Method for preparing iminodiacetic acid

A technology of iminodiacetic acid and iminodiacetonitrile, which is applied in the field of preparation of iminodiacetic acid, can solve problems such as not having the value of mass production in factories, achieve significant production capacity advantages, reduce labor costs, and reduce labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

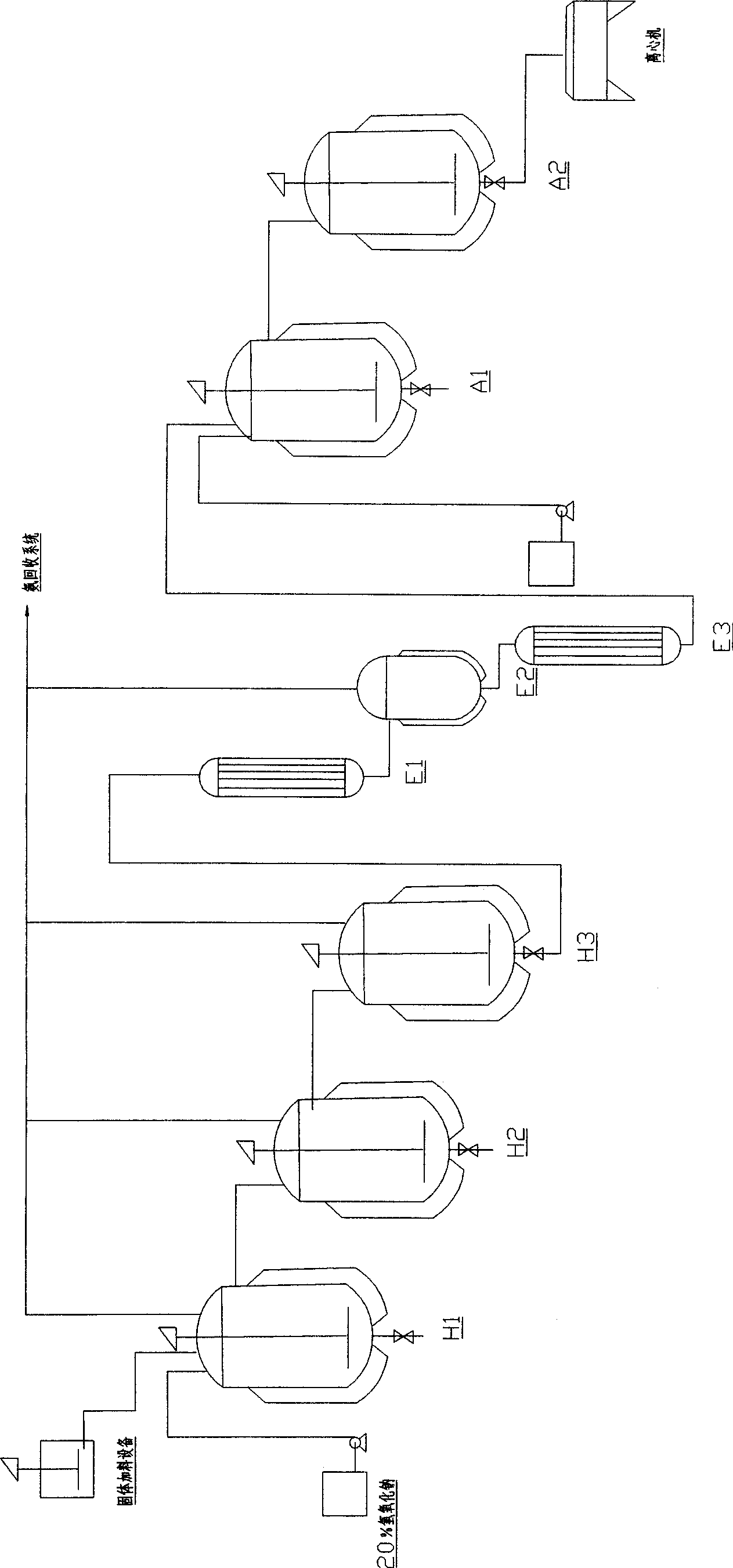

[0025] Such as figure 1 Shown, a kind of method for preparing iminodiacetic acid, this method comprises the following steps:

[0026] Iminodiacetonitrile (95%) feed rate: 93kg / h, add in the first hydrolysis kettle H1 with adjustable speed feeder, dropwise add 20% sodium hydroxide simultaneously, drop rate 390kg / h, iminodiacetonitrile The molar ratio to sodium hydroxide is 1:2.1, and the temperature is controlled at 40-50°C. As the reaction progresses, the reaction liquid naturally flows into the second hydrolysis kettle H2 and the third hydrolysis kettle H3. The total retention time in the three hydrolysis kettles H1, the second hydrolysis kettle H2, and the third hydrolysis kettle H3 is 1h, and then the reaction liquid is heated to 105°C with the heat exchanger E1, and then enters the gas-liquid separation tank E2 for gas Liquid separation and ammonia removal at the same time, about 10% of the total weight of water vapor and ammonia will enter the ammonia recovery system, an...

Embodiment 2

[0028] see figure 1 Shown, a kind of method for preparing iminodiacetic acid, the mol ratio of iminodiacetonitrile and sodium hydroxide is 1:2.3 in this method, other adopts the processing step identical with embodiment 1, and hydrolysis yield is 103%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com