Method for producing a temperature measuring sensor

一种温度传感器、导线的技术,应用在温度计的零部件、温度计、用直接对热敏感的电/磁性元件的温度计等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

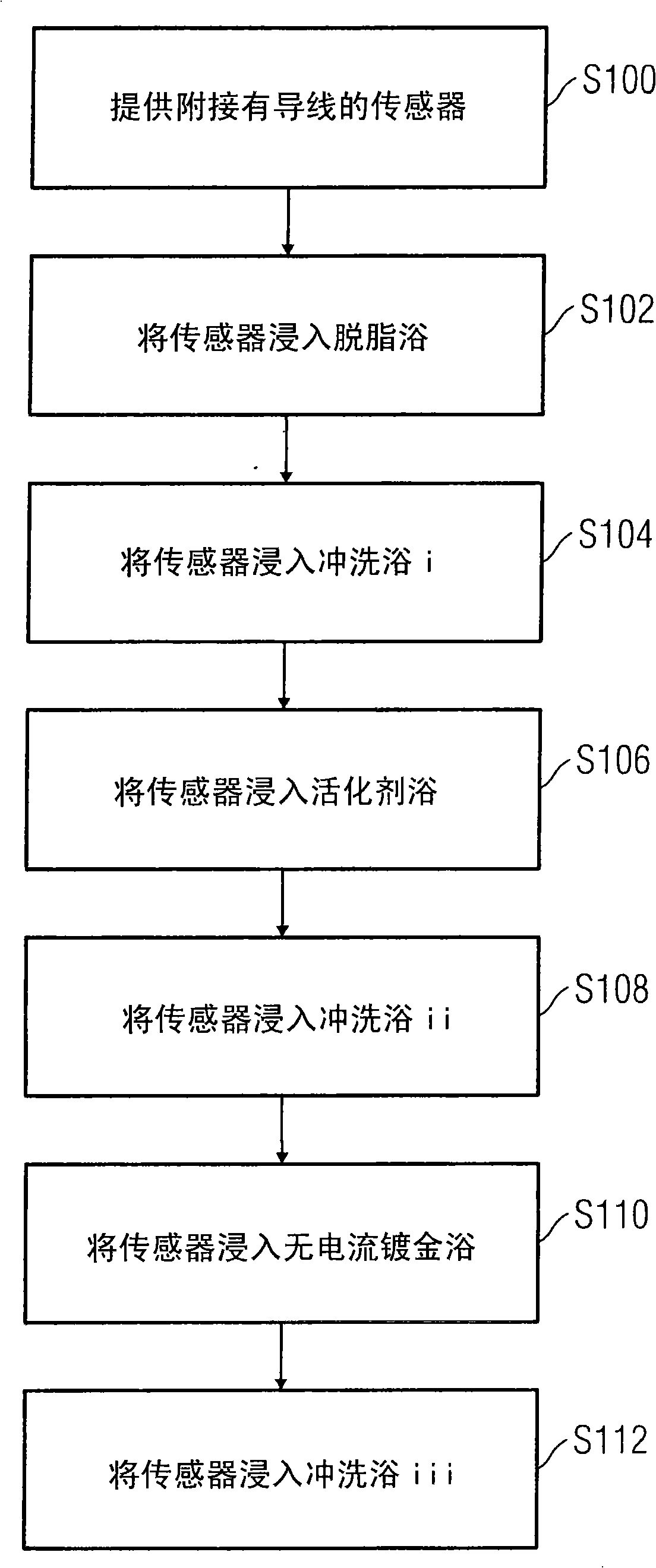

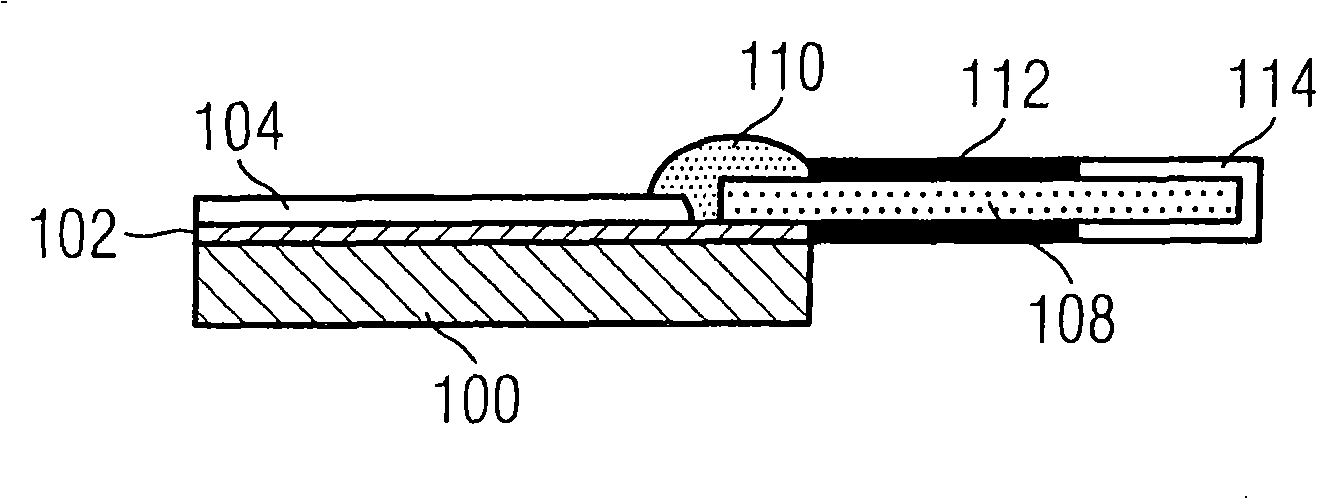

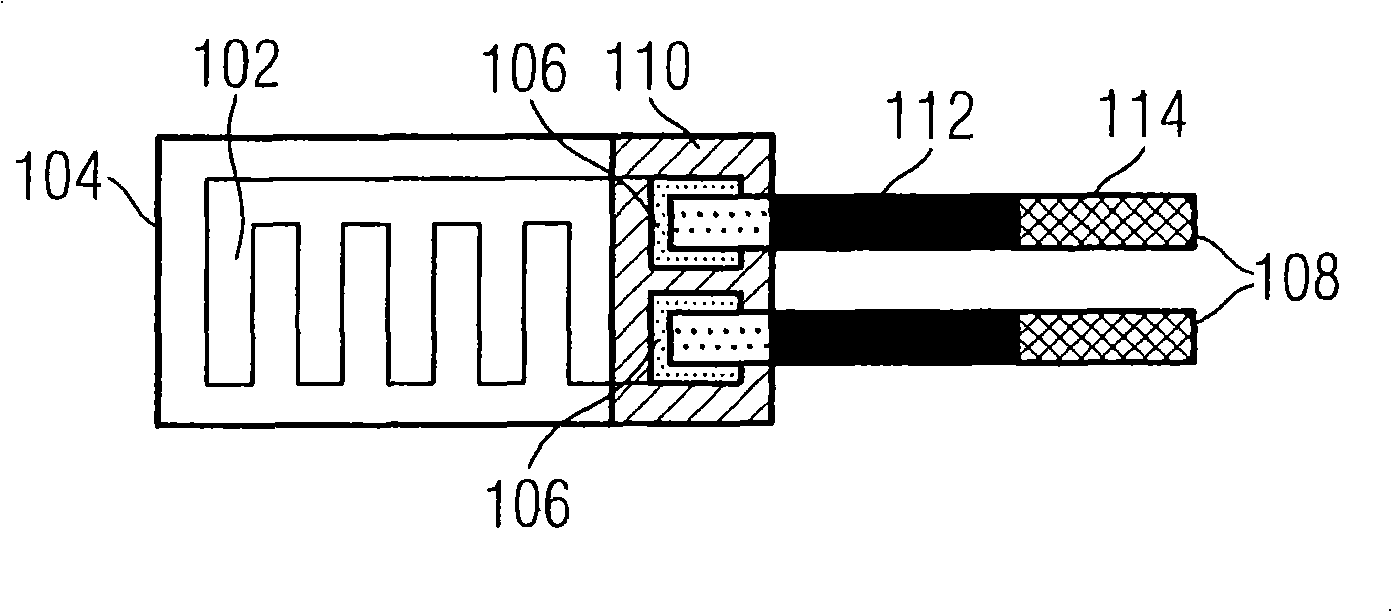

[0032] now according to figure 1 , a preferred embodiment of the manufacturing method according to the present invention will be explained in more detail. As shown in step S100 , assuming the temperature sensor as described in FIG. 3 , the wire 108 of the temperature sensor is partially subjected to a reduction process to at least partially remove the oxide layer 112 . In step S102, the sensor is first immersed in the degreasing bath, and then in step S104, the sensor is immersed in the rinse bath I. After rinsing or cleaning, the sensor is immersed in the activator bath in step S106, and then in the rinse bath II in step S108. Then, the sensor is immersed in a currentless gold plating bath in step S110, followed by immersing the sensor in rinse bath III in step S112.

[0033]After step S112 , as shown in FIG. 2 , the sensor has at least partially gold-plated wires. In FIG. 2 , elements already described with reference to FIG. 3 have the same reference numerals. As mention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com