LTCC lamination microstrip patch antenna

A microstrip patch antenna and stacking technology, which is applied to the structural form of antennas, electrical components, and radiating elements, can solve the problems of late start of LTCC antennas, improve stability and reliability, reduce section thickness, and enhance coupling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

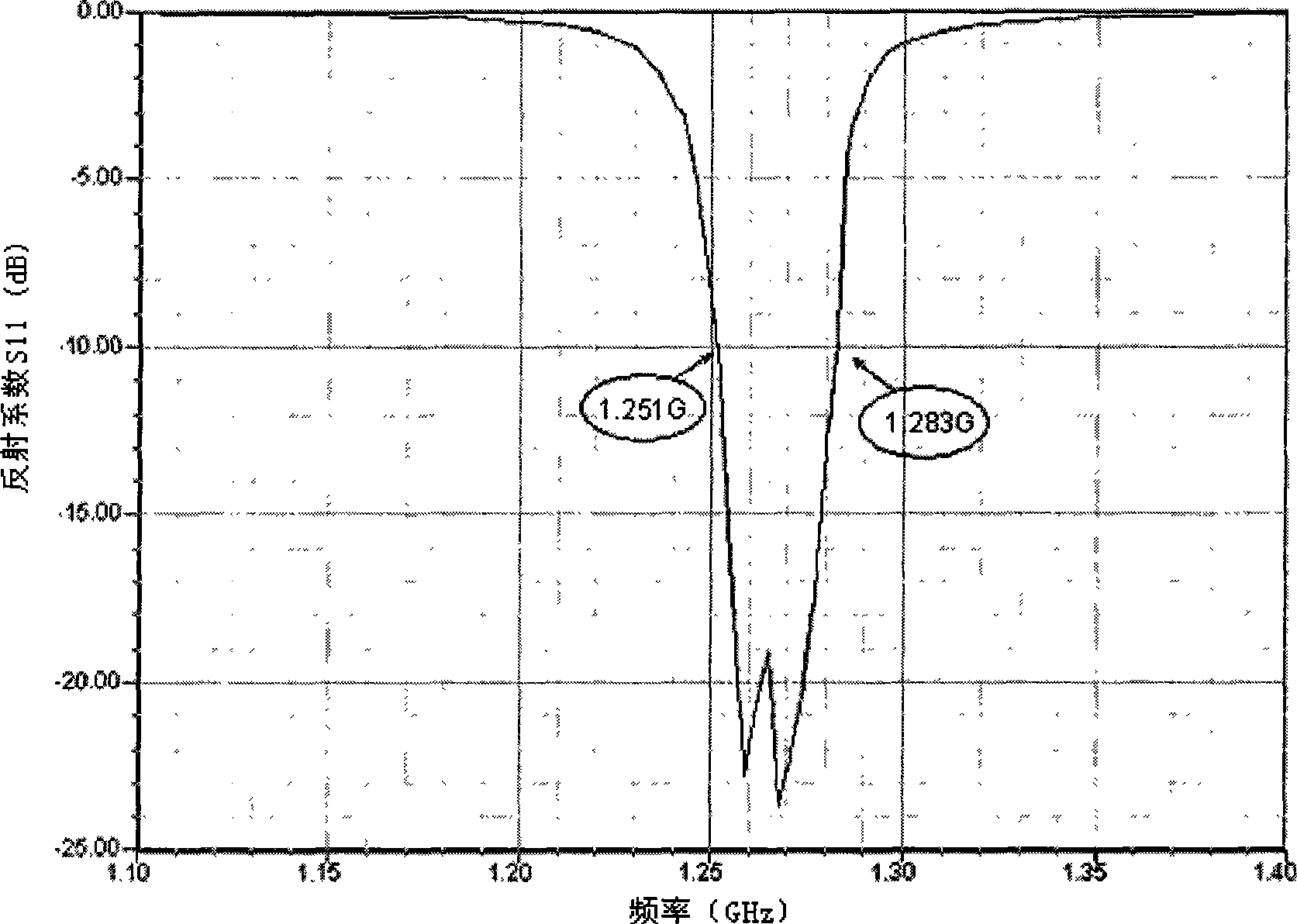

[0022] The center frequency of the microstrip patch antenna in the preferred embodiment is 1.268GHz, and it is a BD-2 microstrip receiving antenna. The present invention can realize a microstrip patch antenna with an impedance bandwidth exceeding 30MHz within a section thickness of 2.5mm.

