Separation process for material containing lead, antimony, copper, bismuth and silver

A technology of bismuth, silver and materials, applied in the field of separation and enrichment of non-ferrous metals, can solve the problem of no comprehensive recovery of metals, and achieve the effect of relieving the pressure of outsourcing and high direct yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

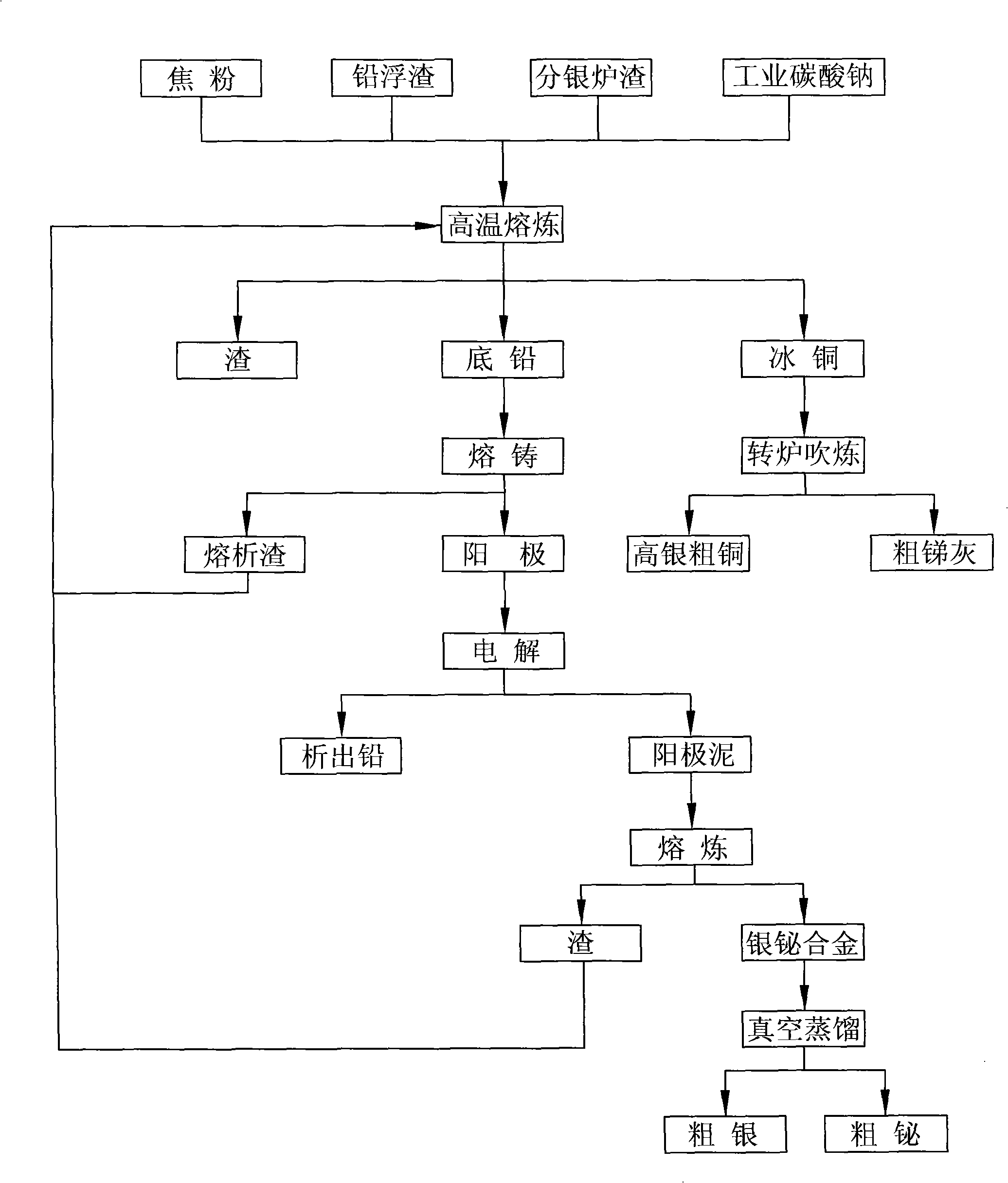

[0010] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0011] see figure 1 , a separation process of lead-containing antimony-copper-bismuth-silver material, using lead-containing antimony-copper-bismuth-silver material as raw material for processing, the chemical composition and content of the lead-containing antimony-copper-bismuth-silver material are: Pb5~20%, Ag2~ 10%, Cu15-30%, Bi10-25% and Sb3-10%.

[0012] When the above raw materials are at a temperature of 1200°C, the weight of sodium carbonate added is 7% of the weight of the raw materials, the weight of coke powder is 7% of the weight of the raw materials, and the weight of lead oxide slag added is twice the weight of the raw materials, and the layers are separated during smelting After 2 hours, 98% of Bi, 80% of Ag and 95% of Pb in the raw material entered into the bottom lead, and 95% of Cu, 20% of Ag and 95% of Sb in the raw material entered into matte;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com