Oxygenation and dimethyl diallyl ammonium chloride composite modification silicoferrite coagulating agent and preparation method thereof

A dimethyl diallyl ammonium chloride, compound modification technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., to achieve the effect of high efficiency, low price, high positive charge density and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

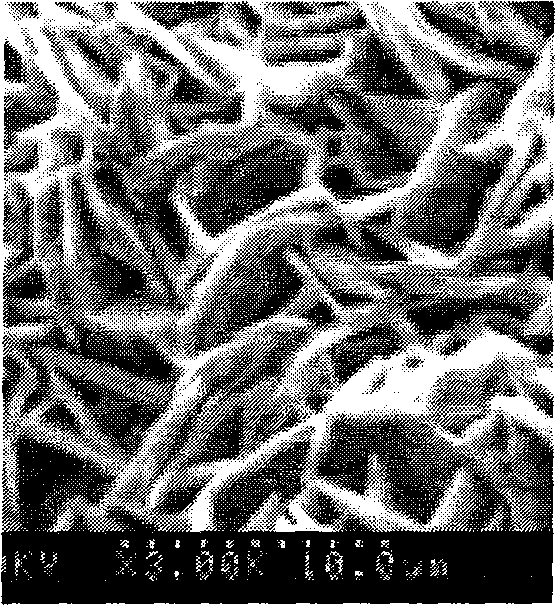

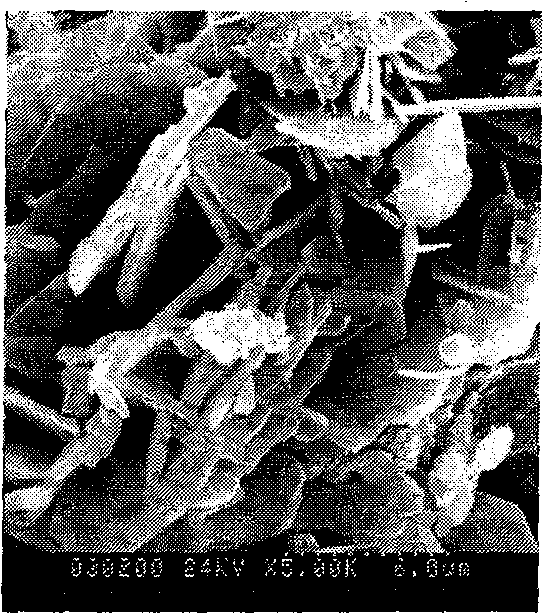

Image

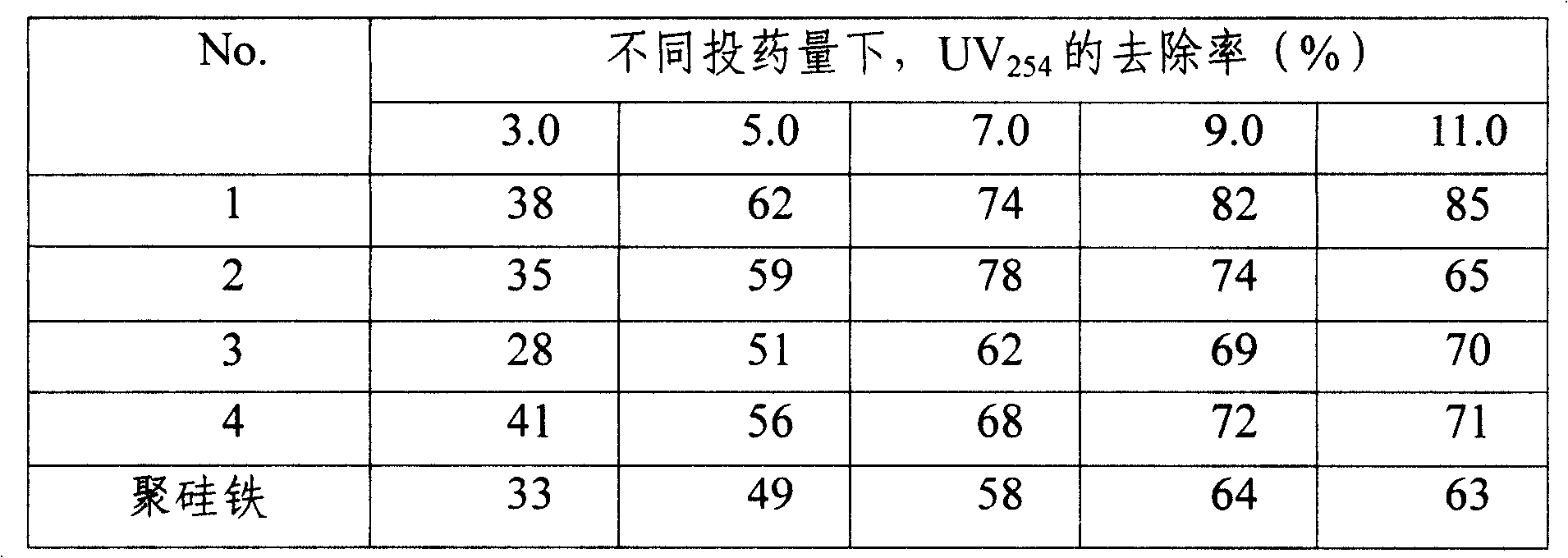

Examples

Embodiment 1

[0038]Dilute 20L of water glass with 65L of water to the desired concentration. Under the condition of stirring at a temperature of 20°C to 50°C and 300 rpm to 500 rpm, add the above-mentioned diluted water glass to 5L of dilute sulfuric acid (40%) solution, and control the pH value to 4, 6 minutes Then stop stirring and polymerize for 1 hour to obtain activated silicic acid, which is ready for use. At a temperature of 35°C to 60°C, add 57kg of ferrous sulfate heptahydrate to 31L of dilute sulfuric acid (40%) solution, and stir for 10 minutes at a speed of 200 to 500 rpm to obtain sulfuric acid ferrous solution. At a temperature of 35°C to 60°C and a stirring speed of 200 rpm to 500 rpm, the activated silicic acid to be used, 4.2L of dimethyl diallyl ammonium chloride and 3.5kg of oxidant were simultaneously Add it into the above-mentioned ferrous sulfate solution, stop stirring after 15 minutes, and make a composite modified ferrosilicon coagulant semi-finished product. Pu...

Embodiment 2

