Cellulose acetate prepared by taking cotton linter pulp as raw material and preparation method and application thereof

A technology of cellulose acetate and cotton linter pulp, which is applied in the field of cellulose acetate made from cotton linter pulp and its manufacture and application, and can solve the problem of high crystallinity of cotton linter pulp and difficult acetylation process. Control, low production efficiency and other issues, to achieve the effect of good product quality, simple manufacturing method, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

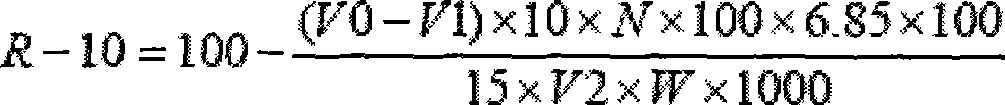

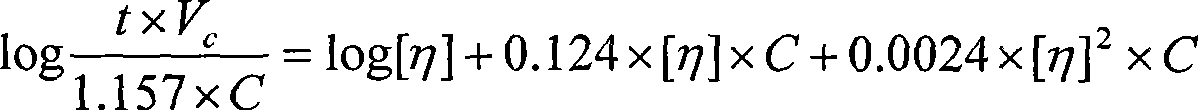

[0042] Using cotton linter pulp with 85.6% R-10 and a viscosity of 5.7dl / g as raw material, cellulose acetate was prepared through the following process:

[0043] (1) Cotton linter pulp crushing: the plate-shaped cotton linter pulp finished product is crushed into a fluffy appearance through a grinder.

[0044] (2) Activation: Spray acetic acid on the pulverized cotton linter pulp. The consumption of acetic acid is 80% of cotton linter pulp weight, and the temperature of activation is 25 ℃, and activation time is 100 minutes.

[0045] (3) acetylation: taking the cotton linter pulp weight as a benchmark, 300% acetic acid, 18% sulfuric acid, 200% acetic anhydride and cotton linter pulp are added in the esterification reactor, and the initial temperature of the reaction is from Starting at -10°C, the temperature rise rate was controlled at 1°C / min, and the acetylation reaction time was 80 minutes.

[0046] (4) Hydrolysis: a magnesium acetate aqueous solution with a mass concent...

Embodiment 2

[0052] Using cotton linter pulp with 99.1% R-10 and a viscosity of 8.2dl / g as raw material, cellulose acetate was prepared through the following process:

[0053] (1) Cotton linter pulp crushing: the flocculent cotton linter pulp finished product is crushed into a fluffy appearance through a grinder.

[0054] (2) Activation: Spray acetic acid on the pulverized cotton linter pulp. The consumption of acetic acid is 18% of cotton linter pulp weight, and the temperature of activation is 30 ℃, and activation time is 50 minutes.

[0055] (3) acetylation: taking the cotton linter pulp weight as a basis, 300% acetic acid, 8% sulfuric acid, 220% acetic anhydride and cotton linter pulp are added in the esterification reactor, and the initial temperature of the reaction is from Starting at 0°C, the temperature rise rate was controlled at 0.85°C / min, and the acetylation reaction time was 96 minutes.

[0056] (4) Hydrolysis: use a magnesium acetate aqueous solution with a mass concentrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com