Improved automatic control hydraulic drive oil pumping machine

A technology of hydraulic transmission and pumping unit, which is applied in transmission devices, fluid transmission devices, mechanical equipment, etc., can solve the problems of low service life of seals, large area of hydraulic cylinders, and unsatisfactory energy-saving effect, and achieves the improvement of mechanical Performance, safe and reliable performance, good energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

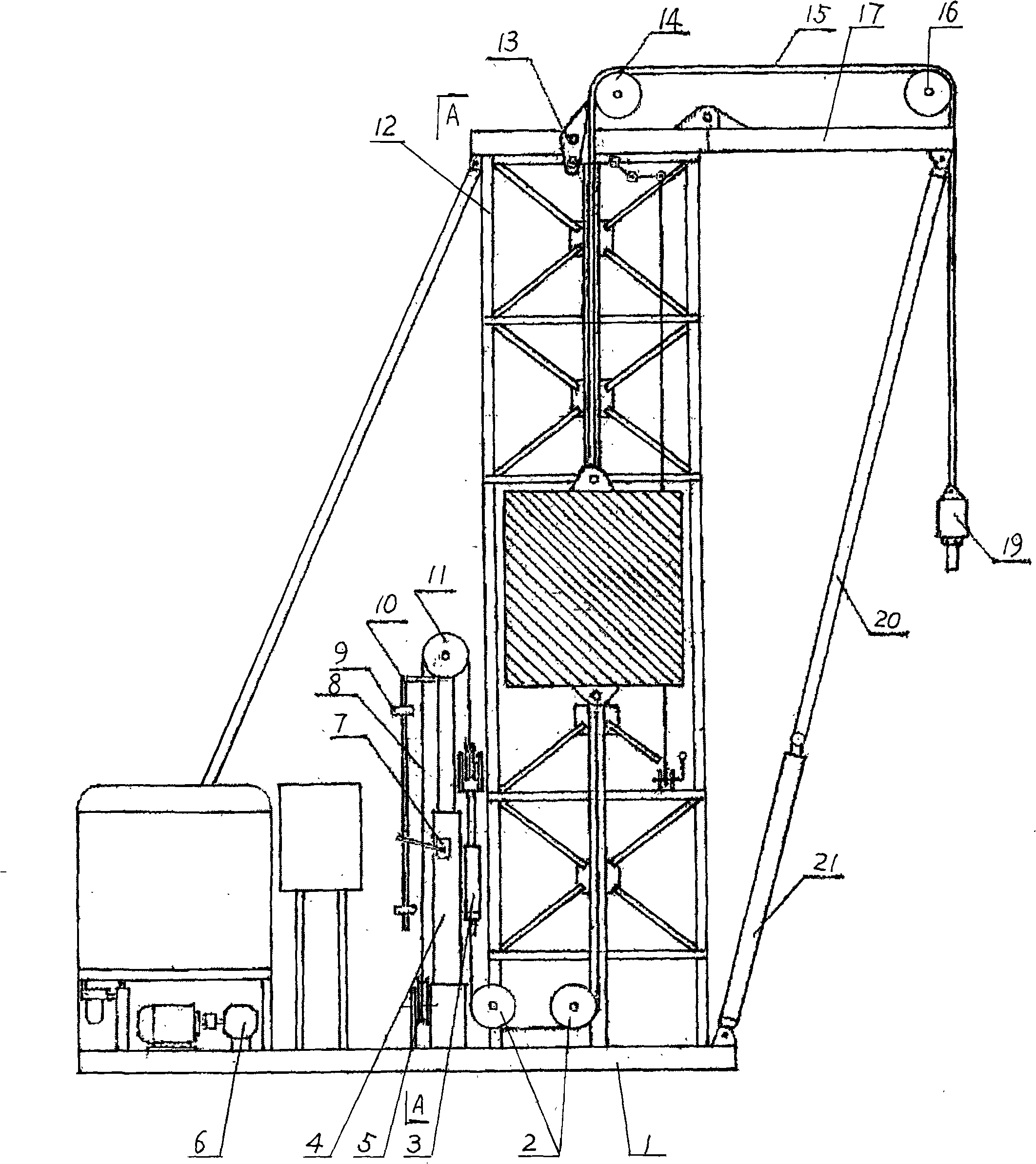

