Selective hydrogenation desulfurization and highly-branched chain isomerous coupling modification method for faulty gasoline

A technology for hydrodesulfurization and hydromodification, which is applied in hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., can solve the problems of unsatisfactory catalyst stability and high processing cost, simplify catalyst types and improve octane value, cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The catalyst that this embodiment is used for FCC gasoline reforming processing comprises:

[0037] First-stage dealdiene—a highly selective hydrodesulfurization catalyst, based on the total weight of the catalyst: 5wt% CoO—14wt% MoO 3 —5wt%MgO—4wt%B 2 o3 / 65wt%Al 2 o 3 —7wt%TiO 2 ; The second stage contains a SAPO-11 molecular sieve-based catalyst, based on the total weight of the catalyst: 1wt% CoO—6wt% MoO 3 —3wt%NiO / 64wt%SAPO-11—22wt%Al 2 o 3 —4wt%TiO 2 .

[0038] The specific preparation steps of the first stage catalyst are as follows:

[0039] Weigh 631.83g Al(NO 3 ) 3 9H 2 O, add 819.7ml deionized water, stir to make it all dissolve, called A 1 solution;

[0040] Weigh 31.30g Ti(SO 4 ) 2 , add 357.7ml deionized water, stir vigorously to dissolve it completely, called T 1 solution;

[0041] Configure 1000ml mixed ammonia solution (NH 3 ·H 2 O and NH 4 HCO 3 The molar ratio is 8:1) as the alkali precipitant, measure 180mL of the alkali precipi...

