Novel stiffening cloth and processing method thereof

A processing method and a new technology, applied in the direction of heating/cooling fabrics, textiles, clothing, etc., can solve problems affecting human health, consume large energy, and garments are easily deformed, and achieve stable dimensions, improved quality, and good stiffening effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

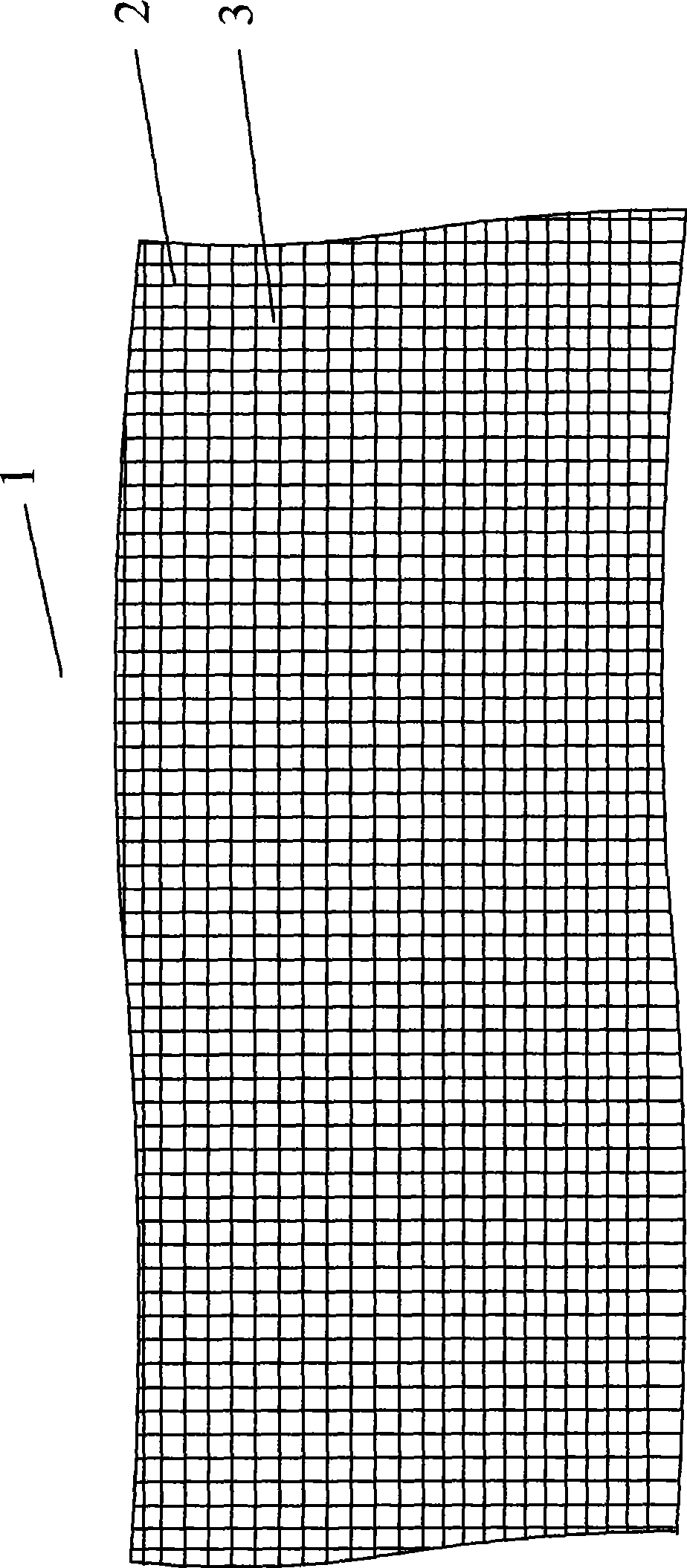

Image

Examples

Embodiment 1

[0032] The low-temperature polyester staple fiber with a yarn content of 2% of the cloth and at least one fiber or multiple fibers are arranged in the order of warp and weft weaving or weaving and then blended into yarns, and then the blended yarns are processed by textile equipment Weaving into cloth, and then through high-temperature setting equipment to heat or heat-setting the textile unshaped cloth, the low-temperature polyester staple fiber is melted at high temperature to form a bonding medium, so that the warp and weft interweaving points of at least one fiber or multiple fibers are bonded. connected together. Among them, the blanching or heat setting temperature of the unshaped cloth in the high temperature setting equipment is 105°C, and the blanching or heat setting time of the semi-finished cloth in the high temperature setting equipment is 0.10 seconds. After the cloth is processed by the above method, not only the tensile strength of the cloth body is increased t...

Embodiment 2

[0034] The low-temperature polyester staple fiber, which accounts for 50% of the cloth yarn content, and at least one fiber or multiple fibers are arranged in the order of warp and weft weaving or weaving, and then blended into yarn, and then the blended yarn is processed by textile equipment. Weaving into cloth, and then through high-temperature setting equipment to heat or heat-setting the textile unshaped cloth, the low-temperature polyester staple fiber is melted at high temperature to form a bonding medium, so that the warp and weft interweaving points of at least one fiber or multiple fibers are bonded. connected together. Among them, the blanching or heat setting temperature of the unshaped cloth in the high temperature setting equipment is 100°C, and the blanching or heat setting time of the semi-finished cloth in the high temperature setting equipment is 100 seconds. After the cloth is processed by the above method, not only the tensile strength of the cloth body is i...

Embodiment 3

[0036] The low-temperature polyester staple fiber, which accounts for 90% of the yarn content of the cloth, and at least one fiber or multiple fibers are arranged in the order of warp and weft weaving or weaving, and then blended into yarn, and then the blended yarn is processed by textile equipment. Weaving into cloth, and then through high-temperature setting equipment to heat or heat-setting the textile unshaped cloth, the low-temperature polyester staple fiber is melted at high temperature to form a bonding medium, so that the warp and weft interweaving points of at least one fiber or multiple fibers are bonded. connected together. Among them, the blanching or heat setting temperature of the unshaped cloth in the high temperature setting equipment is 215°C, and the blanching or heat setting time of the semi-finished cloth in the high temperature setting equipment is 120 seconds. After the cloth is processed by the above method, not only the tensile strength of the cloth bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com