Method for preparing high saturation magnetisation CoFe alloy powder by using hydrotalcite as single precursor

A technology of magnetization and hydrotalcite, applied in the direction of magnetic objects, magnetic materials, circuits, etc., can solve the problems of complex preparation process, uneven diffusion, and environmental hazards of CoFe polymer precursors, so as to avoid diversification of metal sources and crystallization. The effect of complete particle structure and precise chemical ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

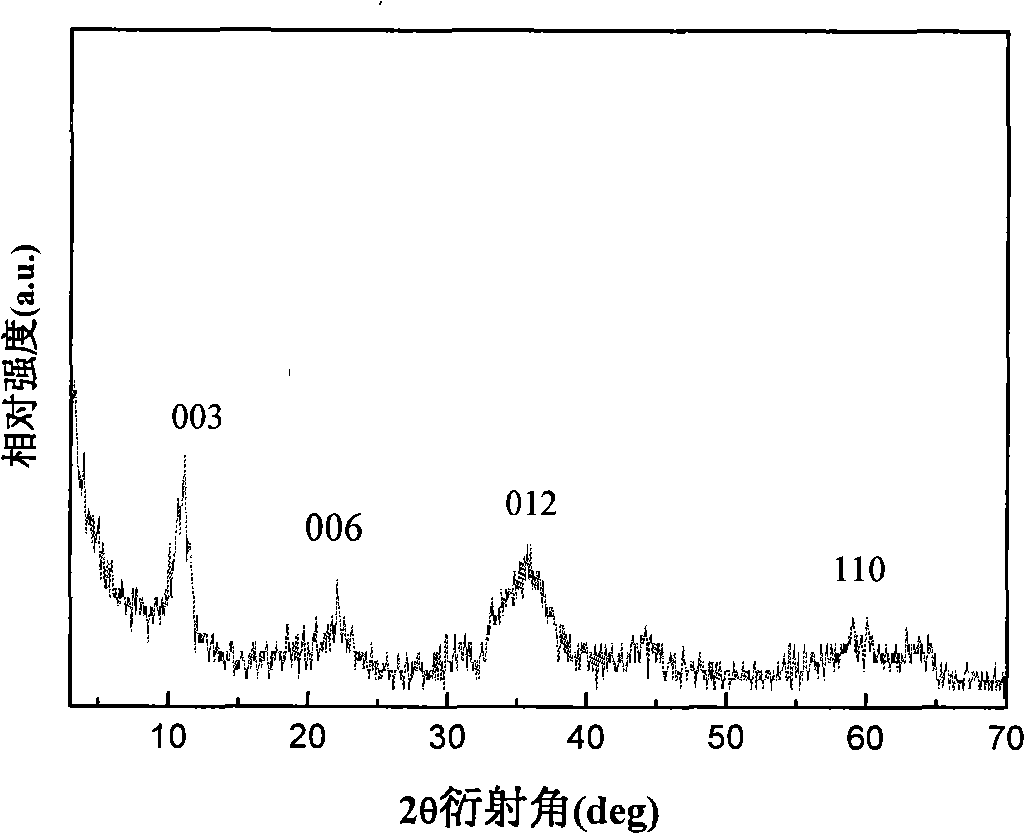

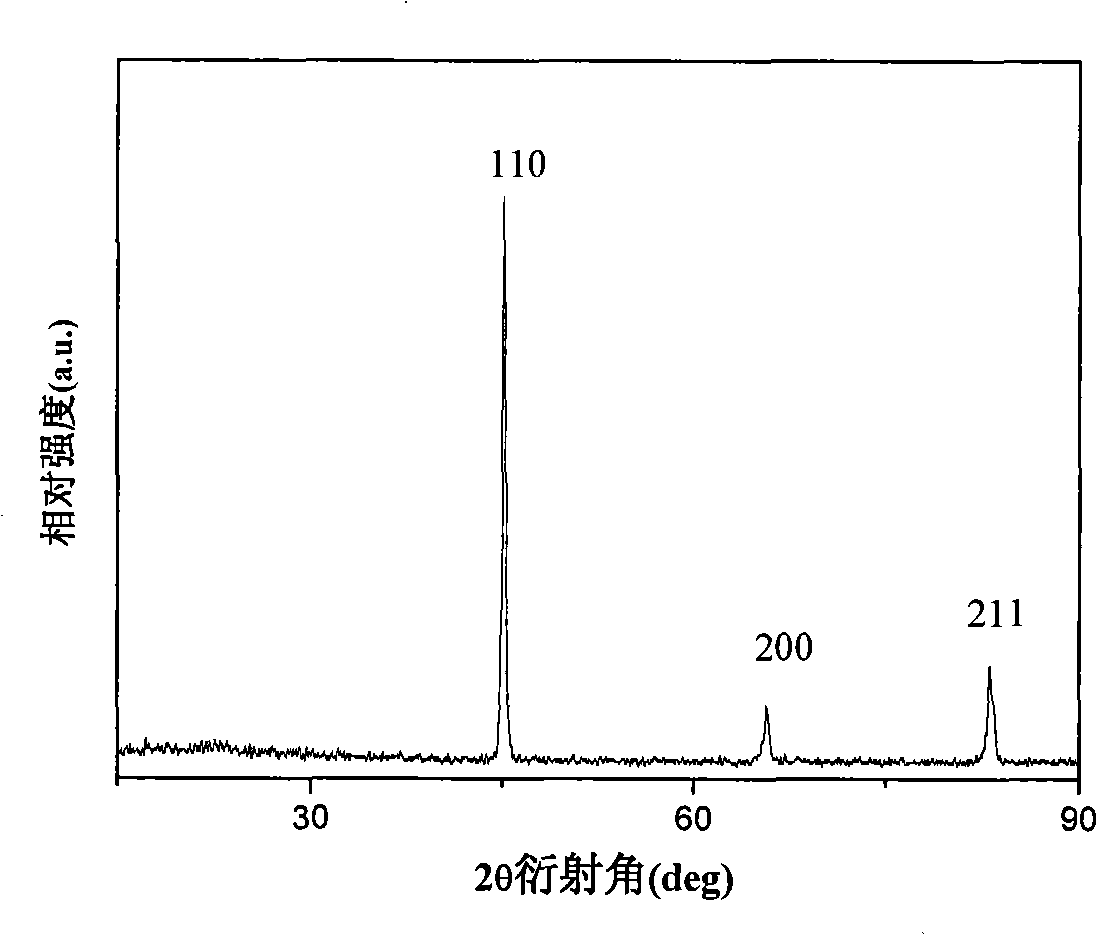

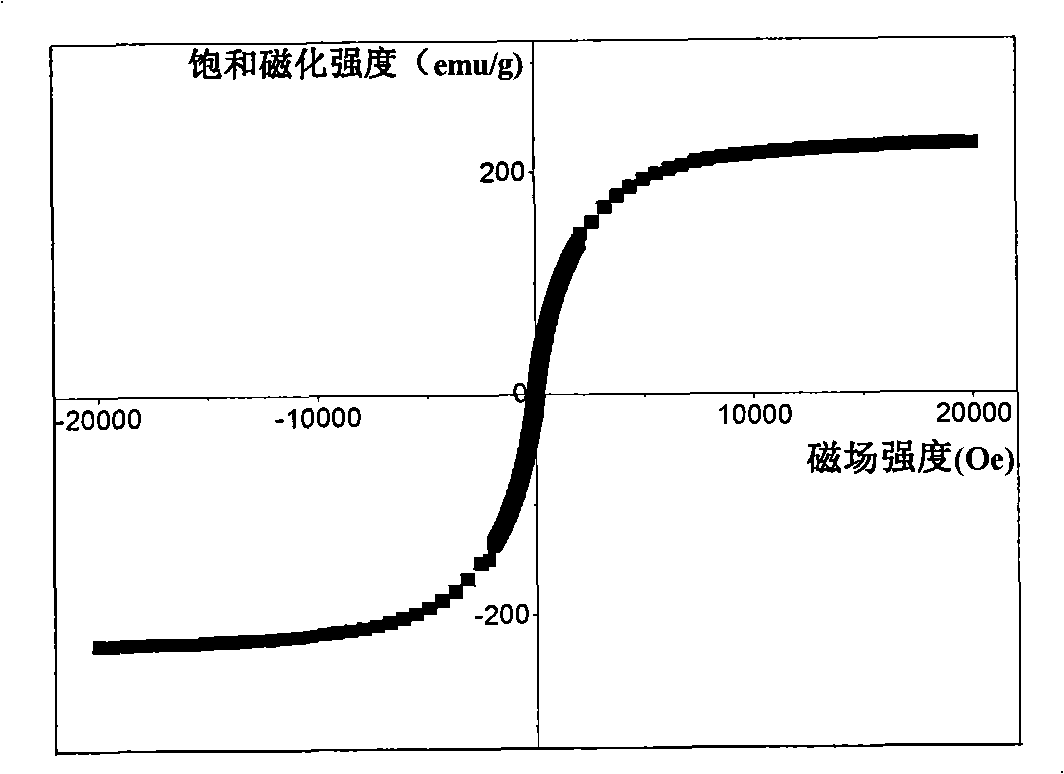

[0020] Weigh 43.5g of Co(NO 3 ) 2 ·6H 2 O and 30.3g of Fe(NO 3 ) 3 9H 2 O to join to CO 2 Water is configured into a 150ml mixed solution, and another 18g of NaOH is weighed and added to remove CO 2 Water is configured into 150ml alkali solution. The two were uniformly mixed under high-speed stirring at 3000 rpm, and the resulting slurry had a pH of 6.8, and was stirred and crystallized at 80°C and 200 rpm for 24 hours. After crystallization, the slurry was cooled and filtered to remove CO 2 Washing with water, centrifugation, and the resulting