Method for pulling silicon core by crystal crushed material and device for applying same

A technology of crystals and scraps, which is applied in the field of polysilicon to draw silicon cores, can solve the problems of increasing the cost of silicon core drawing, cumbersome processing of silicon cores, and prolonged reuse time, so as to achieve low artificial comprehensive cost and omit the reduction process , Heating effect evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention can be explained in more detail with reference to the following examples; however, the present invention is not limited to these examples.

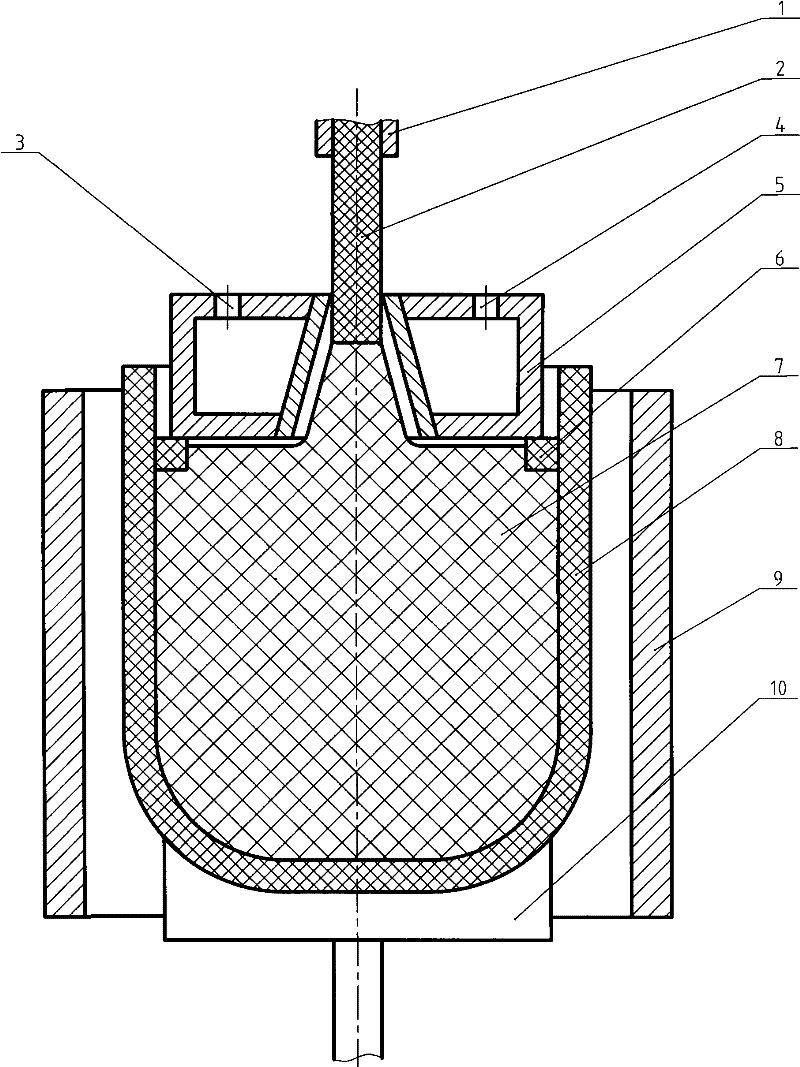

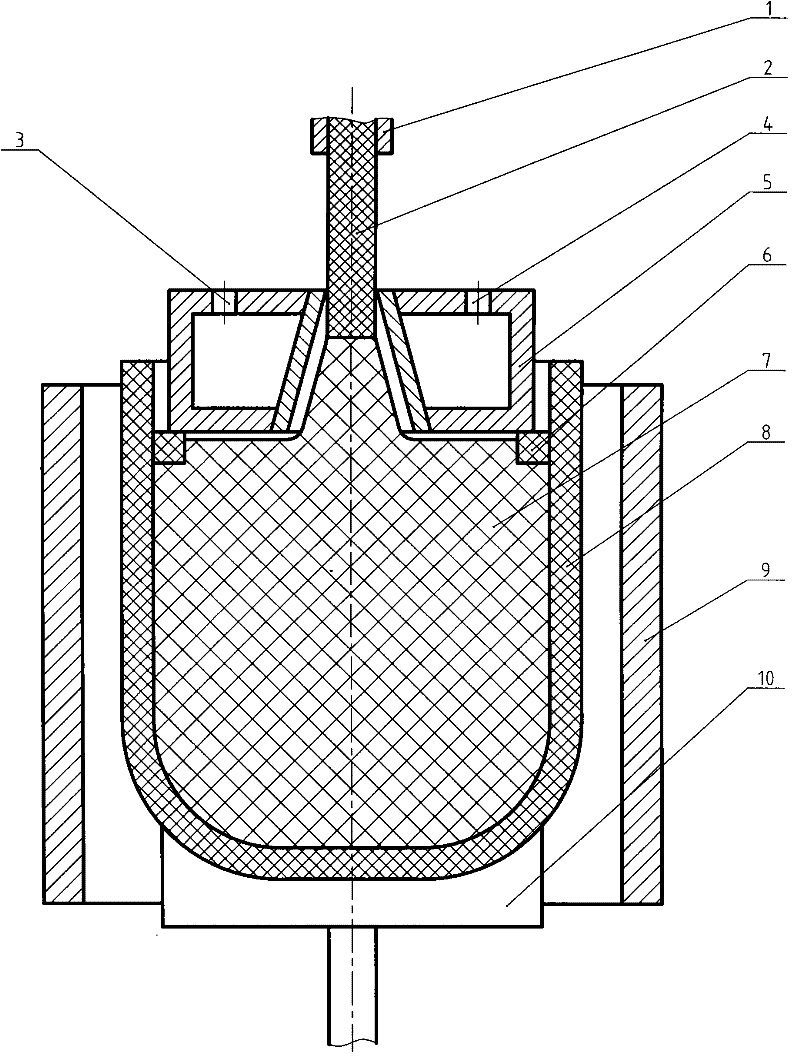

[0022] exist figure 1 Middle; a device for drawing silicon cores from crystal scraps, including a crucible 8 and a heating mantle 9 for melting crystal scraps 7; a guide mold structure for cooling the seed crystal; The crucible 8 and the heating jacket 9 include a crucible 8, a heating jacket 9, and a crucible support body 10. The crucible 8 is provided with a heating jacket 9, and a distance of 3-10 centimeters is left between the crucible 8 and the heating jacket 9. A crucible support 10 is provided at the bottom of the crucible 8, and a guide mold support 6 is provided on the upper inner surface of the crucible 8; the guide mold structure for cooling the seed crystal, the guide mold 5 is placed on the guide mold On the support 6, the guide mold 5 is a cavity structure, and a cooling water port A3 and a coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com