Method for preparing high-purity nickel ingot

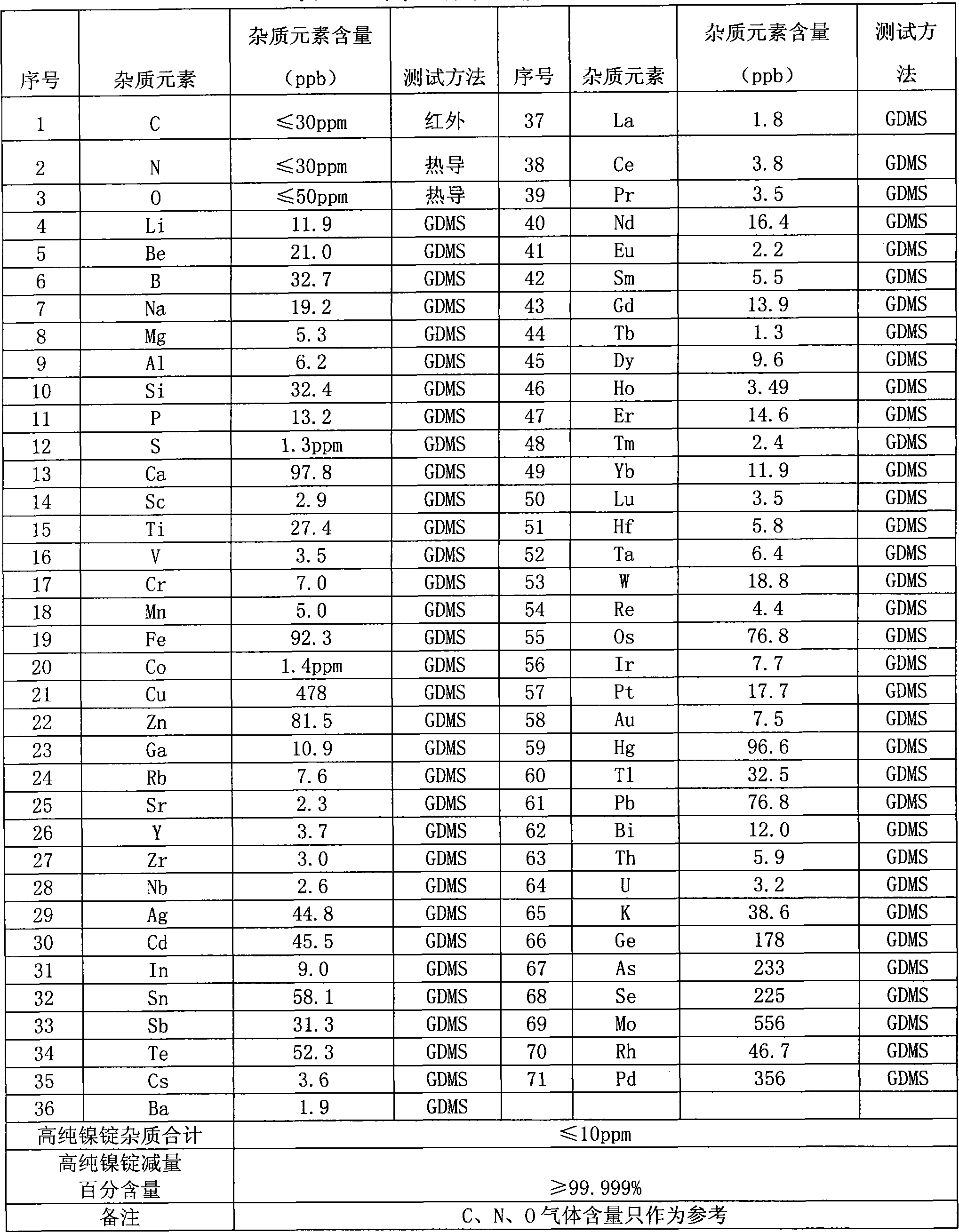

A nickel ingot and high-purity technology, applied in the field of preparing high-purity nickel ingots, can solve the problems of difficult removal of individual impurity elements, single product specifications and high production costs, and achieve the effects of diversification, product quality improvement, and fast melting speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] A method for preparing high-purity nickel ingots, the specific operations of the preparation process are as follows:

[0012] a. Using 5N (purity greater than 99.999%) electrolytic nickel as raw material, cut the electrolytic nickel plate according to the charging requirements, and after successively pickling, ultrasonic cleaning, vacuum drying, and binding, the bound nickel The material is manually placed on the conveying roller table in the electron beam furnace, and the furnace door is closed;

[0013] b. Supply water, electricity and gas to the equipment to ensure that the cooling water circulation of each part is smooth, the power supply is in place, and the compressed air supply is normal;

[0014] c. Turn on the diffusion pump for preheating. After 2 hours, turn on each vacuum pump and corresponding valves in order to vacuumize the furnace body and gun chamber. The final vacuum of the gun chamber is 6.3×10 -4 Pa, focus vacuum is 5.3×10 -4 Pa, the vacuum in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com