Method for preparing flame-retarding PTT polyester

A polyester and copolymer flame retardant technology, applied in the field of the preparation of flame retardant PTT polyester, can solve the problems of decreased breaking strength of polyester fibers, no elimination of polyester fibers, poor effect, etc. Good effect of delaying combustion and anti-melting dripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

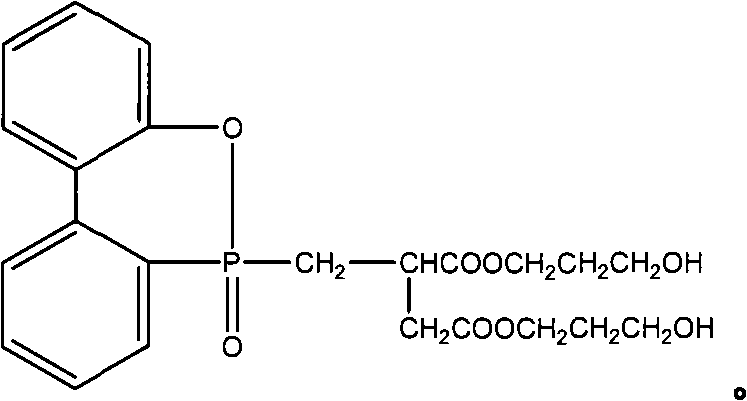

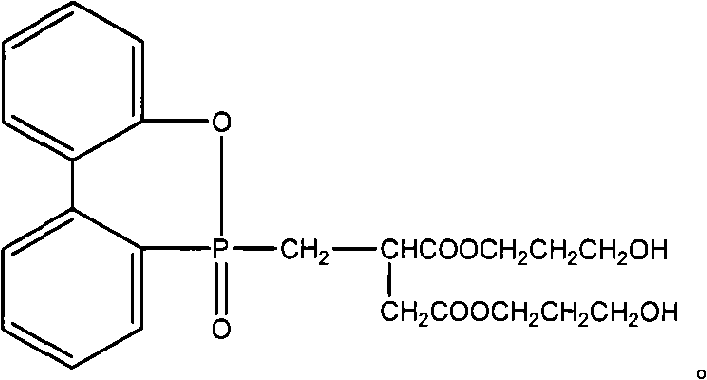

Image

Examples

Embodiment 1

[0030] According to the preparation method of the flame-retardant PTT polyester of the present embodiment, comprises the steps:

[0031] (1), the first esterification reaction: take 18kg of purified terephthalic acid (PTA), 8.4kg of 1.3-propylene glycol (PDO) in a molar ratio of 1:1.25 into a 70L polyester reactor, and add 0.2g of zinc acetate and stir After uniformity, start to heat up and pressurize to 0.15-0.30Mpa to carry out the esterification reaction. The esterification temperature is controlled at 220-260°C. After the esterification is completed and the water is discharged, return to normal pressure.

[0032] (2), the second esterification reaction: add 1.5LPDO to cool down in the reaction kettle through (1), make the temperature in the kettle drop to 220 ℃, mix the 2-carboxyethylphenylphosphinic acid prepared in advance with The mixed slurry 1250g (2-carboxyethylphenyl phosphinic acid 850g) of PDO is added, then implement normal pressure esterification, to the end of ...

Embodiment 2

[0035] According to the preparation method of the flame-retardant PTT polyester of the present embodiment, comprises the steps:

[0036] (1), the first esterification reaction: take 18kg of purified terephthalic acid (PTA), 8.4kg of 1.3-propanediol (PDO) in a molar ratio of 1:1.25 into a 70L reactor, and add 0.2g of zinc acetate and stir evenly , start to heat up and pressurize to 0.15-0.30Mpa to carry out the esterification reaction, the esterification temperature is controlled at 220-260°C, and return to normal pressure after the esterification is completed.

[0037] (2), the second esterification reaction: add 1.5LPDO to the reaction kettle that has passed through (1) to cool down, so that the temperature in the kettle is reduced to 220 ° C, and the pre-prepared 2-carboxyethylethylphosphonic acid and PDO 1250g of mixed slurry (containing 790g of 2-carboxyethylethylphosphonic acid) was added, and then the normal pressure esterification was carried out until the esterificatio...

Embodiment 3

[0040] According to the preparation method of the flame-retardant PTT polyester of this embodiment, the difference is that in this example, the phosphorus-based copolymerized flame retardant used is 1380g of the flame retardant and 870g of PDO are made into a mixed slurry and added to the reaction kettle passing through (1), and the ethylene glycol preparation solution of the inorganic nanomaterial barium sulfate is 2.0% of the total amount of the chips. After the polymerization is complete, the pellets are cut and tested. The slice index is shown in Table 1. Slice limiting oxygen index: 29.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com