Ultra-large type head plate integral pressing and molding technology and safe shell sealing head

A technology of overall pressing and forming process, applied in manufacturing tools, sealing, nuclear engineering, etc., can solve the problems of affecting the service life of workpieces, low production efficiency, easy to produce sharp points, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

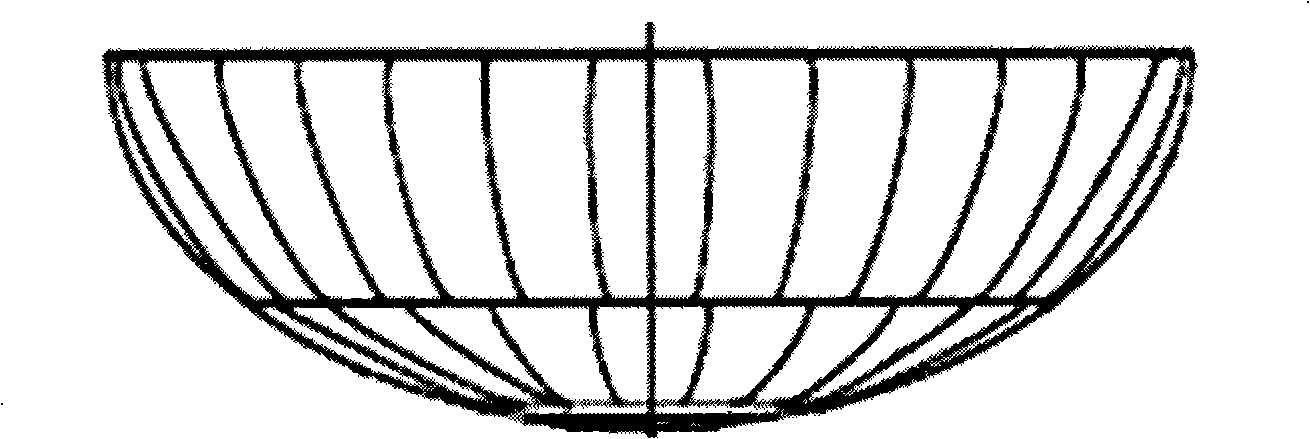

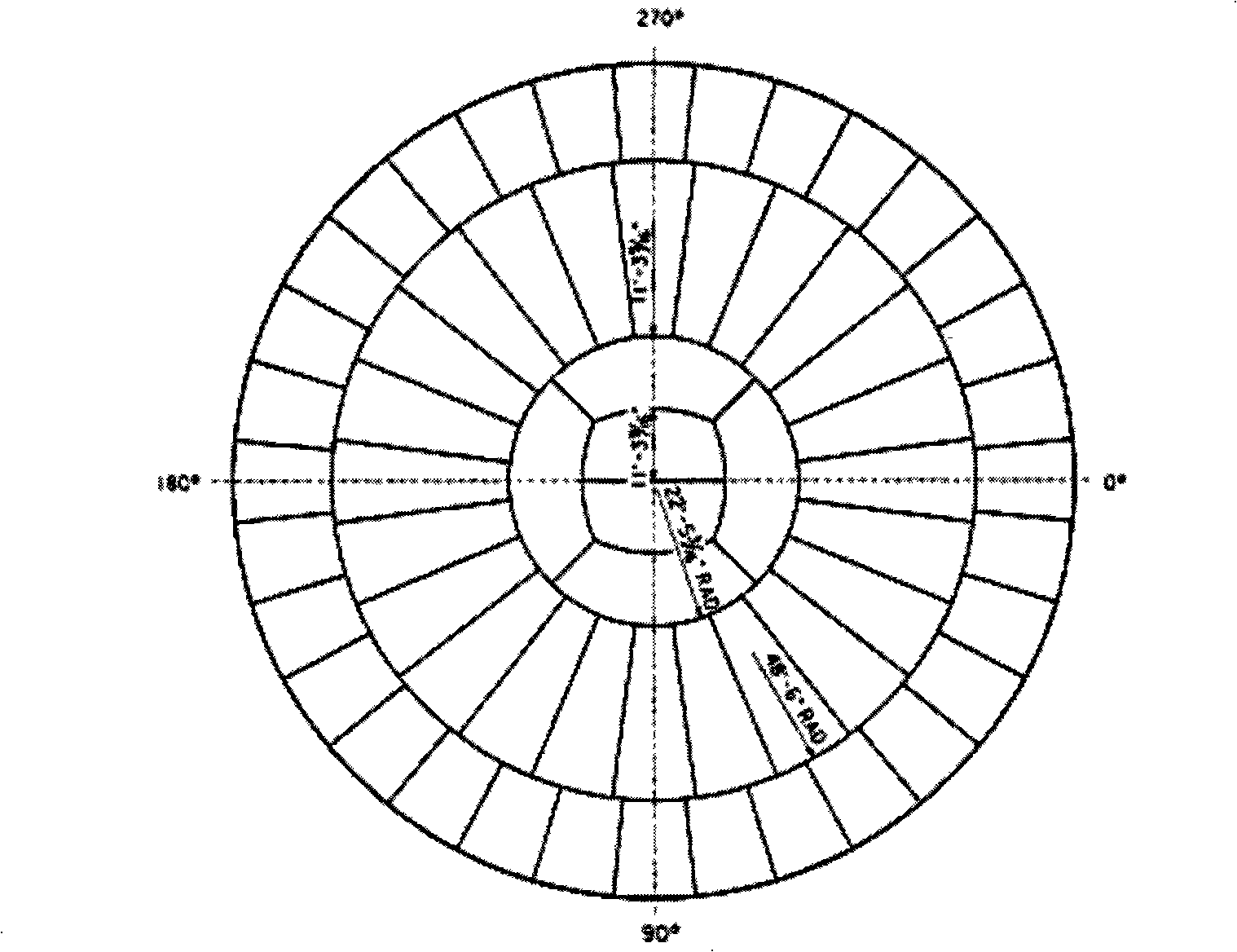

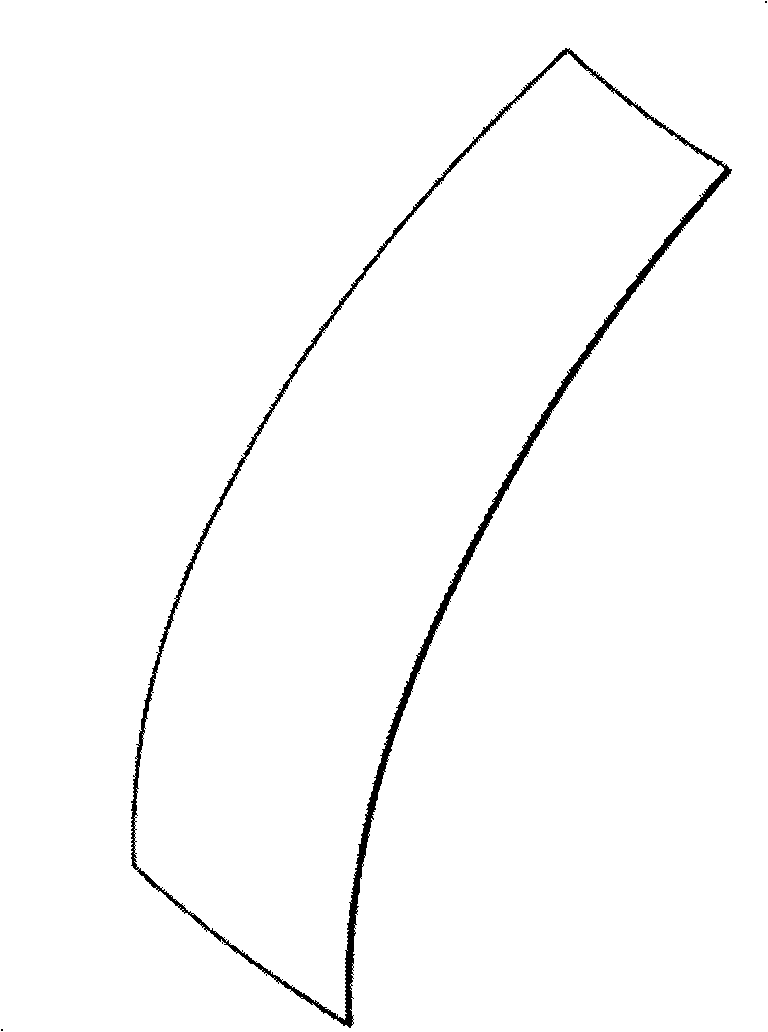

[0039] The overall pressing and forming process of super-large head plate includes the following steps: (see Figure 1-4 , figure 1 The elliptical head with a ratio of 1:1.728 is simplified to 5 curvatures, one of which has two curvatures. )

[0040] 1. Flame cutting of steel plate:

[0041] The flame cutting machine is used to cut the steel plate according to the shape and size requirements of the flaps of different layers of the head, and reserve the heat-affected zone caused by flame cutting and the cutting size of the corner after pressing, and check the size of the blank after cutting.

[0042] 2. Heating and heat preservation of steel plate:

[0043]Before the steel plate is pressed, it needs to be heat treated in a custom-made heating furnace. The heating temperature is 550-600 ° C and the heat preservation is at least 90 minutes. The steel plate is heated by the flame heating method, and the heating furnace includes 6 nozzles in total, and the speed of each flame n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com