precipitate were repeated four times, and dried at 60°C for 24 hours to obtain Co 0.63 Fe 0.37 (OH) 2 (NO 3 ) 0.37 2H 2 O. After grinding, weigh 0.15g of hydrotalcite precursor, spread it evenly on a porcelain boat and place it in a tube furnace. 2 / N 2 5% reducing atmosphere, cross-sectional air flow 40ml / cm 2 Under the condition of min, the temperature is programmed to rise at 5°C / min, and the temperature is kept at 6...

Embodiment 2

[0022] Weigh 39.1g of Co(NO 3 ) 2 ·6H 2 O and 36.3g of Fe(NO 3 ) 3 9H 2 O to join to CO 2 Water is configured into a 150ml mixed solution, and another 18g of NaOH is weighed and added to remove CO 2 Water is configured into 150ml alkali solution. The two were uniformly mixed under high-speed stirring at 3000 rpm, and the resulting slurry had a pH of 7.1, and was stirred and crystallized at 40°C and 200 rpm for 24 hours. After crystallization, the slurry was cooled and filtered to remove CO 2 Washing with water, centrifugation, and the resulting precipitate were repeated four times, and dried at 60°C for 24 hours to obtain Co 0.54 Fe 0.46 (OH) 2 (NO 3 ) 0.46 2H 2 O. After grinding, weigh 0.15g of hydrotalcite precursor, spread it evenly in a porcelain boat and place it in a tube furnace. 