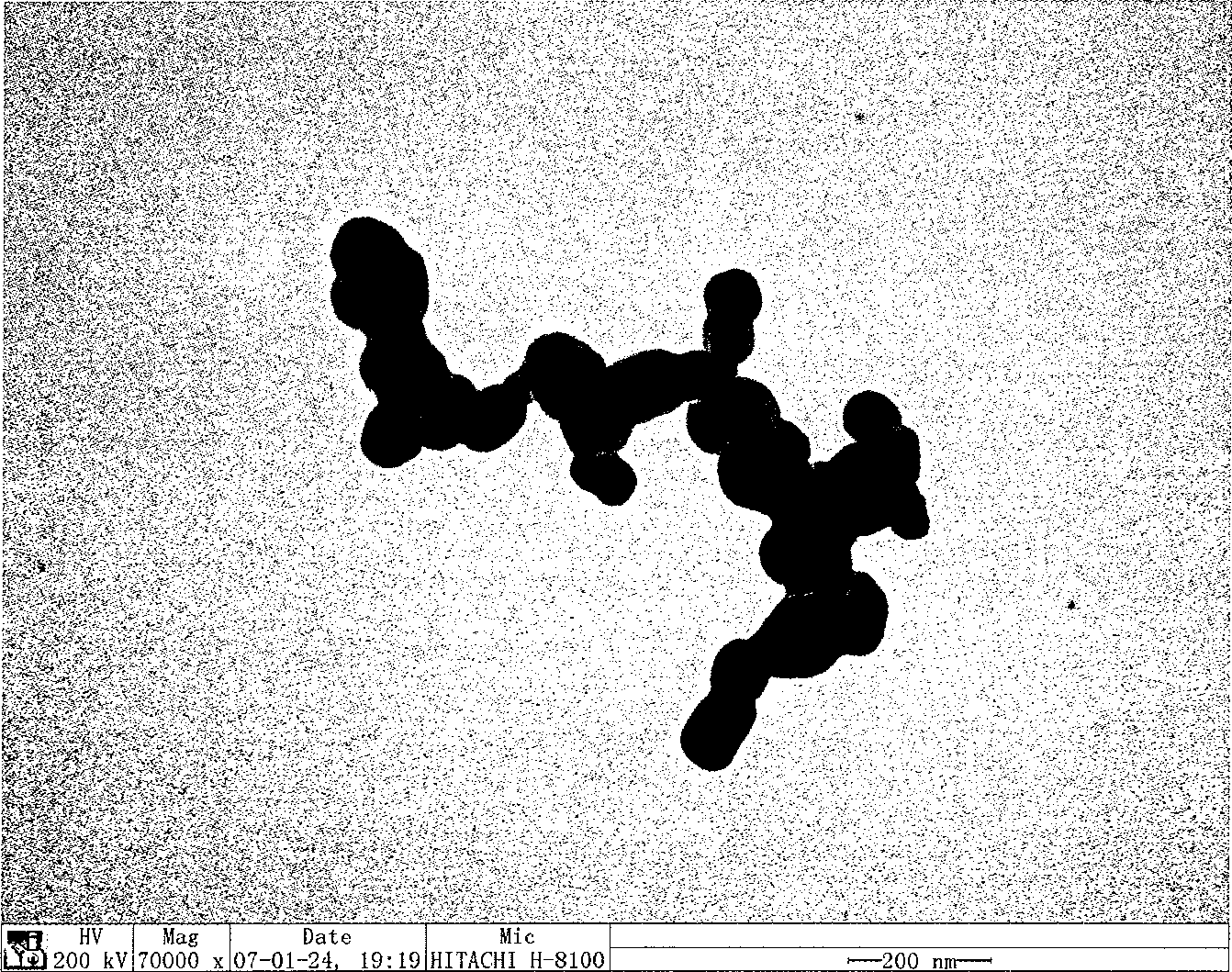

[0029] Raw material and its consumption, preparation process are the same as embodiment 1, just heat treatment process is: the Zn-CdCO 3 The homogeneous mixture is placed in a muffle furnace and the temperature is programmed to rise (5-10°C / min) to 700°C, and then kept for 3 hours to prepare an oxide with a particle size of 300-400nm and a heterogeneous nanostructure of ZnO / CdO.

[0030] image 3 TEM picture of ZnO / CdO prepared by heat treatment at 700℃ for 3h, Figure 4 for correspondence image 3 The EDS spectrum. EDS was used to analyze the composition of the micro-regions at the junction of the particles (the atomic percentages were O: 22.40%, Cd: 51.60%, and Zn: 26.00%, respectively), indicating that the product was a ZnO / CdO heterostructure.

Embodiment 3

[0031] Example 3: Preparation of ZnO / CdO with heterogeneous nanostructure

[0032] Preparation process is the same as embodiment 1 or embodiment 2, just the Na in embodiment 1 or 2 2 CO 3 The solution is changed to add dilute ammonia solution to obtain Zn-Cd(OH) 2 Homogeneous mixture; the same product as in Example 1 or 2 can be prepared through heat treatment, and XRD analysis shows that the product is also composed of ZnO and CdO phases.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com