Method for manufacturing LED chip substrate structure

A technology of light-emitting diode and substrate structure, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of photoresist can not reflow convex hull-shaped microstructure, can not manufacture substrates, hinder the luminous efficiency of chips, etc., to reduce the Interfacial reflections, improved defects, reduced absorption loss effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

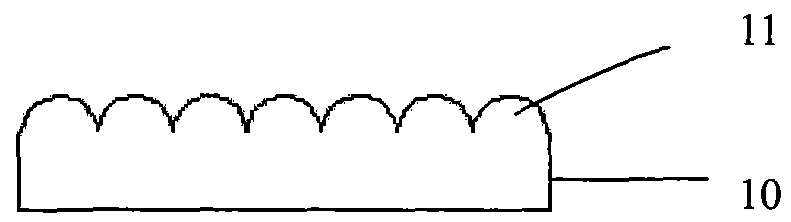

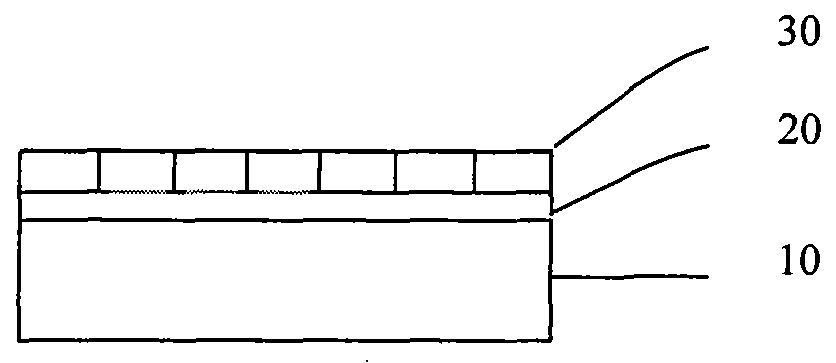

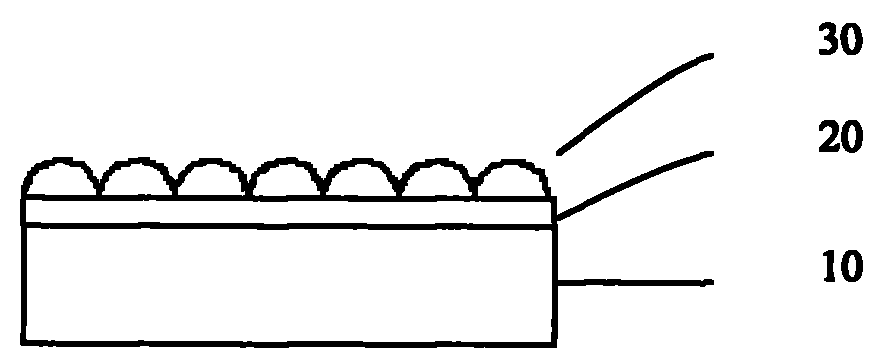

[0027] First refer to Figure 1a As shown, a metal layer 20 is deposited on the sapphire substrate 10 by using an electron beam evaporation machine, the material of the metal layer 20 is titanium, and the thickness is 0.1 nm. Apply photoresist on the metal layer 20 to form a photoresist layer 30, the thickness of the photoresist layer 30 is 0.5um such as Figure 1b shown. Then, the photoresist is patterned on the substrate by a photolithography process to form a desired pattern such as Figure 1c As shown, the pattern is a periodic regular arrangement of cones. Then, the photoresist film layer 30 is reflowed on the metal layer 20 by platform baking photoresist reflow technology, and the photoresist pattern is formed similar to Figure 1d Multiple convex-hull microstructure patterns are shown. The reflux condition is as follows: the baking temperature is 50° C., and the baking time is 0.1 minute. This pattern is then transferred to sapphire using ICP (Inductively Coupled P...

Embodiment 2

[0030] First refer to Figure 1a As shown, a metal layer 20 is plated on the sapphire substrate 10 by using an electron beam evaporation machine, the material of the metal layer 20 is nickel, and the thickness is 20nm. Coat photoresist on this metal layer 20, form one deck photoresist film layer 30, the thickness of photoresist film layer 30 is 2um such as Figure 1b shown. Then, the photoresist is patterned on the substrate by a photolithography process to form a desired pattern such as Figure 1c As shown, the pattern is a periodic regular arrangement of quadrangular prisms. Then, the photoresist film layer 30 is reflowed on the metal layer 20 by platform baking photoresist reflow technology, and the photoresist pattern is formed similar to Figure 1d Multiple convex-hull microstructure patterns are shown. The reflow conditions are as follows: the baking temperature is 200° C., and the baking time is 20 minutes. This pattern is then transferred to sapphire using ICP (In...

Embodiment 3

[0033] First refer to Figure 1a As shown, a metal layer 20 is deposited on a sapphire substrate 10 by using an electron beam evaporation machine, the material of the metal layer 20 is aluminum, and the thickness is 50nm. Coat photoresist on this metal layer 20, form one deck photoresist film layer 30, the thickness of photoresist film layer 30 is 4um such as Figure 1b shown. Then, the photoresist is patterned on the substrate by a photolithography process to form a desired pattern such as Figure 1c As shown, the pattern is a non-periodic regular arrangement of circular frustums. Then, the photoresist film layer 30 is reflowed on the metal layer 20 by platform baking photoresist reflow technology, and the photoresist pattern is formed similar to Figure 1d Multiple convex-hull microstructure patterns are shown. The reflow conditions are as follows: the baking temperature is 400° C., and the baking time is 60 minutes. This pattern is then transferred to sapphire using IC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com