Waste gas purification method and equipment

A technology for purifying equipment and waste gas, which is applied in the fields of desulfurization, industrial waste gas dedusting and dehydration. It can solve the problems of low purification efficiency, complex process and structure, and large investment, and achieve high purification efficiency, simple structure, and investment savings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, further illustrate the present invention through embodiment.

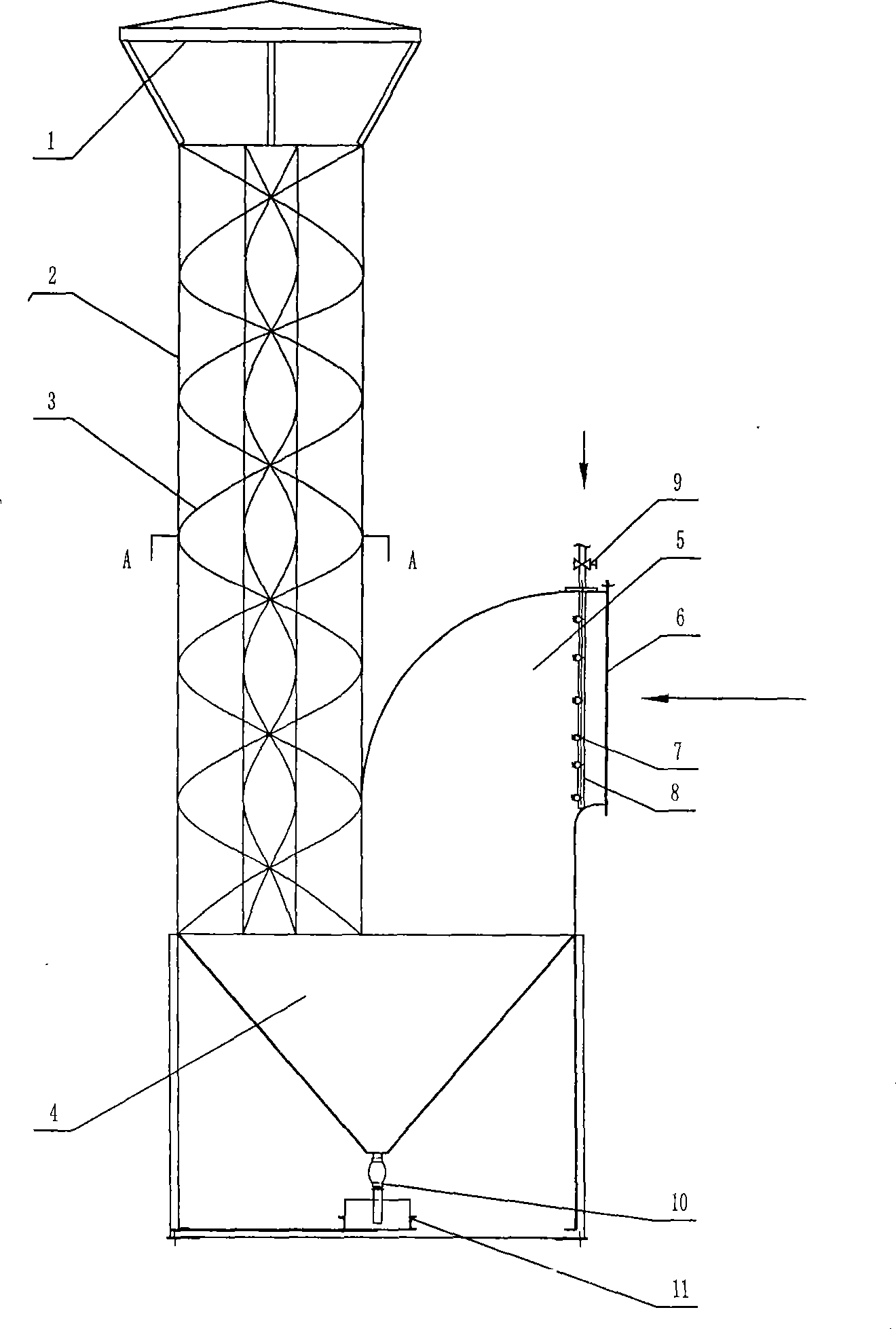

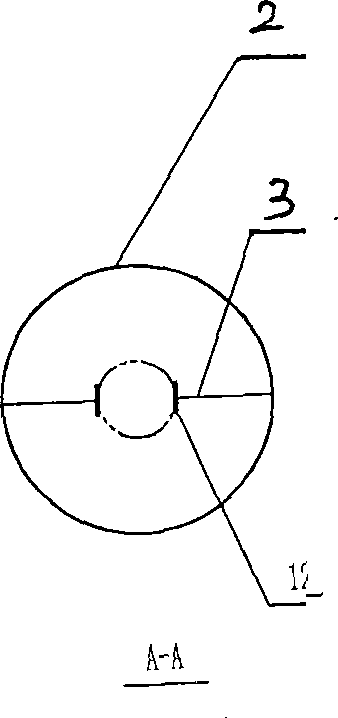

[0021] In the embodiment, the exhaust gas purification equipment includes an exhaust gas inlet 5, a spray device, a sewage tank 4, a spiral channel, and a flue gas outlet. A spiral channel is provided above the sewage tank 4, and a flue gas Export. In this embodiment, there are two helical passages arranged with a difference of 180° on the plane. The center of the helical passage is hollow, and when the smoke passes through, an air column is formed. The helical channel is composed of helical blades 3, and a water baffle 12 is also arranged on the helical blade. The water baffle is close to the said hollow air column, so that the collected sewage droplets will never be blown up again by the air flow. And take away. The exhaust gas inlet 5 is a downward elbow, so that the direction of the exhaust gas flow is downward first. The spray device includes a spray noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com