Plastic extrusion and welding heat-insulation plate with inner lining and assembly method thereof

A technology of extrusion welding and assembly method, which is applied in the direction of packaging, transportation and packaging, transporting passenger cars, etc., can solve the problem of weak combination of foam layer and heat insulation board, complicated construction of heat insulation board on the inner wall of the refrigerator, and poor heat insulation effect and other problems, to achieve the effect of improving operating efficiency, improving heat insulation effect, and not easy to corrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

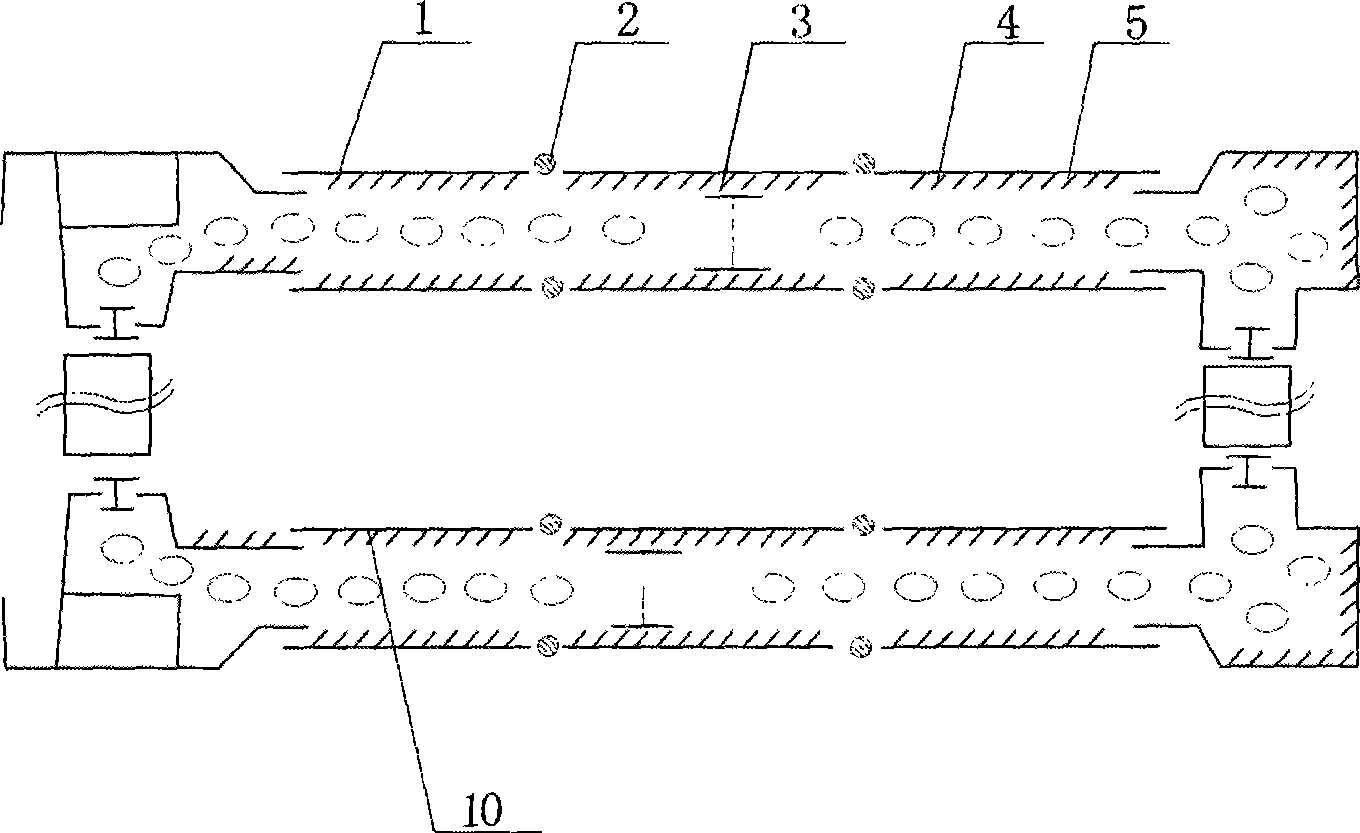

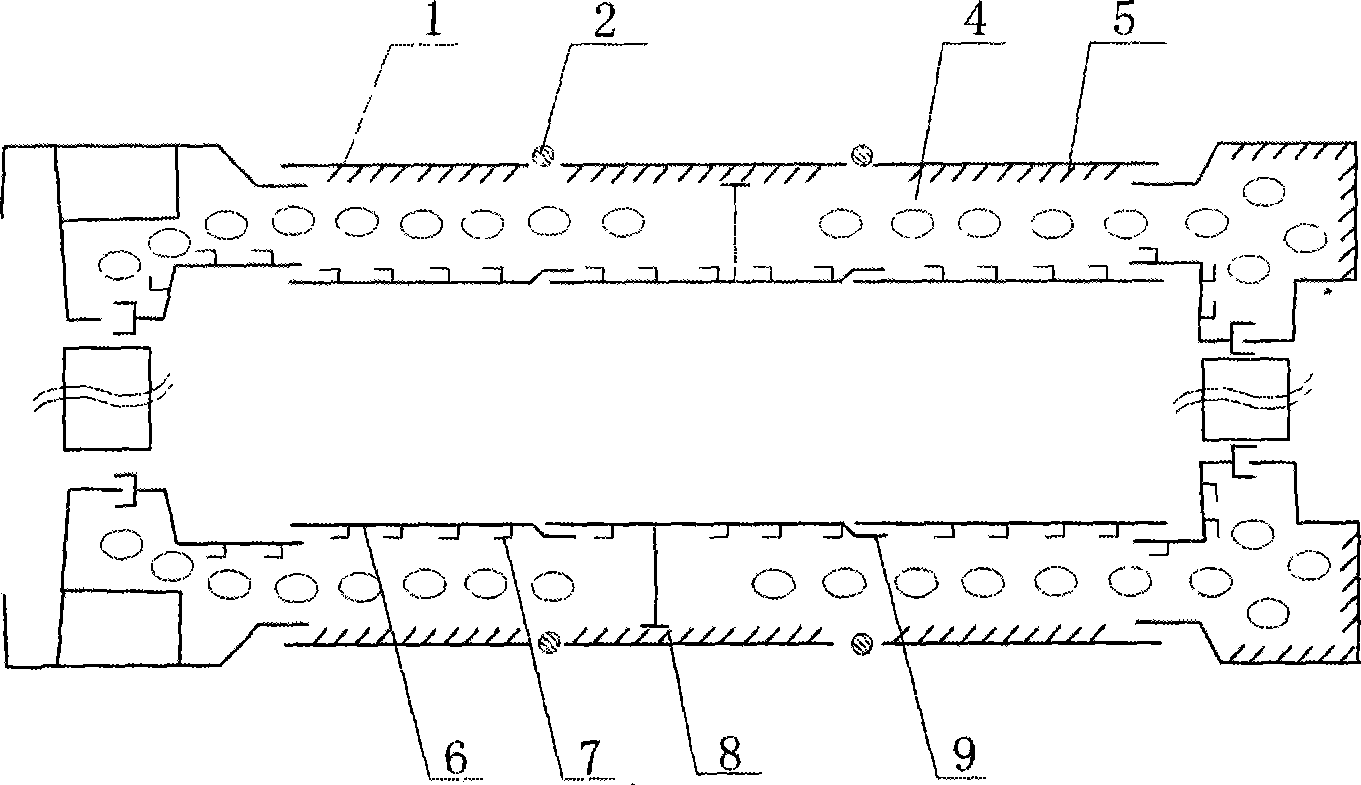

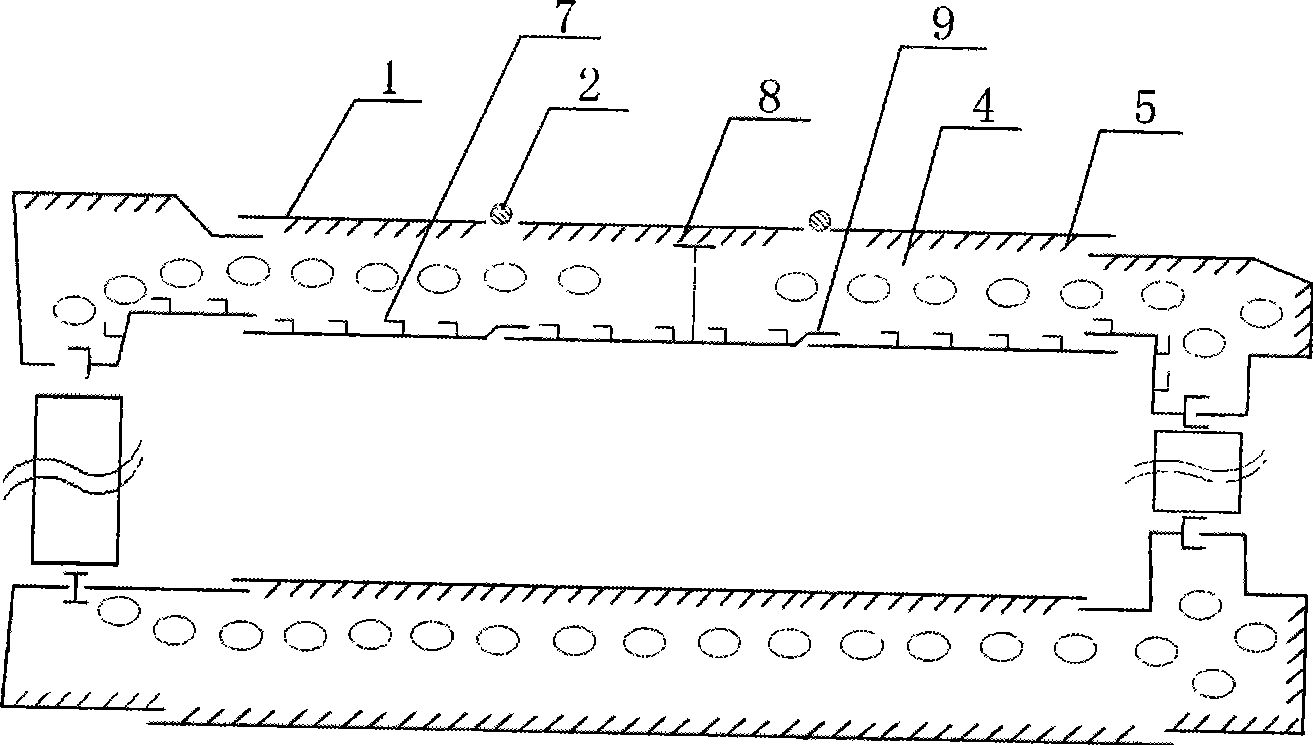

[0048] The plastic extruded and welded inner-lined heat insulation board of the present invention is used for refrigerated containers used for ocean transportation or the like. The body of a refrigerated container generally includes three parts: a metal outer layer, a non-metallic insulating foam material and an inner layer. In the prior art, the inner layer is generally a stainless steel or aluminum alloy plate, or a fiber-reinforced base plate. In order to achieve a good heat preservation effect, an insulating material is welded, glued, riveted, coated or bonded on the plate surface, and the outer layer And the inner layer is generally provided with a concave-convex insulating surface for wedging. Corrosive acrylic adhesives are used to connect the outer and inner layers. The connection of this metal layer is expensive due to the use of stainless steel and aluminum alloy materials; due to the use of the outer layer containing a variety of toxic and harmful chemicals And cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com