Protector of mine hoist

A technology of protection device and hoist, which is applied in mine lifting equipment, transportation and packaging, program control in sequence/logic controller, etc., can solve problems such as difficult handling of accidents, safety accidents, repeated loading, etc., and achieve improvement Reliability and production efficiency, reduce labor intensity, and avoid safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

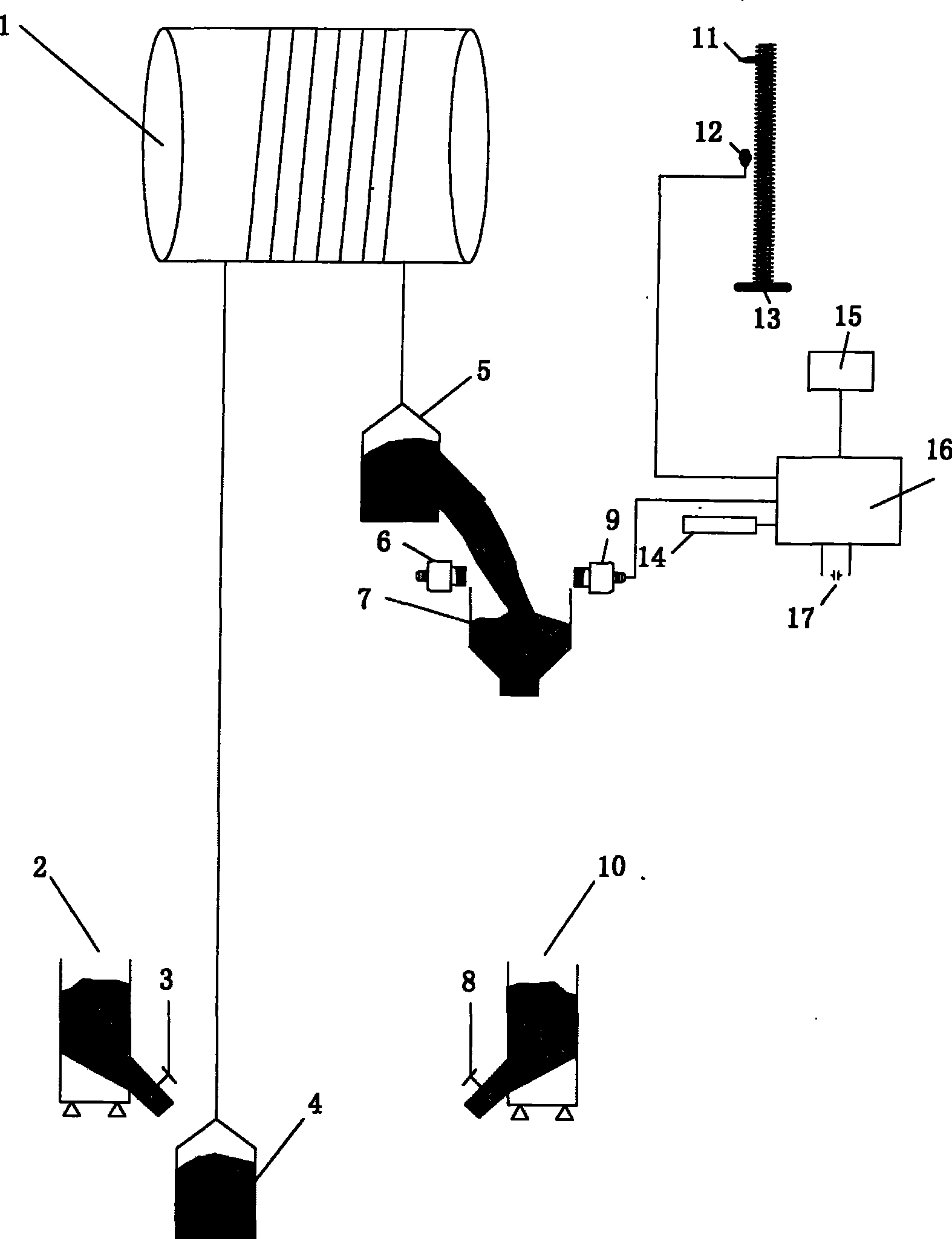

[0016] The core idea of the present invention is that the microwave transmitter 6, the microwave receiver 9, the proximity switch 12, the programmable controller 16 and the touch screen 15 of the microwave material flow device form the main shaft hoist anti-reloading protection device. The device can accurately and reliably judge whether the skip is completely unloaded by detecting the time of skip unloading material flow and the current value of the hoist, and output a control signal. If the skip is not completely unloaded, it will control the loading gate of the quantitative bucket It cannot be opened, prohibiting reloading of the skip, thus preventing reloading.

[0017] figure 1 It is a schematic diagram of the structural principle of the main shaft hoist protection device of the present invention; figure 1 As shown, the microwave transmitter 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com