Effective radiator structure of millimeter wave traveling wave tube slow-wave system with wide frequency band and realizing method thereof

A technology of slow wave system and heat dissipation structure, which is applied in the manufacture of electrode systems, manufacture of discharge tubes/lamps, circuit components of time-of-flight electron tubes, etc. It can solve problems such as dielectric clamping rod damage and reduce high-frequency loss , improve heat dissipation capacity, and avoid the effect of process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

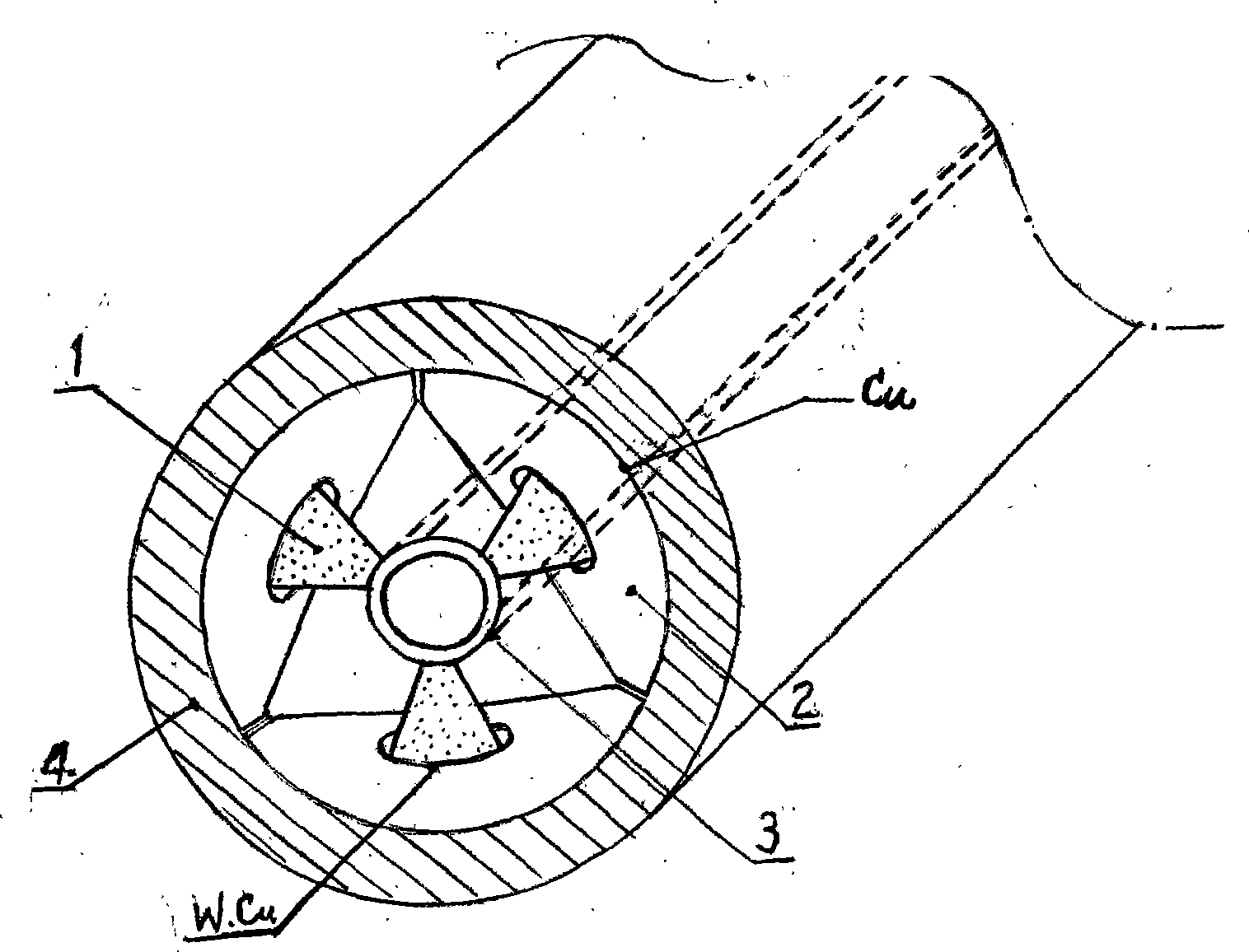

[0017] refer to figure 1 , showing a schematic diagram of loading the loading piece 2 and the helix 3 with the medium clamping rod 1 into the shell 4 . In the figure, the scheme of the traditional cylindrical medium clamping rod is changed to a fan-shaped medium clamping rod, that is, the sawtooth with a fan-shaped surface is arranged longitudinally, and a layer of loading sheet in contact with it is added to the periphery of each sawtooth. The loading sheet A heat-conducting composite metal film is plated on the surface in contact with the medium holding rod; a heat-conducting copper film is plated on the contact surface of the loading piece and the tube shell.

