High voltage power fast recovery diode and manufacturing method thereof

A technology for recovering diodes and power, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., and can solve problems such as failure of parallel circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

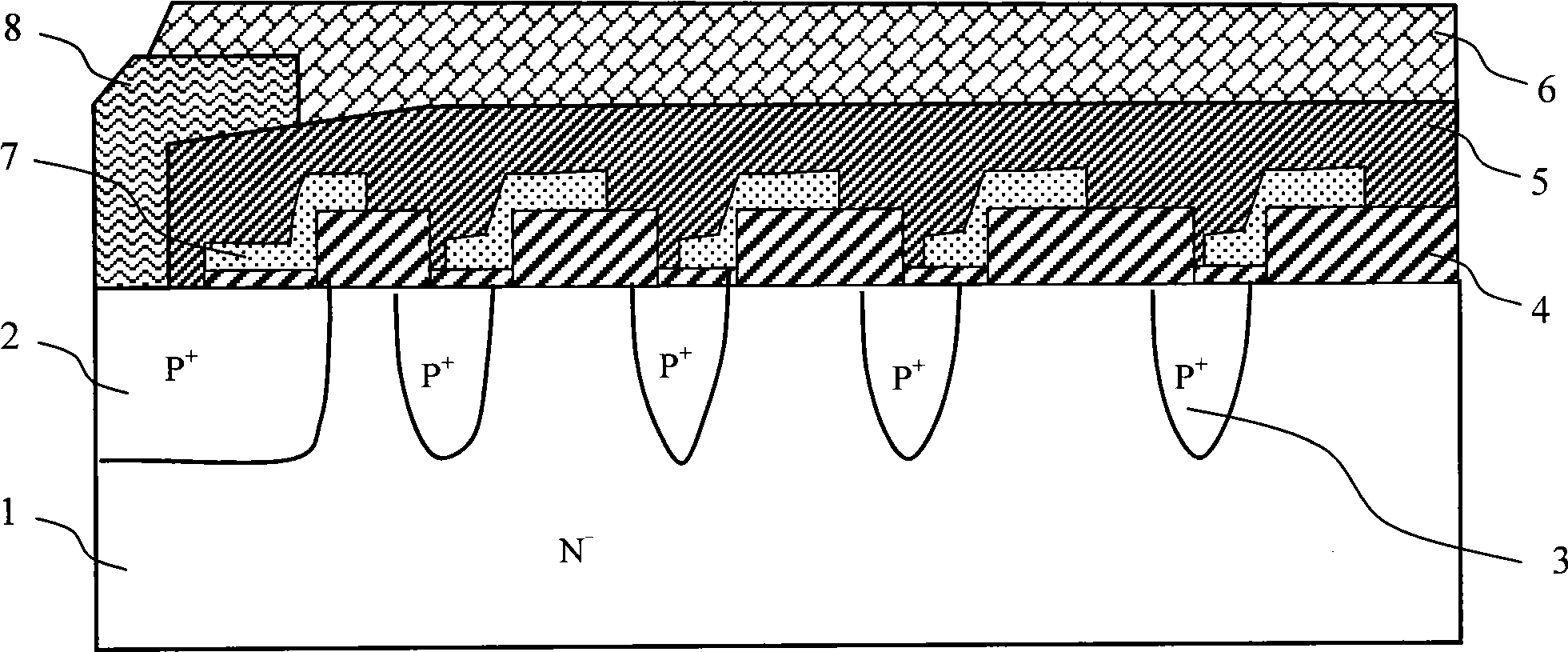

[0028] High voltage power fast recovery diode of the present invention is realized in this way, see Figure 5 As shown, the junction depth of the main junction 2 is 1-3μm, and the doping concentration is 1E16-1E18cm -3 .

[0029] The technical solution matched with this scheme is that the junction terminal is a compound field plate structure, which is composed of a phosphorus-doped polysilicon layer field plate 7 and an aluminum electrode field plate 8, and the aluminum electrode conducts with the phosphorus-doped polysilicon layer, and the aluminum electrode field plate 8 is a multi-level field plate or a stepless gradient field plate, and the dielectric layer 9 is located between the silicon high-resistance layer 1, the phosphorus-doped polysilicon layer field plate 7 and the aluminum electrode field plate 8, see Figure 5 , Figure 6 As shown, the dielectric layer 9 is composed of three parts. From the silicon high resistance layer 1 to the aluminum electrode field plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com