Coal chemical industry wastewater treating method

A technology for coal chemical wastewater and treatment method, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of poor effluent quality and high operating costs, and achieve strong adaptability , low operating cost, good treatment effect

Inactive Publication Date: 2010-12-01

HARBIN INST OF TECH

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a coal chemical wastewater treatment method to solve the problems of poor effluent quality and high operating costs in the existing coal chemical wastewater treatment process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 1

specific Embodiment approach 2

specific Embodiment approach 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

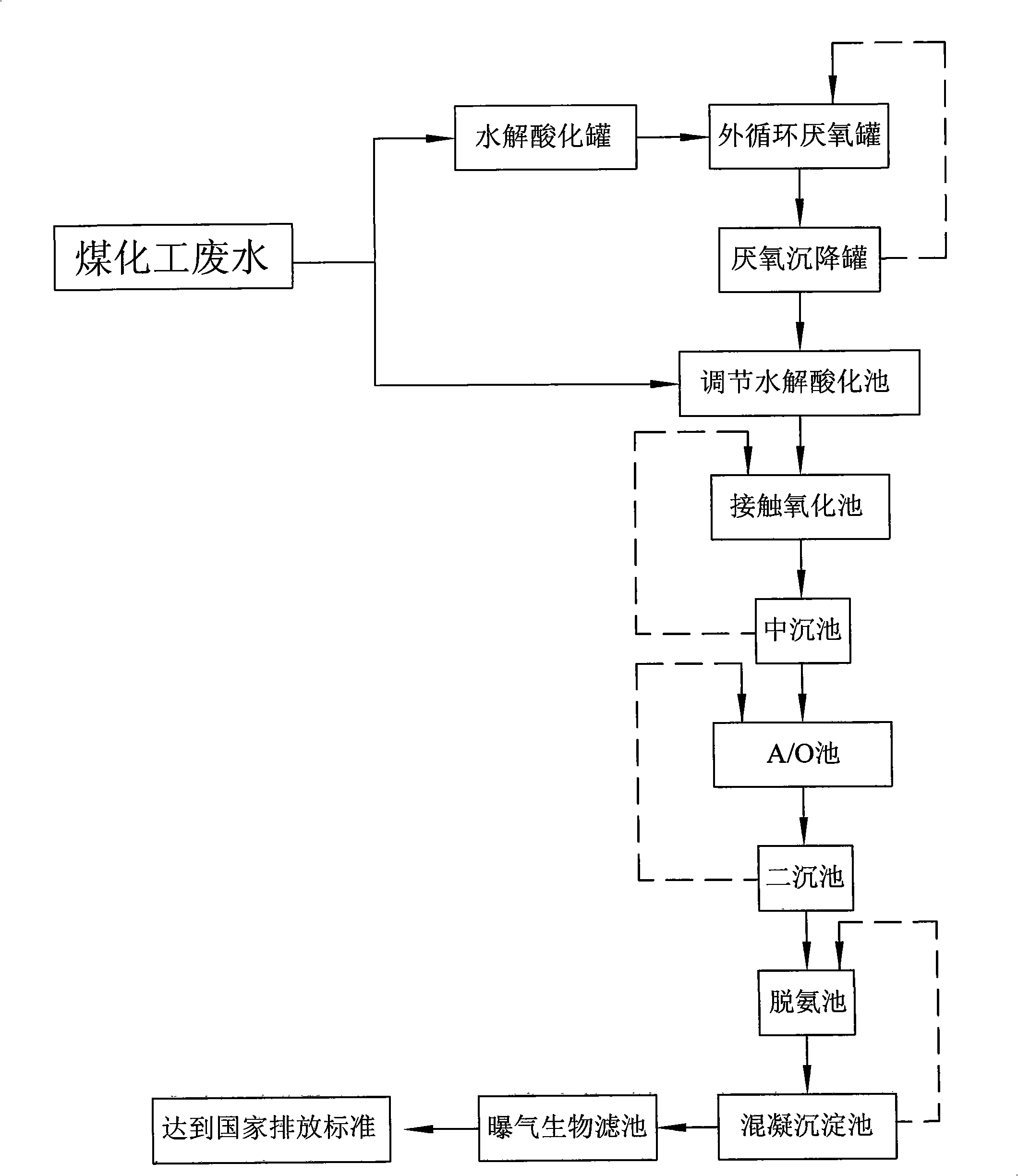

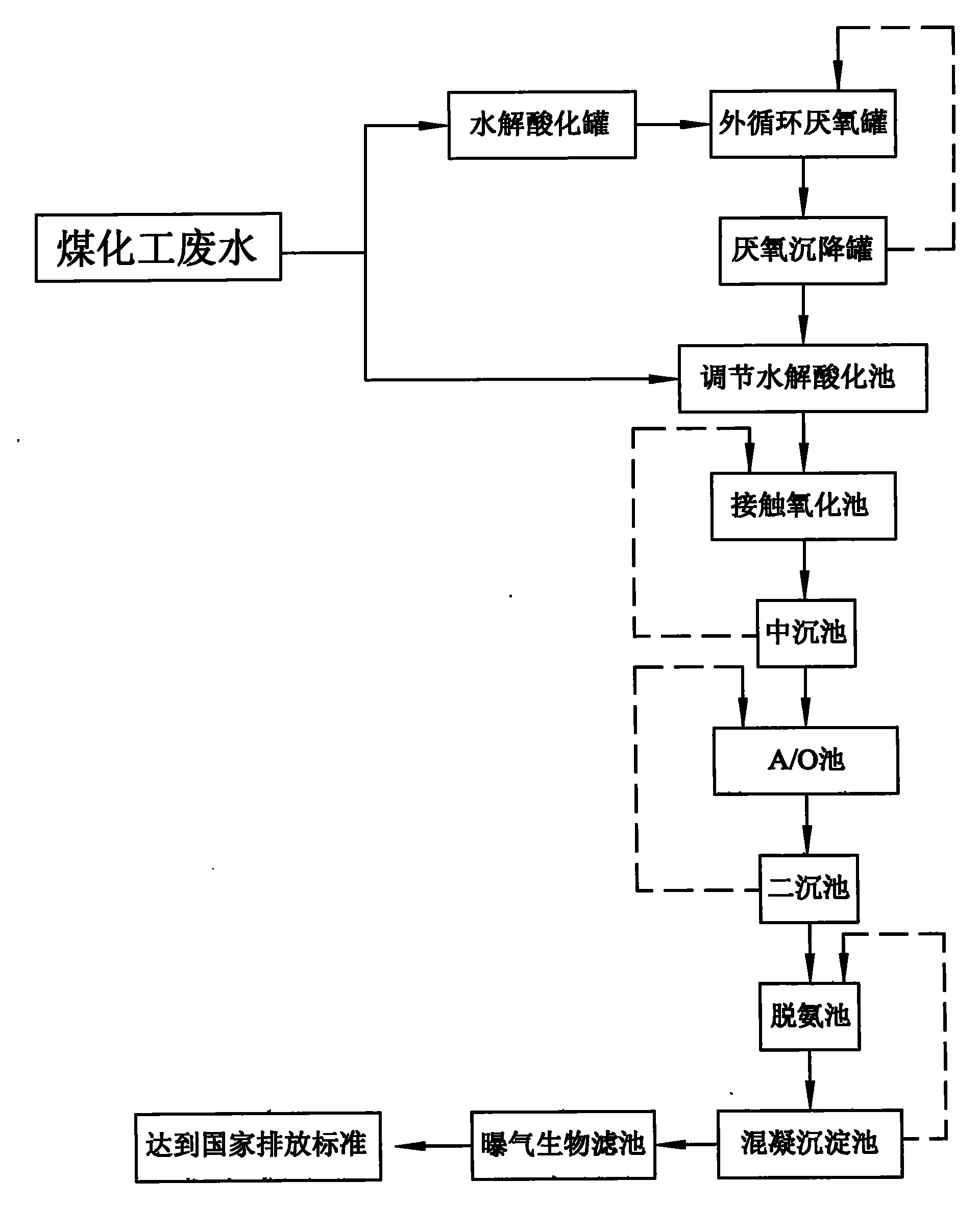

The invention relates to a coal chemical wastewater treatment method, in particular to a chemical wastewater treatment method. The invention aims to solve the problems of the chemical wastewater treatment method such as bad outlet water quality and high operational cost. The method comprises the following steps: pretreating coal chemical wastewater to be treated; then carrying out hydrolytic acidification treatment, external circulating anaerobic treatment, anaerobic sedimentation treatment, adjusting hydrolytic acidification treatment, contact oxidation treatment, sedimentation treatment, A / O treatment, sedimentation treatment, deamination treatment, coagulating sedimentation treatment and aeration biological filter tank treatment, wherein the temperature in an external circulating anaerobic tank is controlled within the scope of 32 to 35 DEG C; the