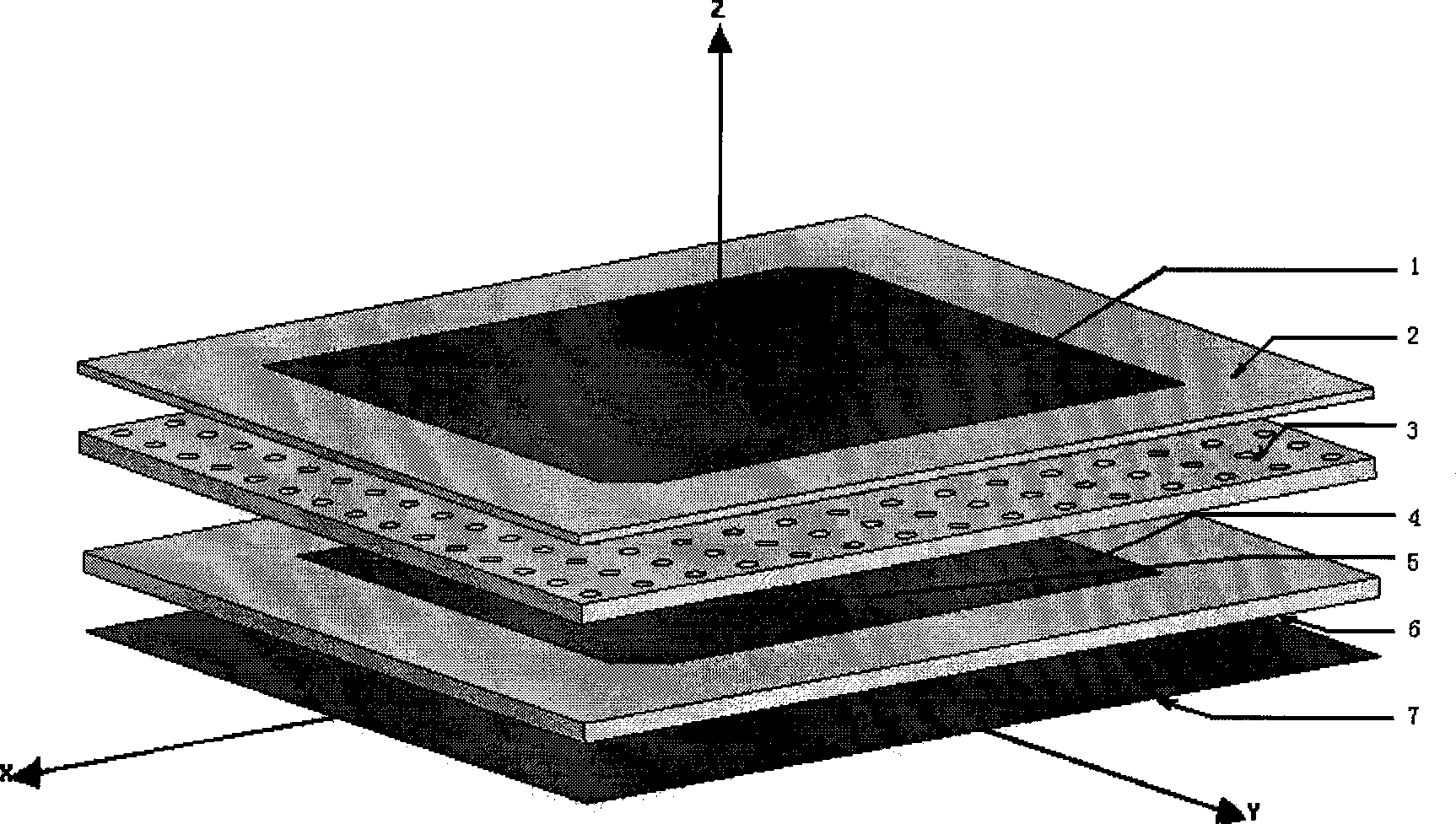

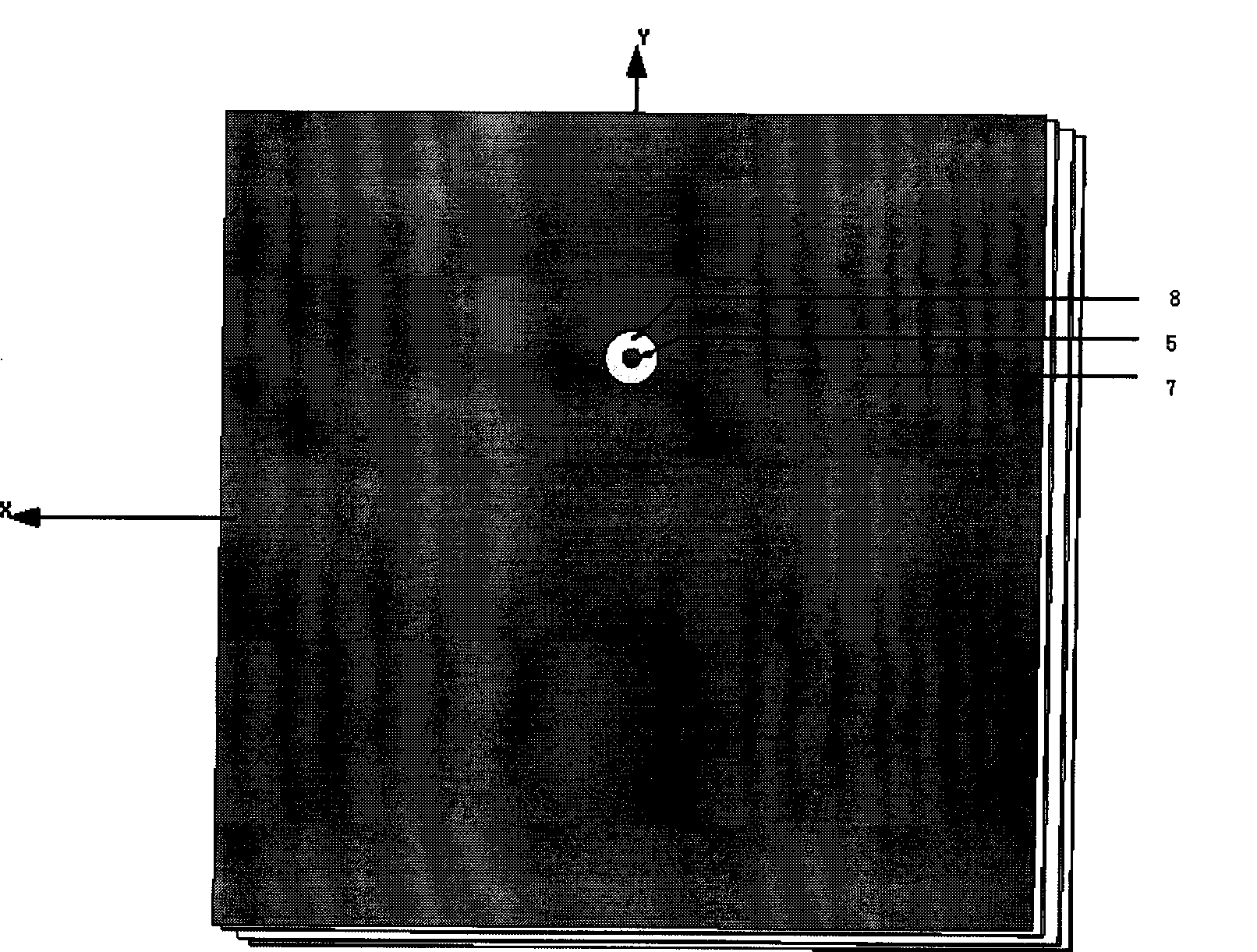

[0023] figure 1 and figure 2 The three-dimensional structural schematic diagram and the bottom view of the LTCC stacked microstrip patch antenna are respectively. The main structures include:

[0024] The first layer of LTCC substrate: It is formed by stacking 10 cast film sheets with a thickness of 0.1mm, and a feed hole with a diameter of about 1mm is opened at an appropriate position on the substrate. The size of the substrate and the position of the feed hole need to be determined by simulating a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com