Harmless processing method of raw and fresh food

A technology of harmless treatment and food, applied in the field of harmless treatment of fresh food, can solve the problems of low ozone utilization rate, poor efficiency, and environmental hazards, and achieve the effect of improving the effect and improving the treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

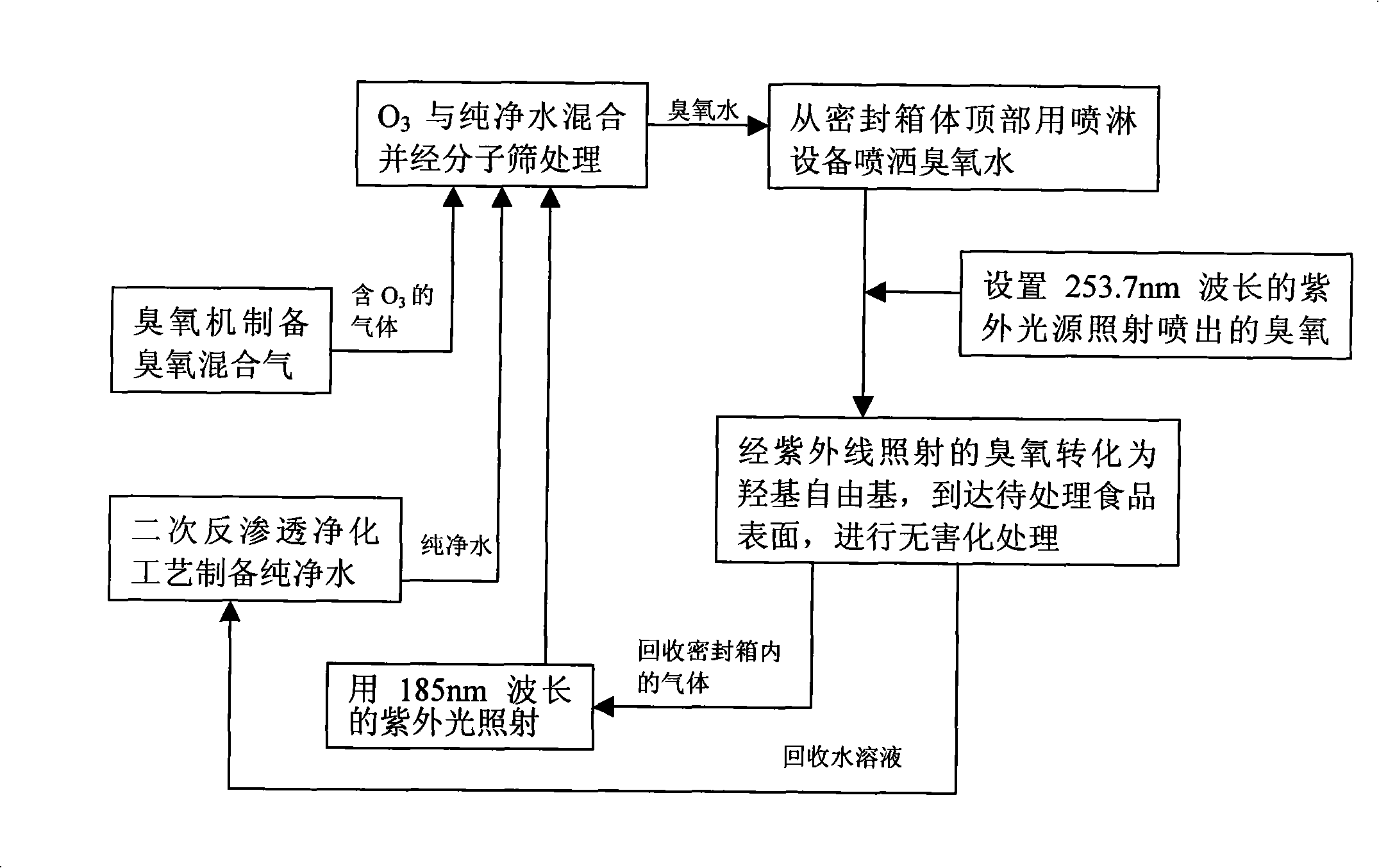

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

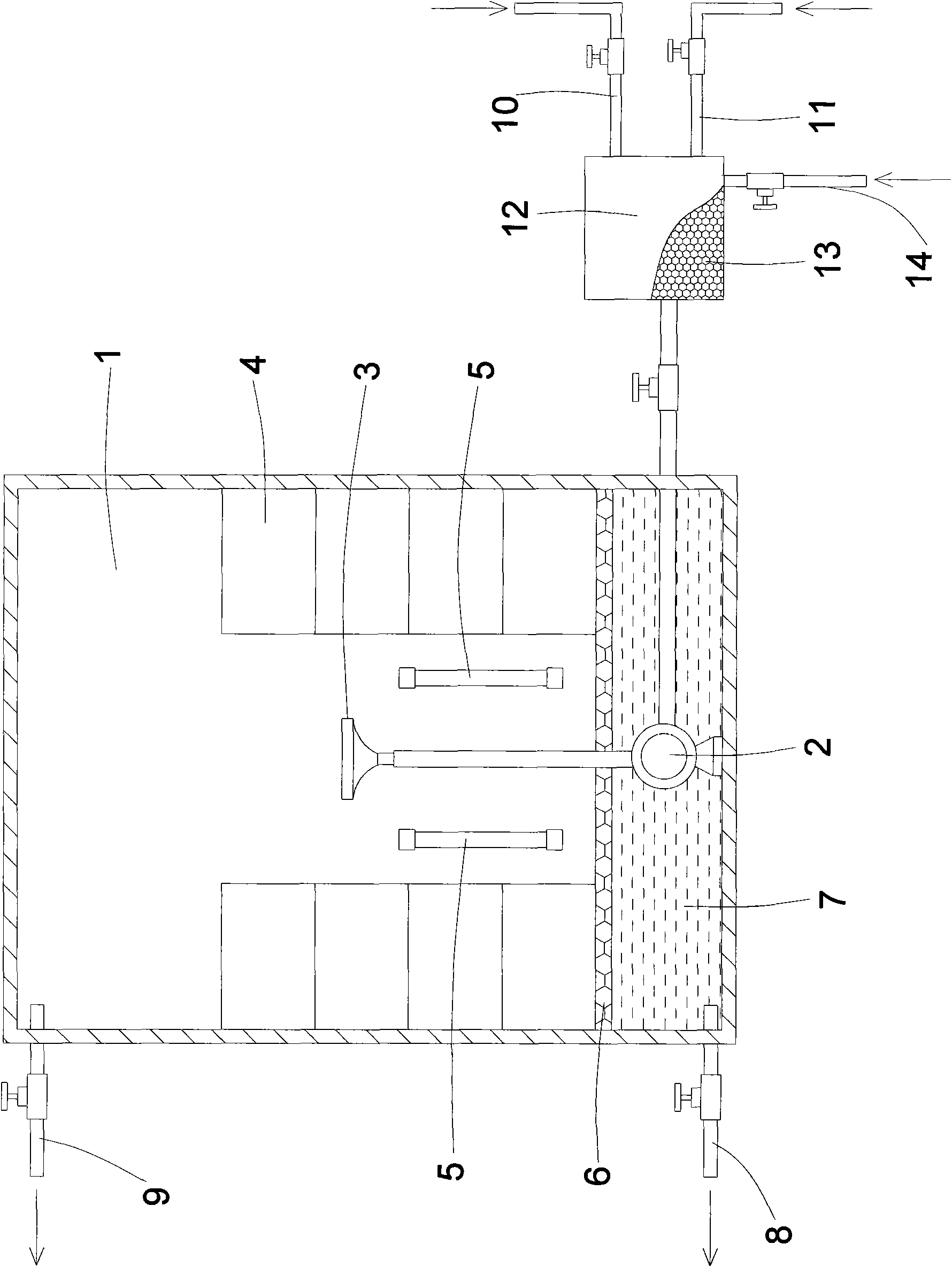

[0047] Embodiment 1 carries out harmless treatment to 50 tons of fresh lychees

[0048] 1) conventional ozone machine (can prepare 1kg O per hour) by gas inlet pipe 11 3 ) prepared containing 10% O 3 and 90% O 2 The mixed gas continues to flow into the mixing tower 12, and at the same time, the purified water treated by secondary reverse osmosis is also continuously introduced into the mixing tower 12 through the pure water inlet pipe 10, and the mixed gas and pure water pass through the built-in molecular sieve in the mixing tower 12 13 processing, generated containing O 3 aqueous solution and containing O 3 , O 2 The mixed gas; among them, containing O 3 O in aqueous solution 3 The concentration is about 20mg / L; the ratio of the mixed gas to pure water is 1L of pure water to 200mg O 3 gas.

[0049] 2) 50 tons of lychees to be processed are stacked near the four walls in the sealed box 1, then the mixed gas and aqueous solution obtained in step 1) are continuously int...

Embodiment 2

[0053] Example 2 Harmless treatment of 50 tons of raw pork

[0054] Process and method are the same as embodiment 1, the difference is:

[0055] The ozone machine used can produce 2kg O per hour 3 ;