[0040] Dilute 20L of water glass with 80L of water to the desired concentration. Under the condition of stirring at a temperature of 20°C to 50°C and 300 rpm to 500 rpm, add the above-mentioned diluted water glass to 5L of dilute sulfuric acid (40%) solution, and control the pH value to 3 for 6 minutes Then stop stirring and polymerize for 2 hours to obtain activated silicic acid for use. At a temperature of 35°C to 60°C, add 30kg of ferrous sulfate heptahydrate to 18L of dilute sulfuric acid (40%) solution, and stir for 10 minutes at a speed of 200 to 500 rpm to obtain sulfuric acid ferrous solution. At a temperature of 35°C to 60°C and a stirring speed of 200 rpm to 500 rpm, the activated silicic acid to be used, 3.8L of dimethyl diallyl ammonium chloride and 2.5kg of oxidant were simultaneously Add it into the above-mentioned ferrous sulfate solution, stop stirring after 15 minutes, and make a composite modified ferrosilicon coagulant semi-finished product. Put the semi-...

Embodiment 3

[0042] Dilute 20L of water glass with 90L of water to the desired concentration. Under the condition of stirring at a temperature of 20°C to 50°C and 300 rpm to 500 rpm, add the above-mentioned diluted water glass to 5L of dilute sulfuric acid (40%) solution, control the pH value to 2.5, and wait for 6 minutes Then stop stirring and polymerize for 3 hours to obtain activated silicic acid for use. At a temperature of 35°C to 60°C, 16kg of ferrous sulfate heptahydrate was added to 13.3L of dilute sulfuric acid (40%) solution, and stirred at a speed of 200 to 500 rpm for 10 minutes to obtain ferrous sulfate solution. At a temperature of 35°C to 60°C and a stirring speed of 200 rpm to 500 rpm, the activated silicic acid to be used, 2.8L of dimethyl diallyl ammonium chloride and 1.4kg of oxidant were simultaneously Add it into the above-mentioned ferrous sulfate solution, stop stirring after 15 minutes, and make a composite modified ferrosilicon coagulant semi-finished product. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com