Control method for electron beam punching machine acceleration high-voltage power supply and power supply device

A high-voltage power supply and control method technology, applied in emergency protection circuit devices, output power conversion devices, electrical components, etc., can solve the problems of large inertia and slow adjustment speed of the control system, and achieve small size and power consumption. Small, small energy storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

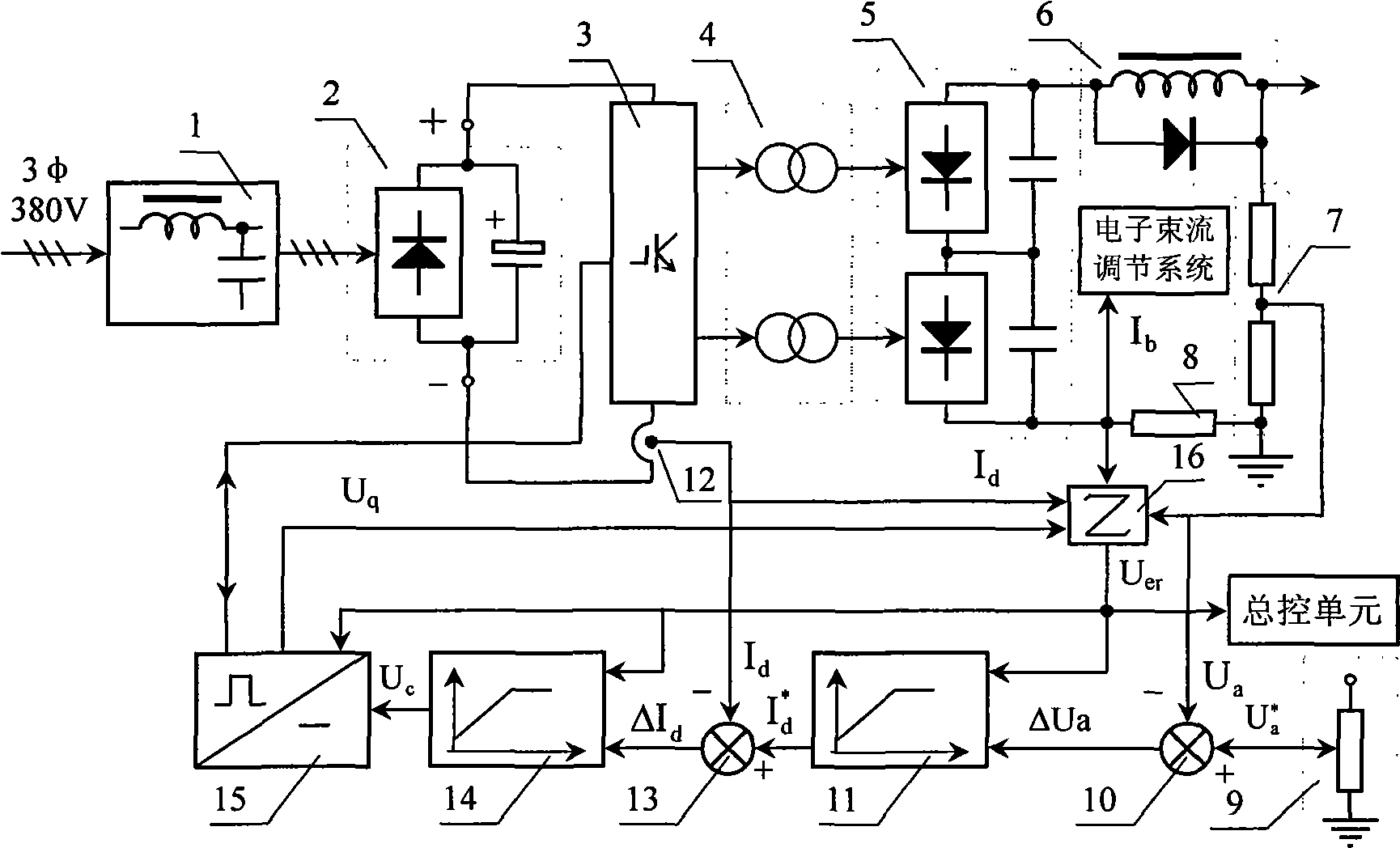

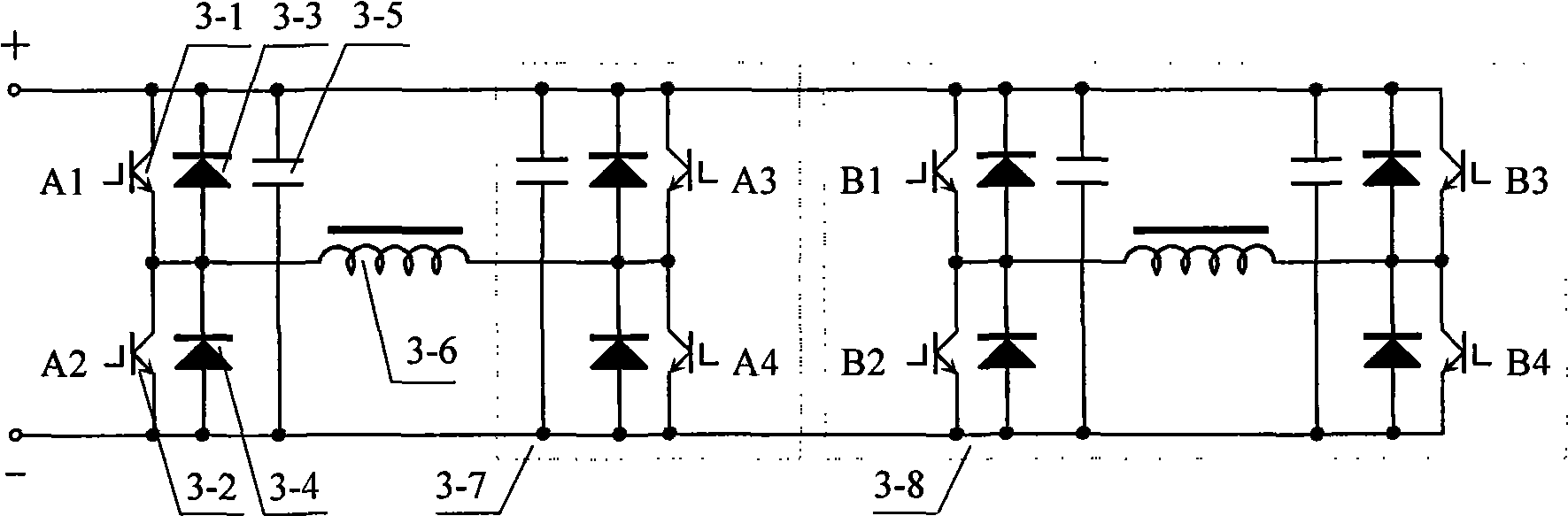

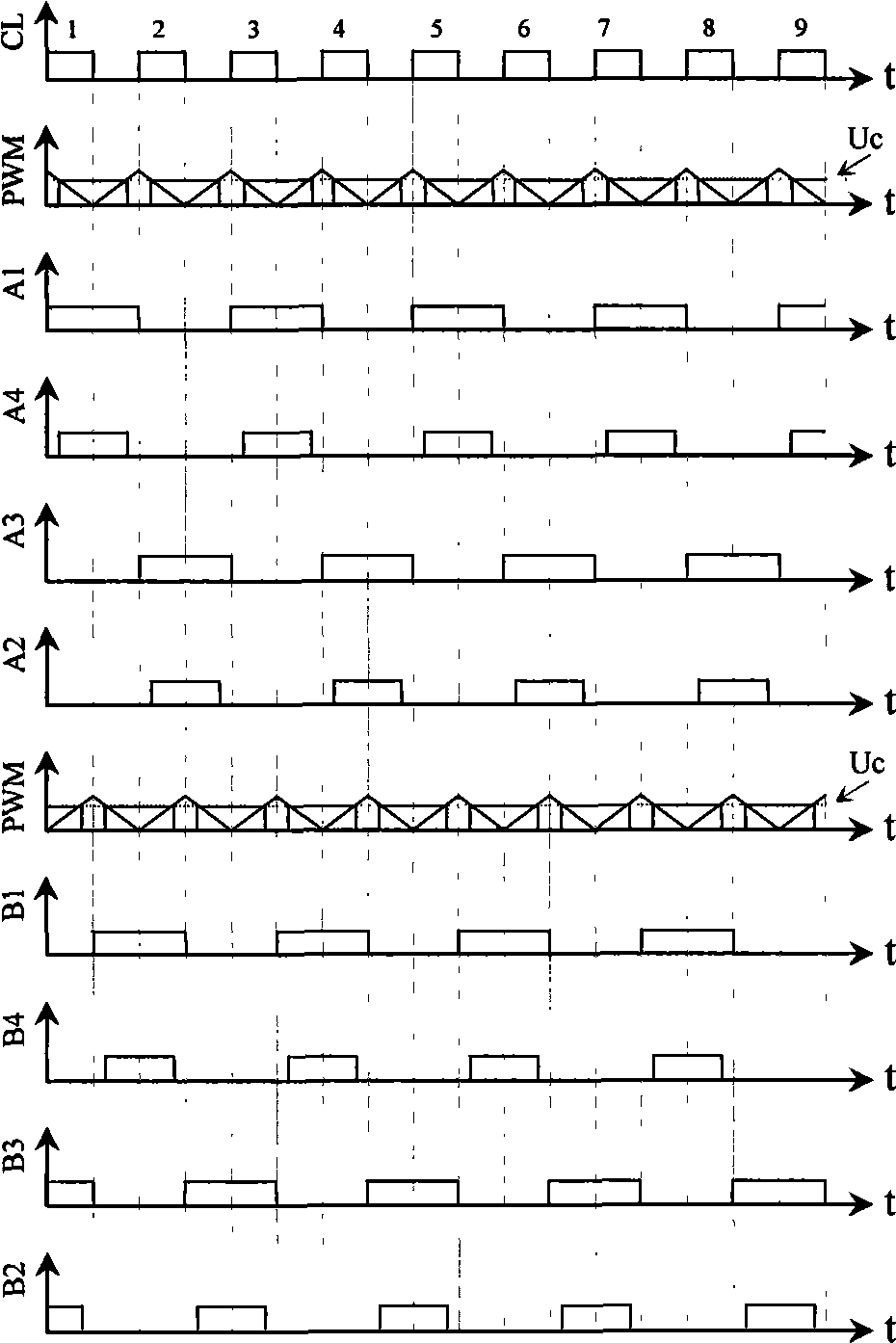

[0023] The control method for accelerating the high-voltage power supply of the electron beam drilling machine of the present invention, the power supply is powered by three-phase commercial power, and adopts the AC→DC→AC→DC current conversion mode, that is, the power supply adopts industrial frequency AC input→low voltage rectification and filtering→high frequency inverter Variable and pulse width modulation voltage regulation → high frequency transformer boost → high voltage rectification and filtering current conversion mode output. The intermediate DC→AC inverter link is high-frequency inverter, which realizes the function of high-frequency pulse width modulation and voltage regulation at the same time during the inverter process; the high-frequency high-voltage transformer realizes the transmission of electric energy, the transformation of voltage value and high-voltage insulation; accelerates the adoption of high-voltage power supply The double closed-loop control method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com