Leaching rate prediction and optimization operation method in wet metallurgical leaching process

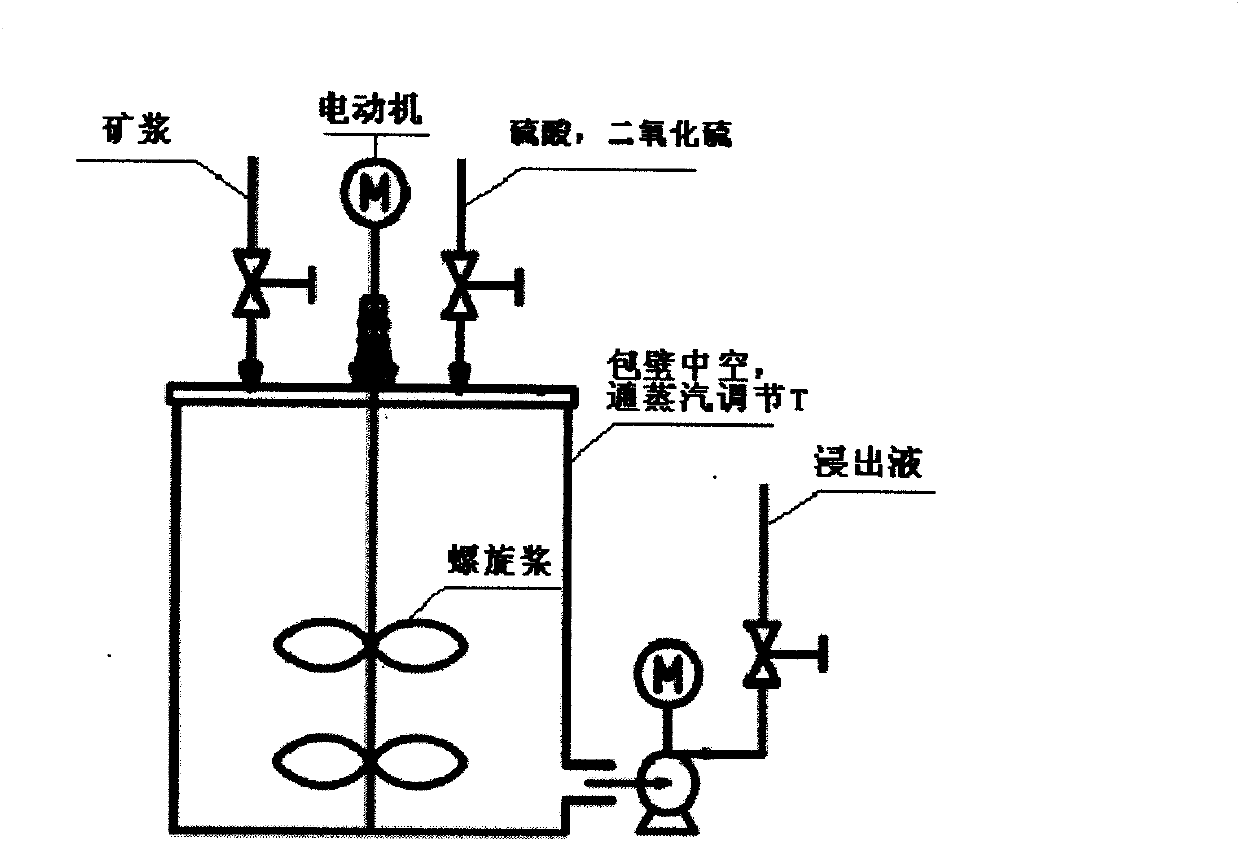

A technology for hydrometallurgy and operation optimization, applied in the direction of electrical program control, process efficiency improvement, comprehensive factory control, etc., can solve the problems of high energy consumption, rough production operation, long leaching time, etc., and achieve the effect of uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

