Device for hot-dip coating Al-Zn (aluminum-zincic) on super high-strength band steel and processing technology

A technology of hot-dip aluminum and strip steel, applied in hot-dip plating process, metal material coating process, coating and other directions, can solve problems such as reducing product strength, and achieve the effect of improving product quality, ensuring strength, and increasing profits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

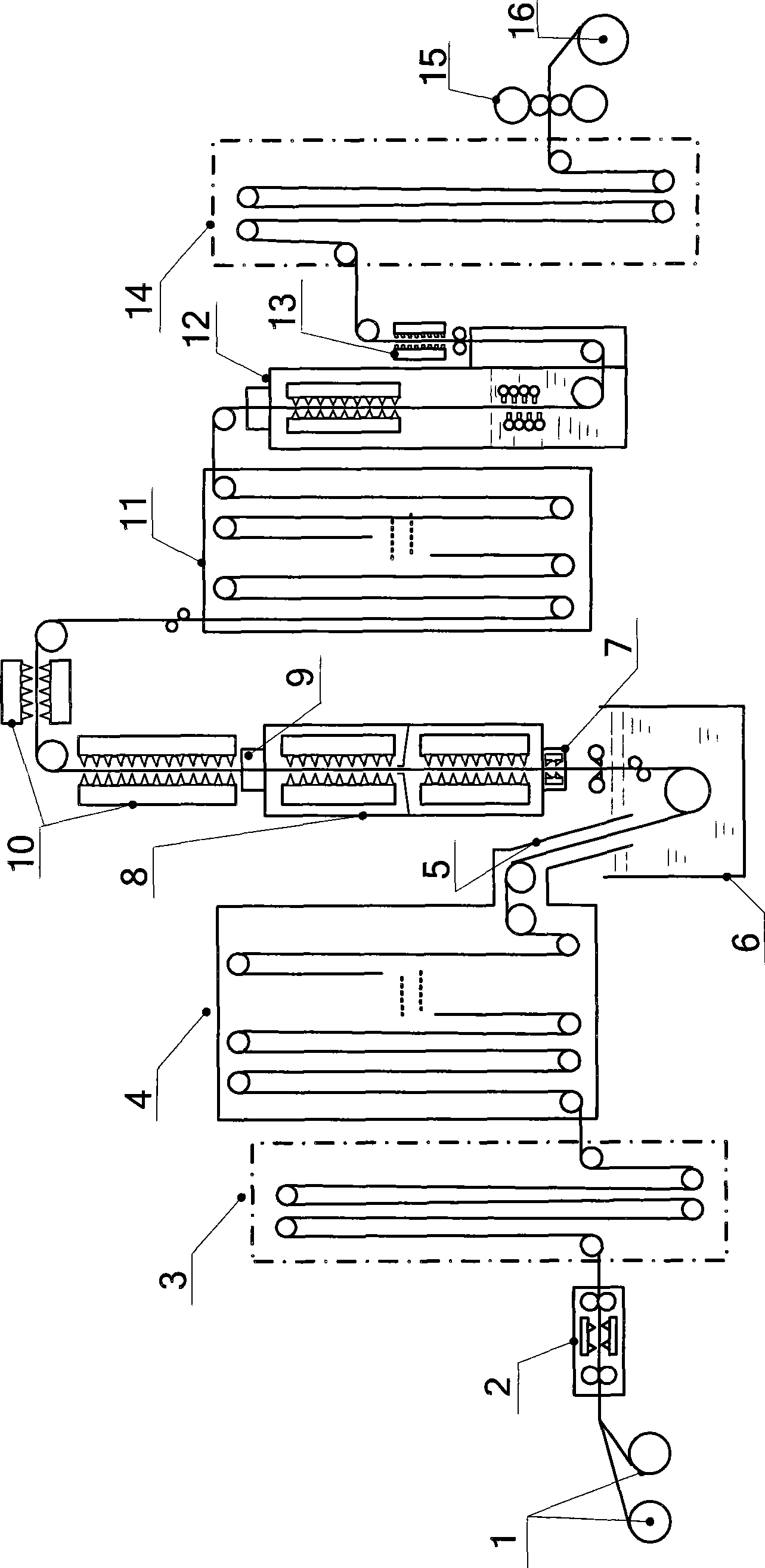

[0018] Such as figure 2 As shown, it includes uncoiler 1, pickling equipment 2, front looper 3, annealing furnace 4, furnace nose 5, aluminum zinc pot 6, lower sealing device 7, rapid cooling device 8, discharge device 9, cooling bellows 10, over Aging furnace 11, water quenching device 12, drying device 13, back looper 14, tempering machine 15, coiler 16.

[0019] Firstly, the steel coil produced in the previous process is uncoiled by the uncoiler 1 and enters the pickling equipment 2 to clean the surface of the steel plate, and then enters the front looper 3 and the continuous annealing furnace 4 . According to the different specifications of the actual strip steel products, the strip steel is heated to 850°C in the continuous annealing furnace 4 for a period of time, then slowly cooled to 600°C and then enters the aluminum-zinc pot 6 filled with aluminum-zinc liquid through the furnace nose 5 for further processing. Hot-dip aluminum-zinc operation, the aluminum-zinc pot 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com