Method for rapidly and reliably coupling emission power of light sending and receiving device and coaxial coupling cramp

An optical transceiver device and coupling coaxial technology, which is applied in the field of coupling fixtures, can solve the problems of high manufacturing cost of large fixtures, unreliable glue pre-fixation, and inability to guarantee coaxiality, etc., so as to ensure the yield rate, save cost investment, simple effect design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with the best embodiment shown in the accompanying drawings, it will be further described in detail.

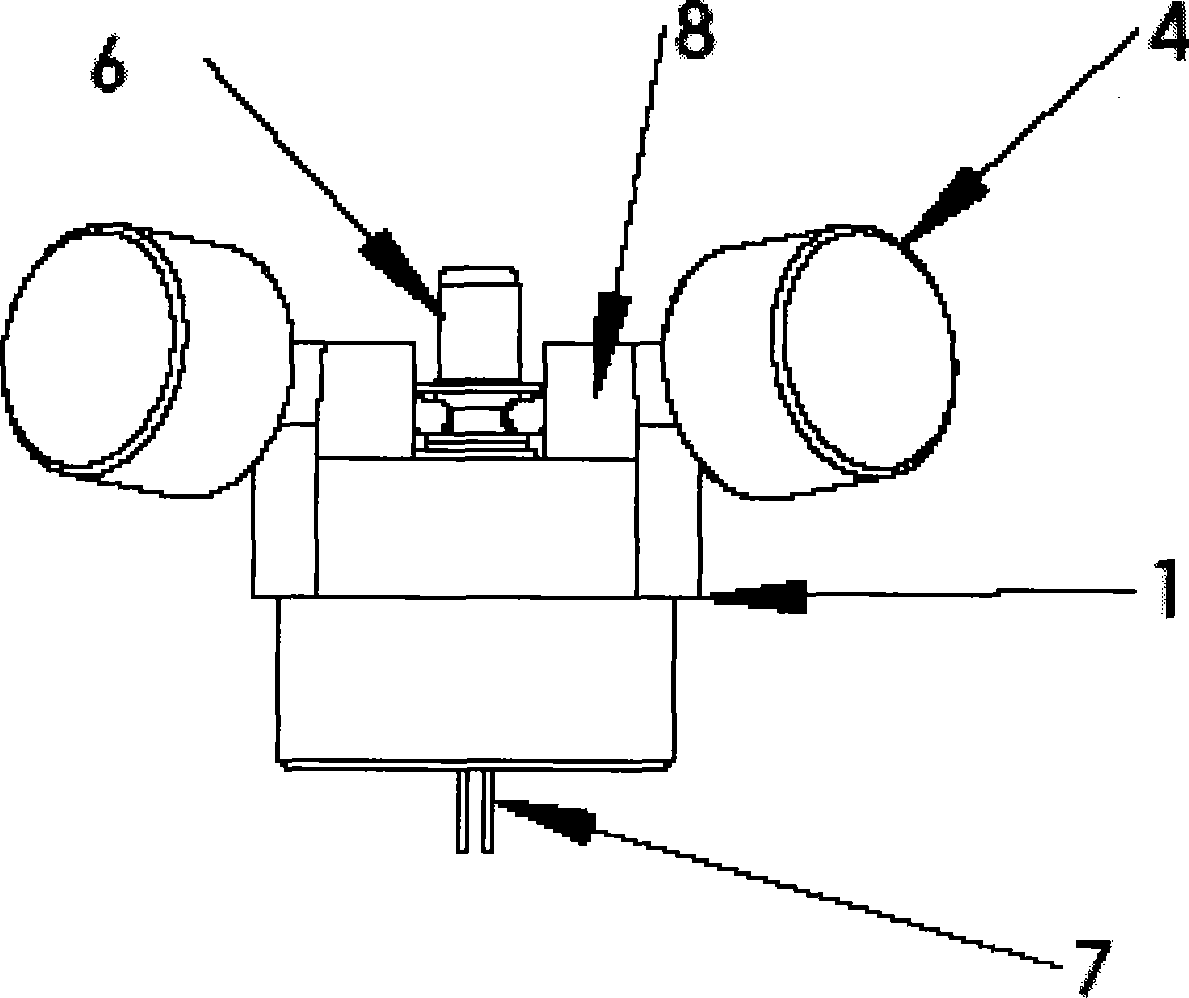

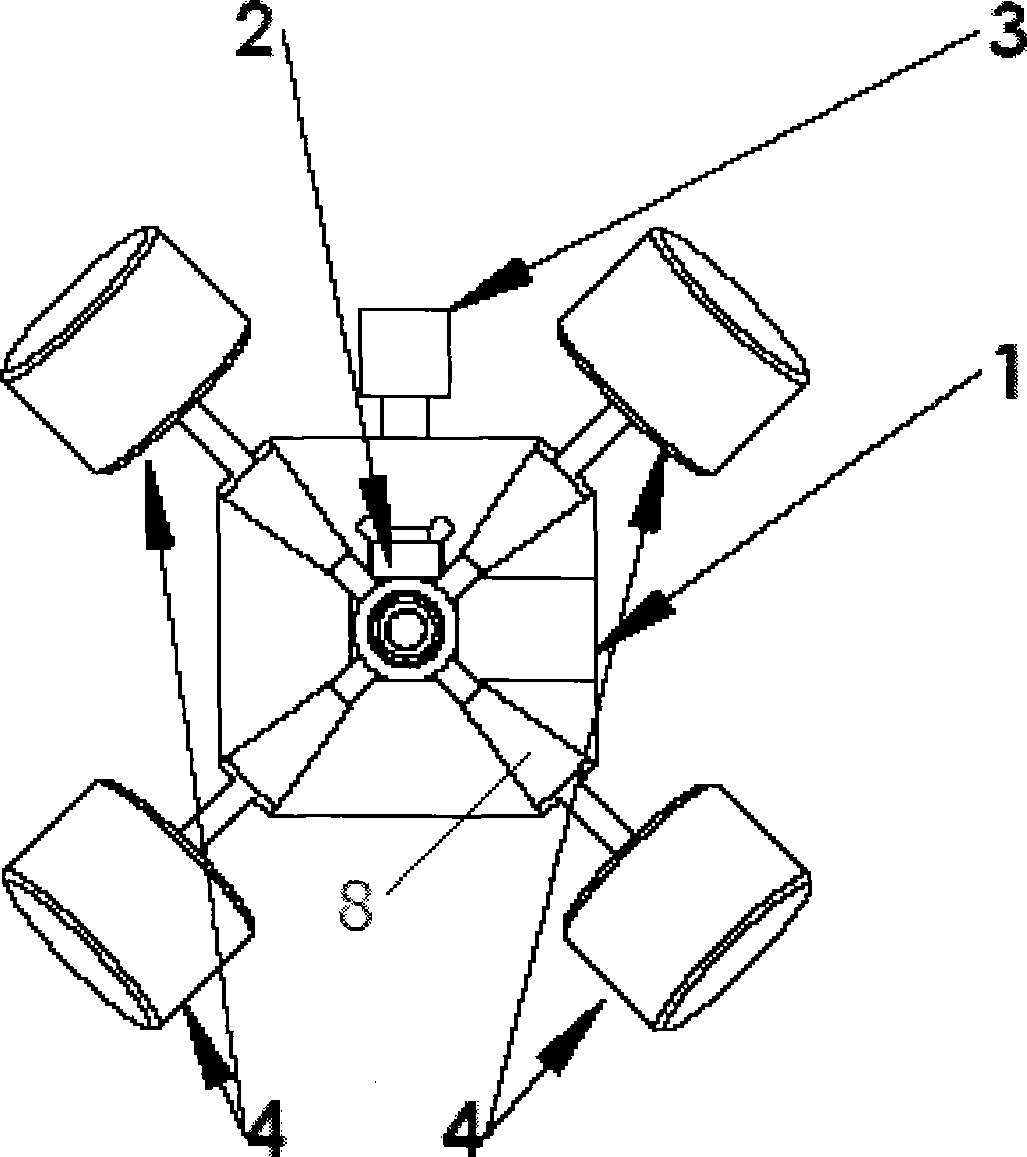

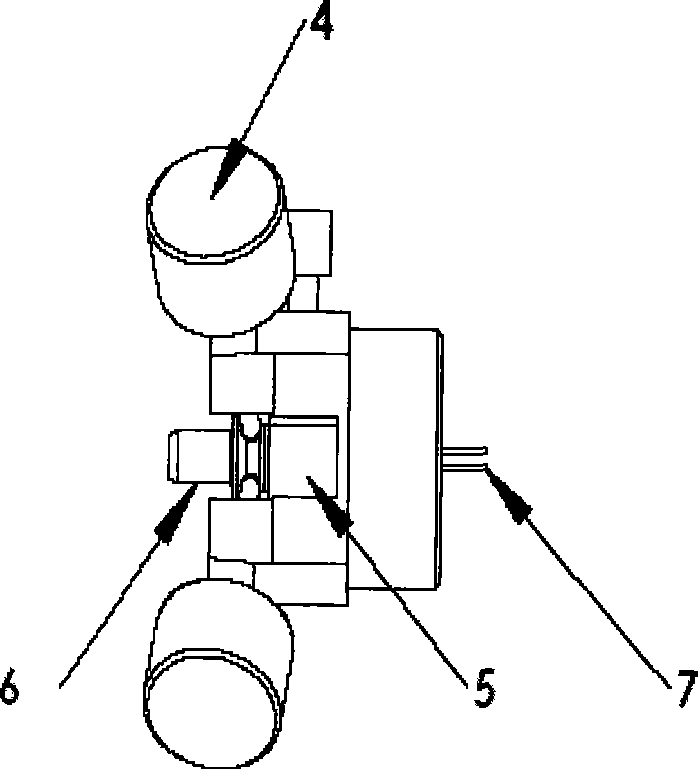

[0017] According to the present invention, a coupling fixture capable of clamping the laser semi-finished product 5 and the optical fiber semi-finished product 6, moving in the X and Y planes and fixing them is prepared. Put the above-mentioned semi-finished laser product 5 to be coupled into the coupling fixture, then put the semi-finished fiber 6 into the corresponding steps of the semi-finished laser, and fix it with four coupling screws. Then transmit power coupling. Through the two opposite screws among the four coupling locking screws 4, the plane movement adjustment in the XY direction is carried out. Start optical power coupling. When the optical power is coupled to the maximum, correspondingly tighten the four coupling screws. Put the coupling fixture and the coupled optical transceiver device into the four-beam laser welding machine fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com