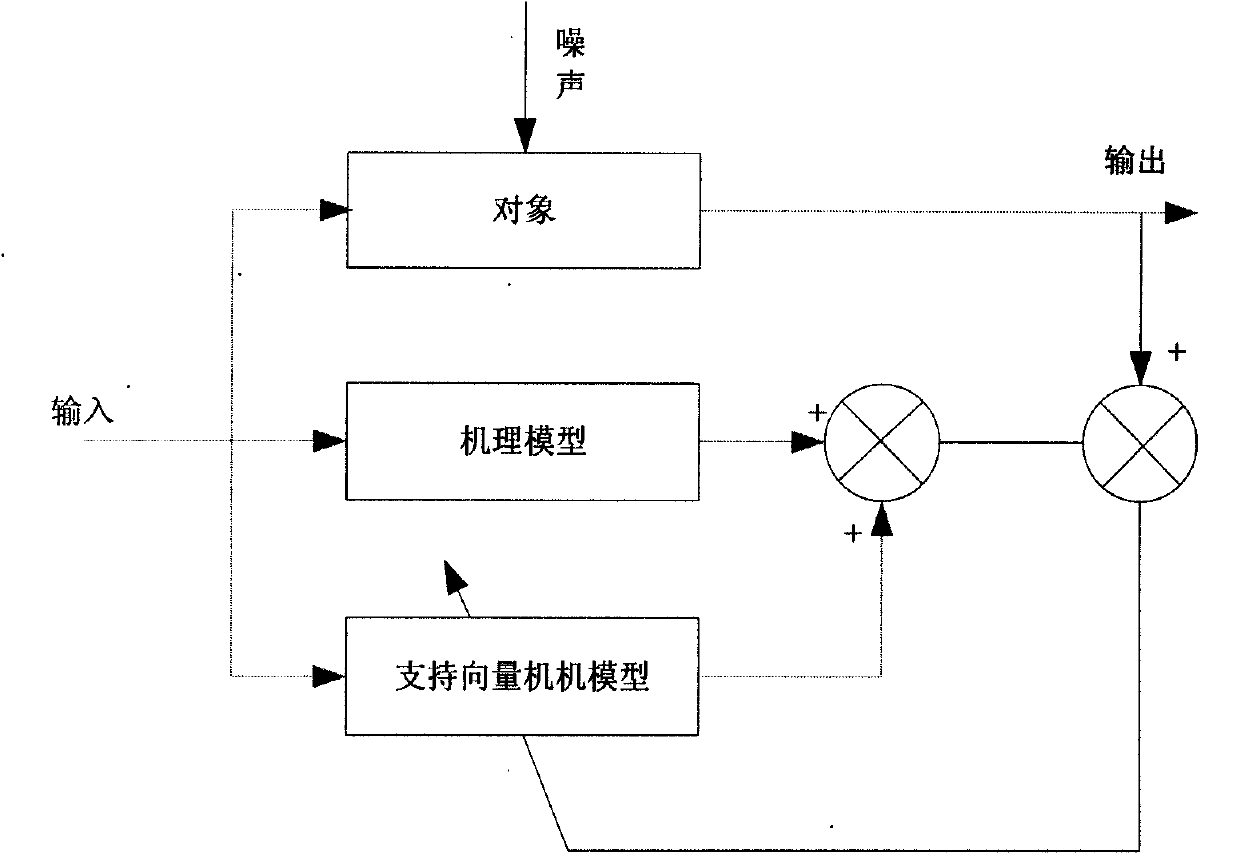

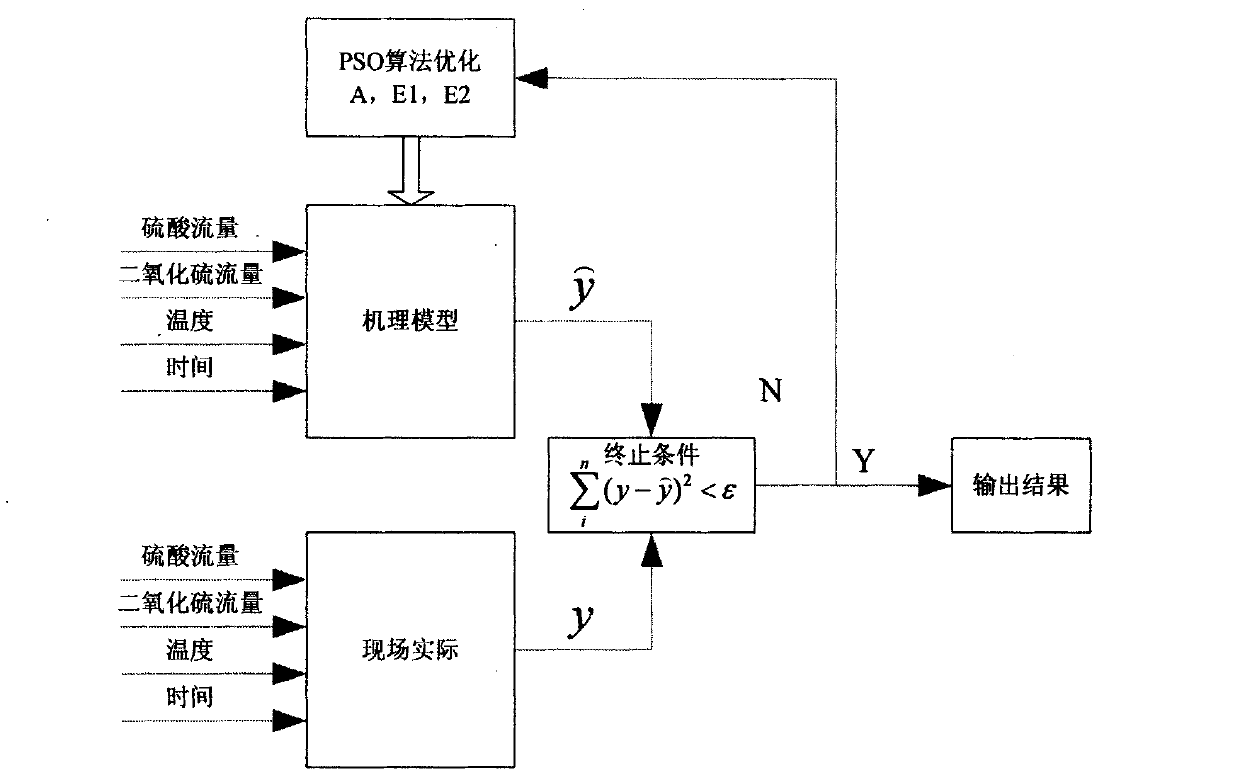

Method used

Image

Examples

Embodiment 1

[0154] Example 1: Prediction model of leaching rate of leaching tank 1#

[0155] 1. Independent variables and dependent variables of the prediction model: temperature of the leaching solution in the leaching tank (CAO_TEM, K), PH value of the leaching solution in the leaching tank (CAO_PH), SO 2 Traffic (CAO_SO 2 , ml / s), the incoming sulfuric acid flow (CAO_H 2 SO 4 , L / s), leaching time (TIME, s), leaching rate (JINCHULV, %).

[0156] 2. Data set: Two-month production data (independent variable and dependent variable) of the leaching tank of the leaching production line are collected. The online data is collected every 30 seconds, and there are 65 valid samples in the training set.

[0157] In practical applications, the process data comes from the field, and are inevitably affected by factors such as the accuracy, reliability of the measuring instrument and the on-site measurement environment, and inevitably have various measurement errors. The use of low-precision or i...

Embodiment 2

[0174] Example 2: On-line optimization of leaching tank 1#:

[0175] 1. Optimization objective variables and optimization independent variables: take the economic benefits of the leaching tank as the optimization objective, the leaching liquid temperature (CAO_TEM, K) and its loss (QT) in the leaching tank, the SO 2 Traffic (CAO_SO 2 , ml / s) and its loss (Qs), the incoming sulfuric acid flow (CAO_H 2 SO 4 , L / s) and its loss (Q1), stirring motor loss (Qd), leaching time (TIME, s), and leaching rate (y, %).

[0176] 2. Establish a production optimization model: collect the production data of the leaching tank of the leaching production line for two months, the online data is collected every 30 seconds, and the training set has 65 valid samples. The difference between the collected sensor measurement data and the above prediction results and the actual value is composed of input and output data pairs, and the data modeling method is called for training to obtain the parameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com