2 / N 2 5% reducing atmosphere, cross-sectional air flow 40ml / cm 2 Under the condition of min, the temperature is programmed to rise at 5°C / min, and the temperature is kept at 6...

Embodiment 3

[0024] Weigh 58.7g of Co(NO 3 ) 2 ·6H2 O and 27.3g of Fe(NO 3 ) 3 9H 2 O to join to CO 2 Water is configured into a 150ml mixed solution, and another 21.6g of NaOH is weighed and added to remove CO 2 Water is configured into 150ml alkali solution. The two were uniformly mixed under high-speed stirring at 3000 rpm, and the resulting slurry had a pH of 7.0, and was stirred and crystallized at 40°C and 200 rpm for 24 hours. After crystallization, the slurry was cooled and filtered to remove CO 2 Washing with water, centrifugation, and the resulting precipitate were repeated four times, and dried at 60°C for 24 hours to obtain Co 0.54 Fe 0.46 (OH) 2 (NO 3 ) 0.46 2H 2 O. After grinding, weigh 0.15g of hydrotalcite precursor, spread it evenly in a porcelain boat and place it in a tube furnace. 2 / N 2 5% reducing atmosphere, cross-sectional air flow 40ml / cm 2 Under the condition of min, the temperature is programmed to rise at 5°C / min, and the temperature is kept at 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com