Multi-level and multi-direction Y-type impinging jet mixer

A technology of mixers and jets, which is applied in the direction of fluid mixers, mixers, mixing methods, etc., can solve the problems of lowering TPC temperature, uneven polymerization degree of monomers, and TPC solidification, so as to avoid condensation, ensure continuity and Stable, easy-to-set effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

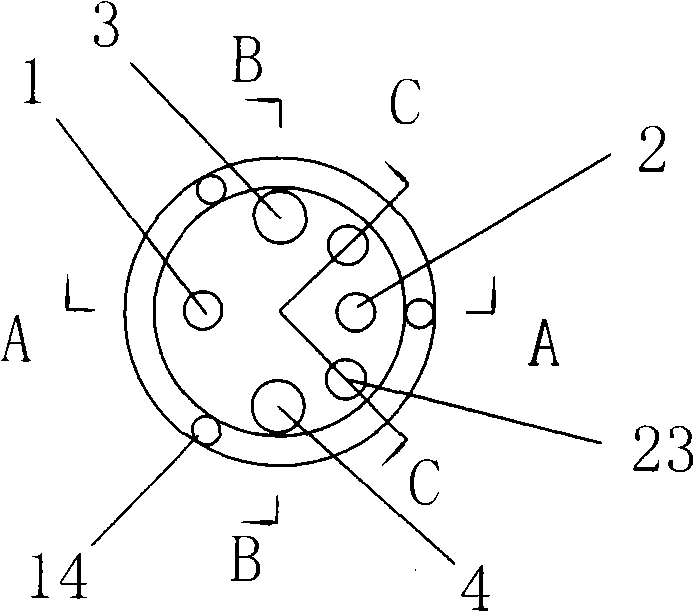

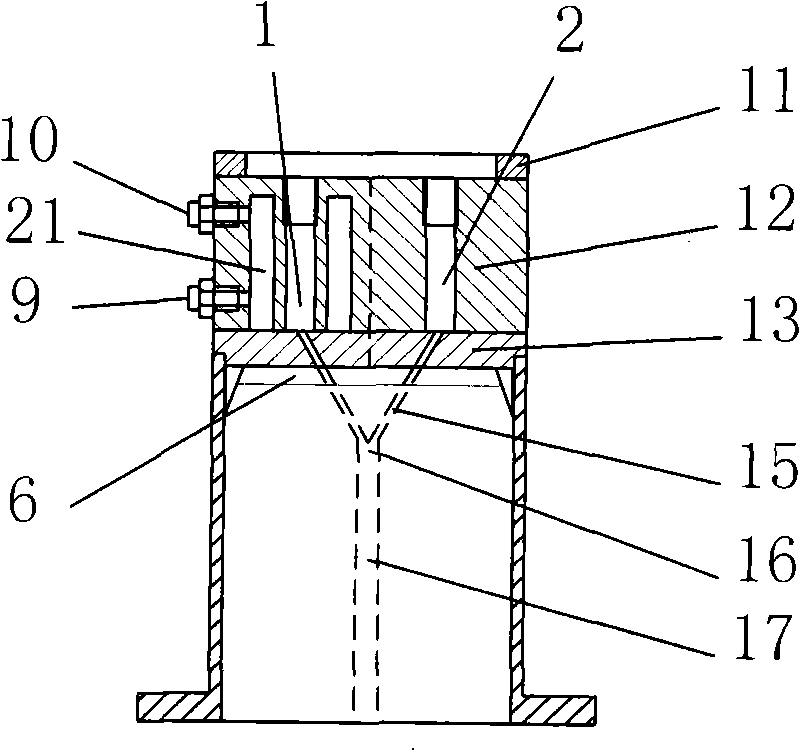

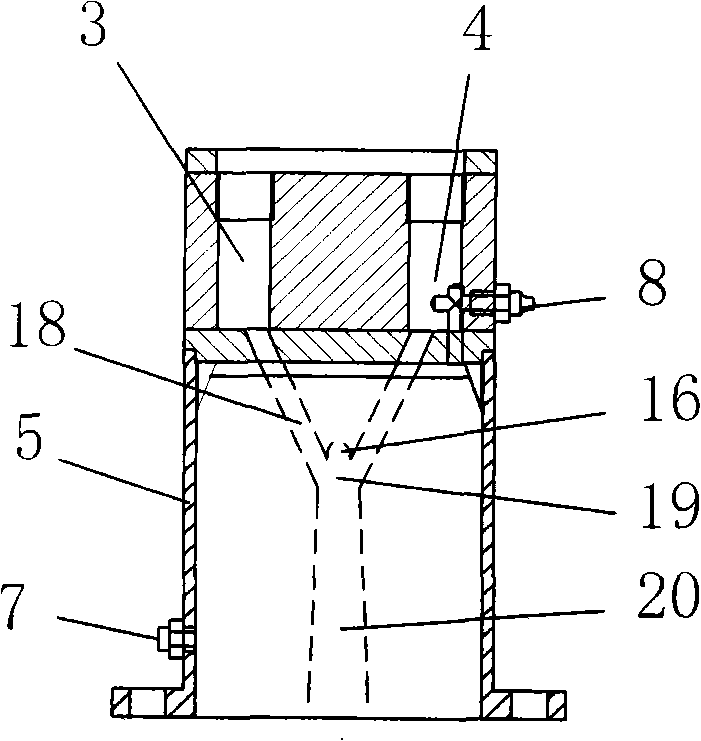

[0024] see Figure 1-6 , the present invention provides a multi-stage, multi-directional Y-type jet impact mixer, which is provided with multi-stage jet channels, and an acute angle is formed between the jets 15 or 18 of each jet channel of the same level (wherein 15 is two first-level Jet, 18 is two secondary jets), and intersects in the same impact area 16 or 19 of this level jet (wherein 16 is the impact area of the first-level jet, and 19 is the impact area of the second-level jet), after each level of jet impact The path of the formed mixed flow 17 or 20 is located on the same straight line (wherein 17 is the mixed flow of the primary jet, and 20 is the secondary jet mixed flow comprising the primary jet mixed flow), and the impact areas of different jets are on the straight line Alternate, contiguous or overlapping distribution, the distribution of the impact areas of the jets at all levels can be the same or different, that is, they can be all intersecting, or all c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com