Ripple glaze arch bar, steel bar longeron and concrete combined arch shell structure

A reinforced truss and concrete technology, which is applied to arch structures, dome roof structures, building components, etc., can solve the problems of poor local impact resistance, labor and time-consuming, and elimination, and achieve high local impact resistance. The effect of good overall performance and high overall resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

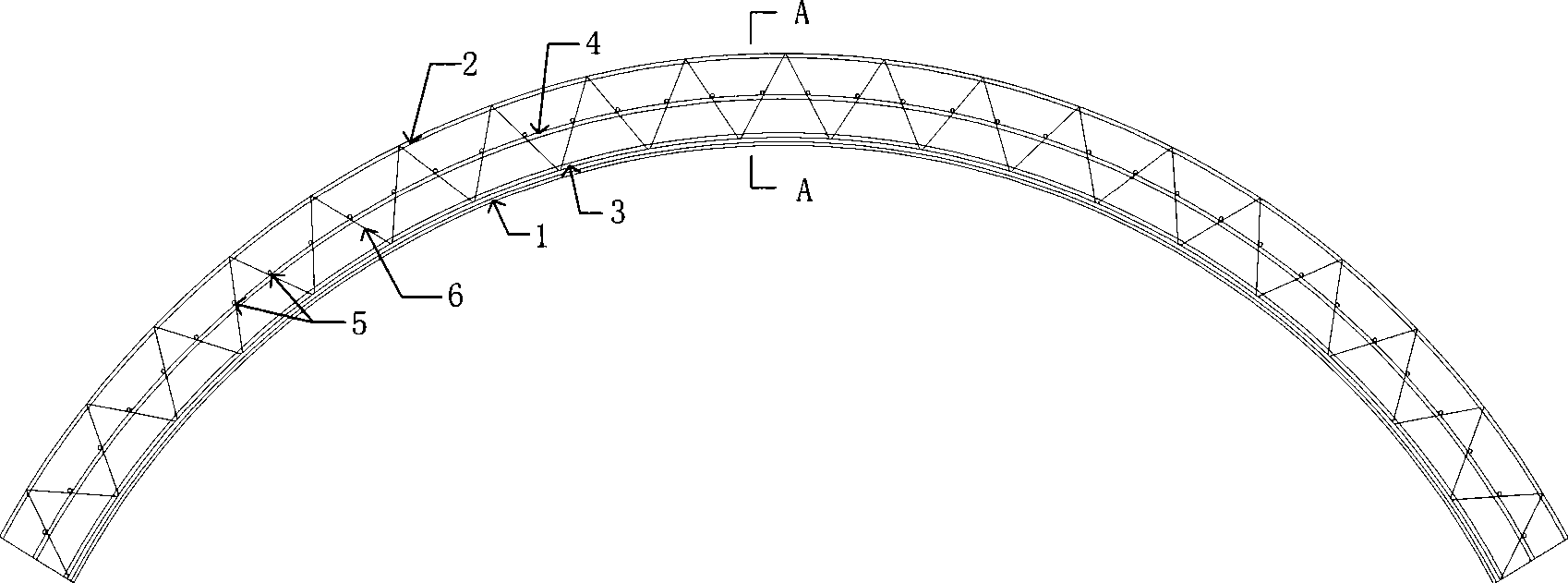

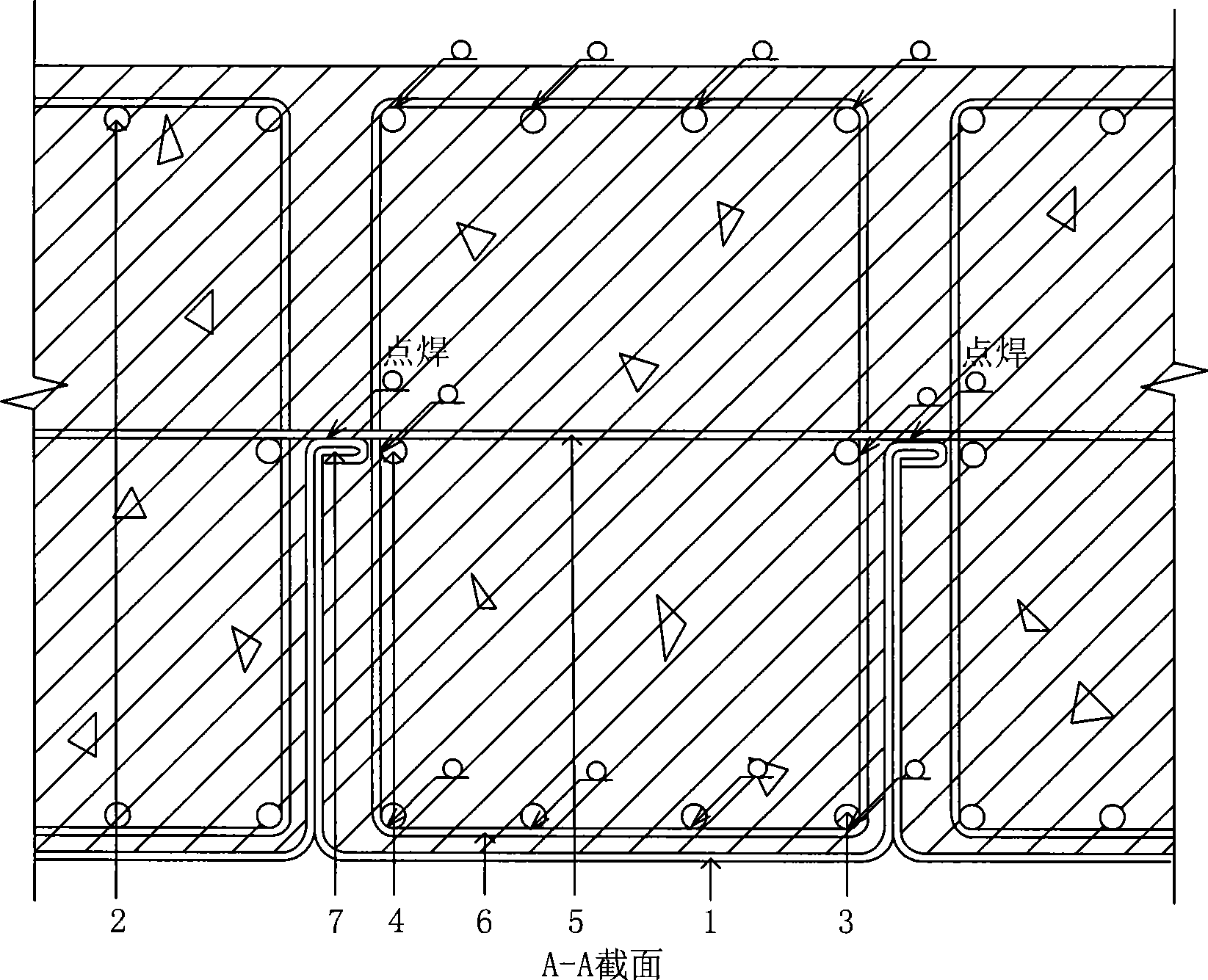

[0013] Such as Figure 1~2 As shown, 1- corrugated arch plate 2- upper chord longitudinal reinforcement 3- lower chord longitudinal reinforcement 4- web reinforcement 5- transverse reinforcement 6- web bar 7- corrugated arch slab undercut.

[0014] The corrugated arch plate, steel bar truss arch and concrete composite arch shell structure of the present invention is composed of corrugated arch plate 1, steel bar truss and concrete. The corrugated arch plate can be combined into an arch shell of any length through the undercut 7, and the upper chord longitudinal rib 2, the lower chord longitudinal rib 3, and the web tendons can form a reinforced truss arch by welding with obliquely placed web bars. The transverse steel bar is welded (or bound) to the steel bar truss arch, and connected by spot welding at the joint 7 of the corrugated arch plate. Therefore, the corru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com