hydraulic detention time is 24 to 36 h; the sludge concentration is controlled between 50 and 100 g / L; the volume load is 5 to 10 kg COD / m<3>.d ; and the pH value is controlled between 7.0 and 7.5. The invention has the advantages of flexible operation, impact load resistance, low operating cost and good treatment effect; after the coal chemical wastewater is treated by the treatment method, the outlet water quality completely can achieve the wastewater comprehensive discharge standard regulated by the State.

Description

A kind of coal chemical industry wastewater treatment method technical field The invention relates to a method for treating chemical wastewater, belonging to the field of industrial wastewater treatment. Background technique Coal chemical industry refers to the process of converting coal into gas, liquefied and solid fuels and chemicals through chemical processing using coal as raw material, including high-temperature dry distillation, low-temperature dry distillation, gasification, liquefaction, coal-to-chemicals and other coal processing products. The wastewater discharged by coal chemical enterprises is produced during the coal processing process, including coking wastewater, gasification wastewater, and liquefaction wastewater, mainly high-concentration coal gas washing wastewater. The wastewater is characterized by complex water quality, containing a large amount of phenols, polycyclic aromatic compounds and heterocyclic compounds containing nitrogen, oxygen and sulf...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C02F9/14C02F3/30C02F101/16C02F101/30

Inventor 韩洪军王伟李慧强方芳杜彦杰

Owner HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com