[0018] Adjust the structure of the loading piece so that the loading piece not only contacts the back of the clamping rod, but also contacts the two sides of the clamping rod.

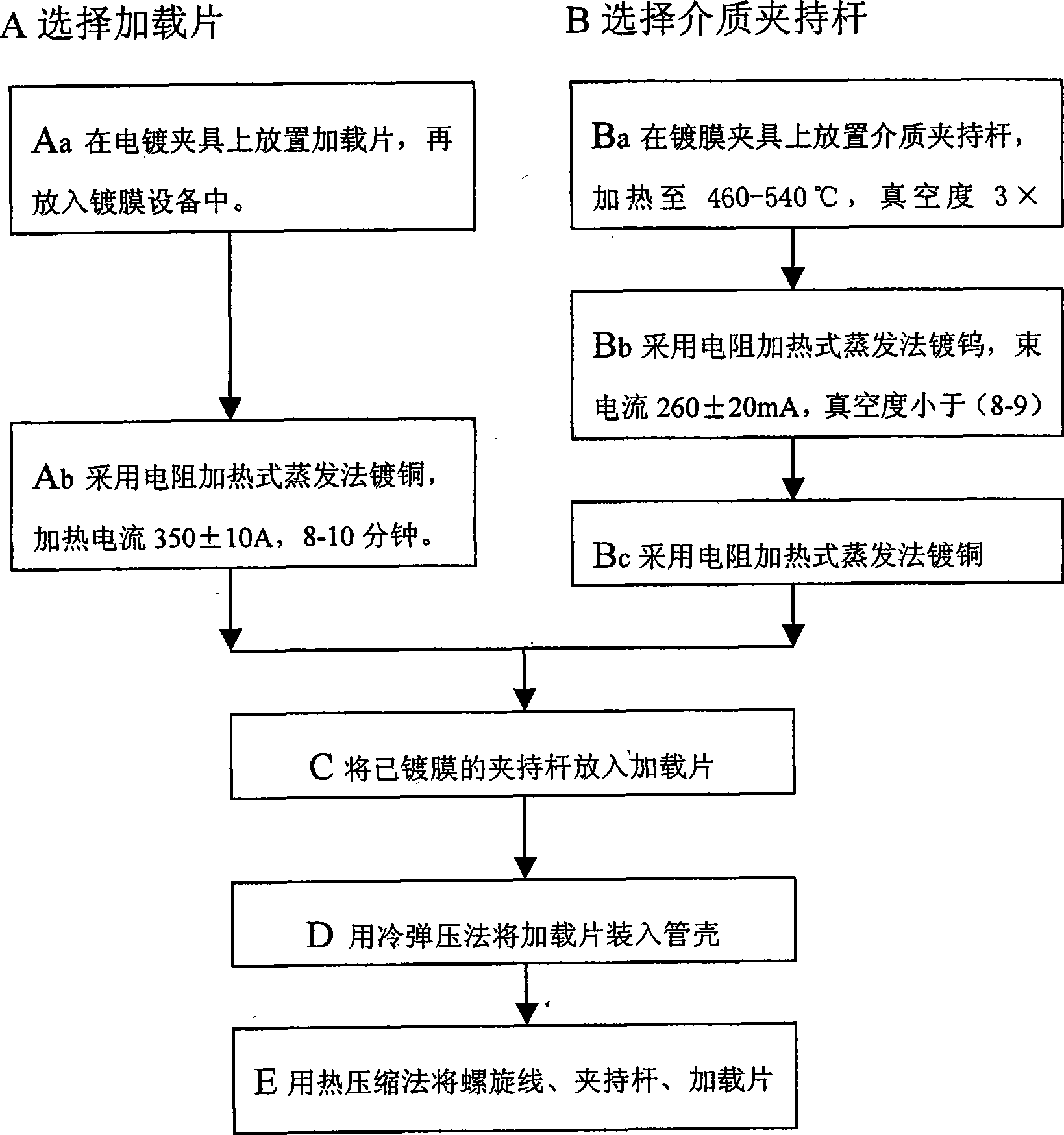

[0019] refer to figure 2 , represents the implementation flow chart of the implementation method of the present invention, and the implem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com