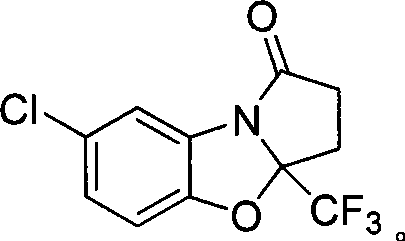

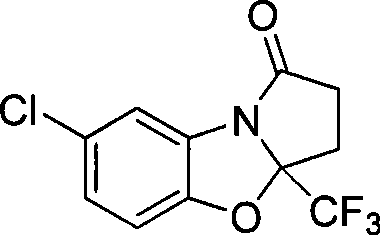

7-chlorine-3a-(trifluoromethyl)-3, 3a-dihydrobenzo (d) pyrrole (2, 1-b)-oxazole-1(2H)-ketone and synthetic method thereof

A technology of trifluoromethyl and dihydrobenzene, applied in 7-chloro-3a-(trifluoromethyl)-3

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

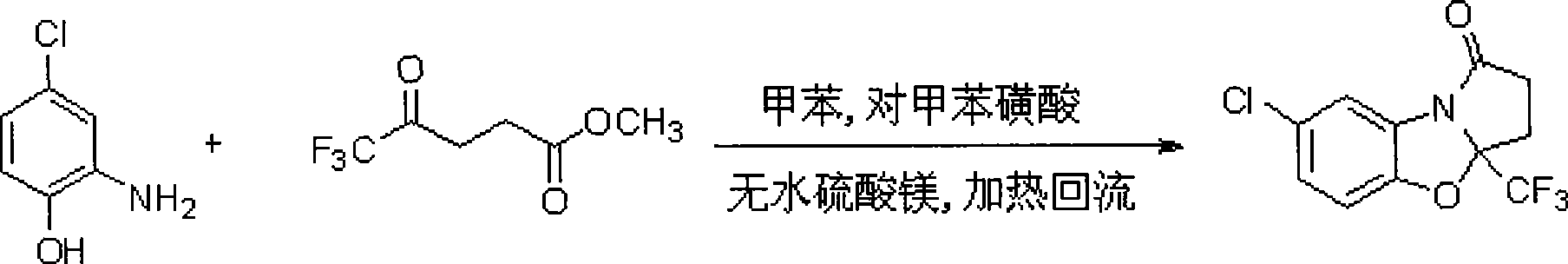

Method used

Image

Examples

Embodiment 1

[0029] Example 1: ①In a 50 ml round-bottomed flask equipped with a reflux condenser, add 0.44 g of methyl trifluoroγ-ketoate, 0.019 g of p-toluenesulfonic acid, 25 ml of toluene, and 0.2 g of anhydrous magnesium sulfate . The above mixture was stirred and refluxed in an oil bath for half an hour, and then 0.287 g of 2-amino-4-chlorophenol was added; ② the reaction solution gradually turned red under reflux. After 12 hours of reaction, 0.019 g of p-toluenesulfonic acid was added. The reaction was continued for 12 hours and then stopped. After the reaction was completed, the anhydrous magnesium sulfate was removed by suction filtration, and the filtrate was concentrated. ③ The obtained concentrated solution was separated by silica gel chromatography, and the developing solvent was a mixed solvent of petroleum ether and ethyl acetate with a volume ratio of 6:1 to obtain 0.38 g of an off-white solid with a yield of 68%.

Embodiment 2

[0030] Example 2: ① In a 250 ml round-bottomed flask equipped with a reflux condenser, add 11 g of methyl trifluoroγ-ketoate, 0.475 g of p-toluenesulfonic acid, 150 ml of toluene, and 5 g of anhydrous magnesium sulfate . The above mixture was stirred and refluxed in an oil bath for half an hour, and then 7.25 g of 2-amino-4-chlorophenol was added; ② the reaction solution gradually turned red under reflux. After 12 hours of reaction, 0.475 g of p-toluenesulfonic acid was added. The reaction was continued for 24 hours and then stopped. After the reaction was completed, the anhydrous magnesium sulfate was removed by suction filtration, and the filtrate was concentrated. ③ The obtained concentrated solution was separated by silica gel chromatography, and the developing solvent was a mixed solvent of petroleum ether and ethyl acetate with a volume ratio of 6:1 to obtain 9.14 g of an off-white solid with a yield of 66%.

Embodiment 3

[0031] Example 3: ① In a 2-liter round-bottomed flask equipped with a reflux condenser, add 110 grams of methyl trifluoroγ-ketoate, 4.75 grams of p-toluenesulfonic acid, 1000 milliliters of toluene, and 20 grams of anhydrous magnesium sulfate. . The above mixture was stirred and refluxed in an oil bath for half an hour, and then 72.5 g of 2-amino-4-chlorophenol was added. ② The reactant gradually turned red under reflux. After 12 hours of reaction, 4.75 g of p-toluenesulfonic acid was added. The reaction was continued for 32 hours and then stopped. After the reaction was completed, the anhydrous magnesium sulfate was removed by suction filtration, and the filtrate was concentrated. 3. The obtained concentrated solution was separated by silica gel chromatography, and the developing solvent was a mixed solvent of petroleum ether and ethyl acetate with a volume ratio of 6:1 to obtain 87.3 g of an off-white solid with a yield of 63%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com