Embodiment 2

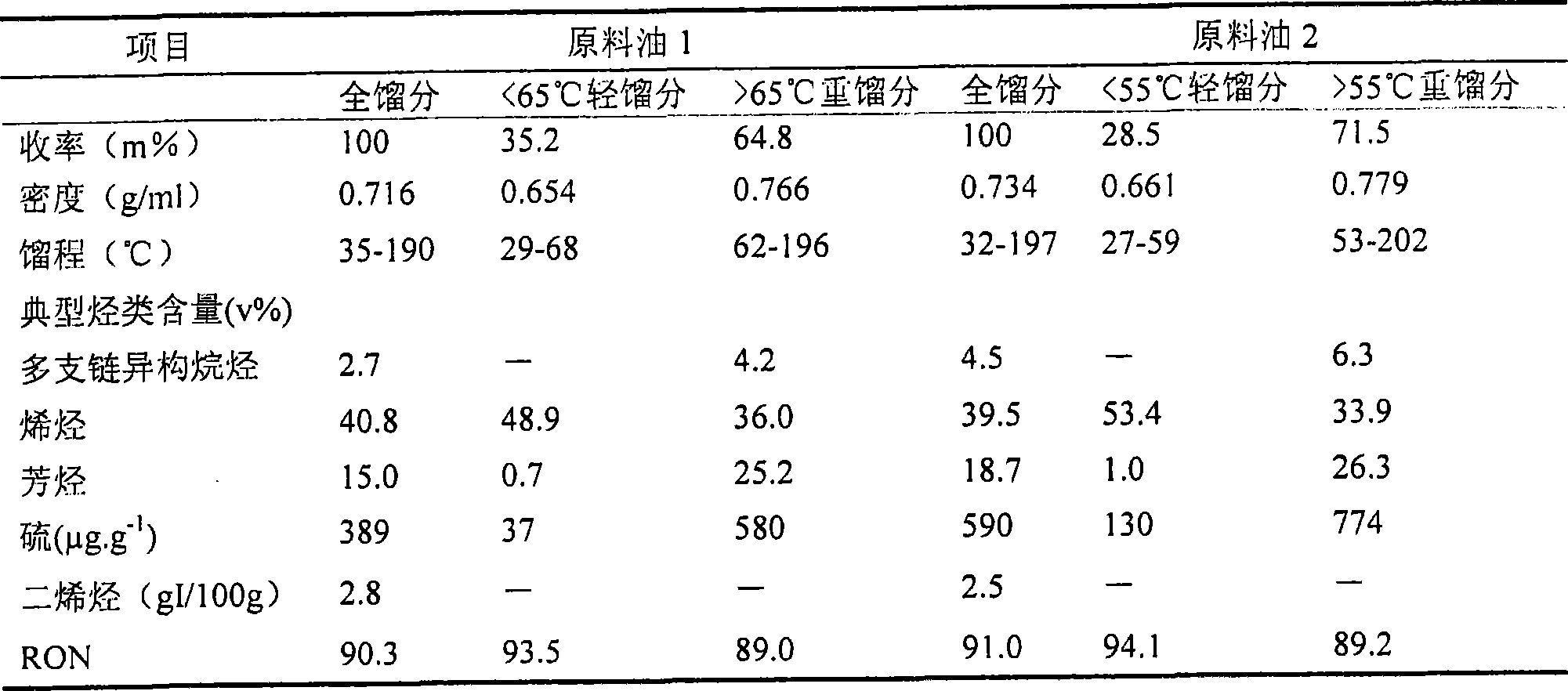

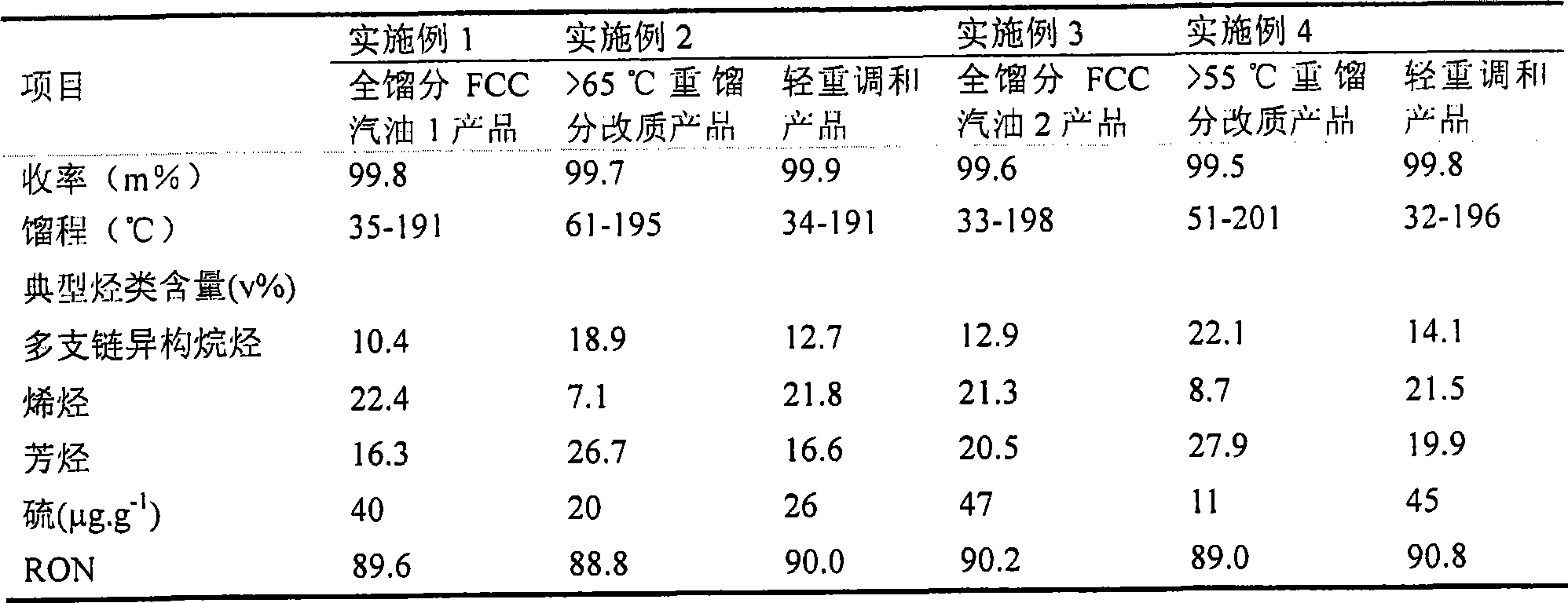

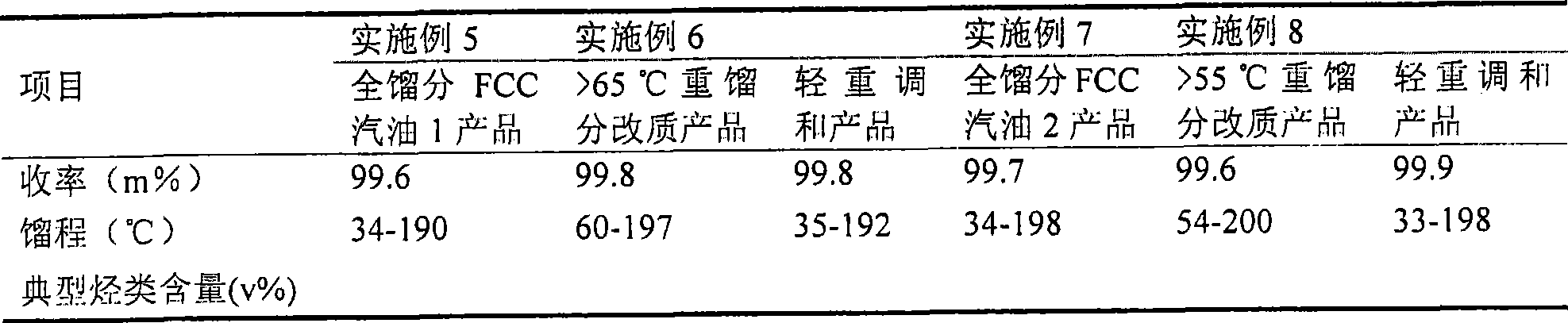

[0054] The difference between this example and Example 1 is that the full fraction FCC gasoline 1 is cut into light and heavy FCC gasoline at 65°C, and their properties are shown in Table 1. Heavy FCC gasoline is used as a reaction raw material for two-stage hydro-upgrading treatment. The catalyst is the same as in Example 1. The raw oil product (heavy fraction) is reacted sequentially through two stages of catalysts, and then the modified heavy gasoline reaction product is mixed with the light gasoline fraction to obtain low-sulfur, low-olefin clean gasoline.

[0055] Among them, the two-stage series reaction conditions of heavy FCC gasoline 1 are as follows: the pressure is 1.5MPa, the volume ratio of hydrogen to oil is 400, the reaction temperature of the first stage is 240°C, and the volume space velocity is 3.0h -1 , the second reaction temperature is 300°C, the volume space velocity is 1.5h -1 .

[0056] The properties of the modified reaction products are shown in Tabl...

Embodiment 3

[0058] The difference between this example and Example 1 is that the raw material oil is changed from full fraction FCC gasoline 1 to full fraction FCC gasoline 2, and the properties of the oil are shown in Table 1.

[0059] The conditions for the two-stage series reaction of full fraction FCC gasoline 2 are as follows: the pressure is 1.8MPa, the volume ratio of hydrogen to oil is 500, the first stage reaction temperature is 230°C, and the volume space velocity is 4.0h -1 , the second reaction temperature is 290℃, the volume space velocity is 2.0h -1 .

[0060] The properties of the modified reaction products are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com