[0056] The ratio of mixed gas and pure water prepared by the ozone machine is 1L pure water to 400mg O 3 gas;

[0057] The number of ultraviolet lamps 5 arranged in the sealed box is between 60 and 80;

[0058] Step 3) The number of ultraviolet light lamps used to process the recovered gas is also between 60 and 80.

[0059] During the above-mentioned treatment process, about 2kg O was prepared in total by the conventional ozone machine. 3 ; After gas recovery in the treatment process, through 185nm ultraviolet treatment to obtain about 2kgO 3 ; Recycle about 20 tons of pure water; calculated based on this, to process 50 tons of raw pork, only 80mg O per kilogram is used 3 Harmless treatment has been realized.

Embodiment 3

[0060] Example 3 Harmless treatment of 50 tons of fresh shrimp

[0061] Process and method are the same as embodiment 1, the difference is:

[0062] The ozone machine used can produce 2.5kg O per hour 3 ;

[0063] The ratio of mixed gas and pure water prepared by the ozone machine is 1L of pure water to 500mg O 3 gas;

[0064] The number of ultraviolet lamps 5 arranged in the sealed box is between 80 and 100;

[0065] Step 3) The number of ultraviolet light lamps used to process the recovered gas is also between 80 and 100.

[0066] During the above-mentioned treatment process, about 2.5kg O was prepared in total by the conventional ozone machine 3 ; After gas recovery in the treatment process, about 2.5kg O was obtained after 185nm ultraviolet treatment 3 ; Recycle about 25 tons of pure water; calculated based on this, to process 50 tons of fresh shrimp, only 100mg O is used per kilogram 3 Harmless treatment has been realized.

[0067] The various foods processed by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com