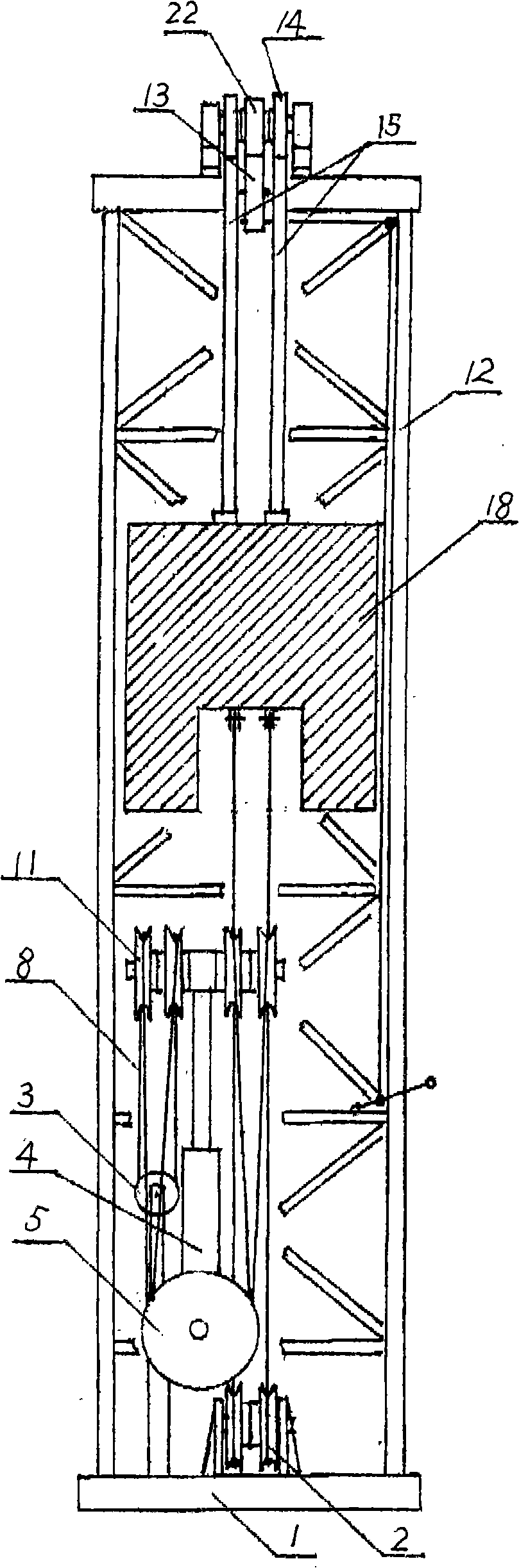

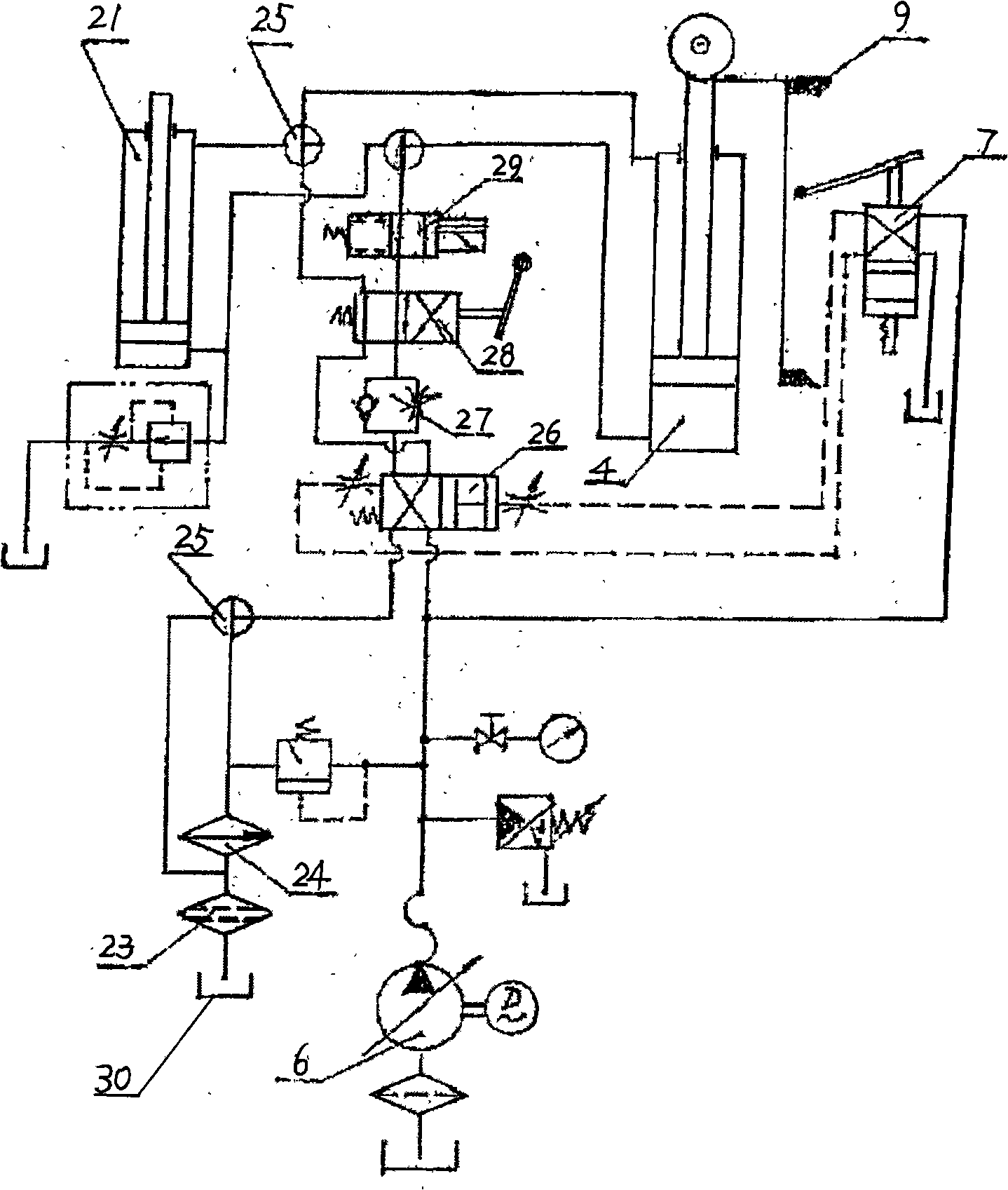

[0010] An improved automatic control hydraulic transmission pumping unit, such as figure 1 , figure 2 , image 3 As shown, it includes a hydraulic cylinder installed on the hydraulic circuit and a motorized reversing valve 7 is arranged on the hydraulic cylinder 4, and a symmetrical stroke adjustment block 9 is arranged on the stroke controller 10 installed at the end of the piston rod of the hydraulic cylinder 4 , the control arm of the motorized reversing valve 7 cooperates with the symmetrical block 9, and the upright hydraulic cylinder 4 and the support frame 12 are fixed on the machine base 1, the movable pulley 11 is installed on the top of the piston rod of the hydraulic cylinder 4, and the support frame 12 The sprocket wheel 14 with safety locking device is installed on the upper platform. The safety locking device is a ratchet mechanism, and a ratchet 22 is fixed on the sprocket shaft, and the ratchet 13 installed on the platform on the support frame 12 cooperates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com