Relief printing plate precursor for laser engraving, relief printing plate, and method of manufacturing relief printing plate

A technology of laser engraving and printing plate, applied in the preparation of printing surface, printing, printing process, etc., to achieve the effect of high engraving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

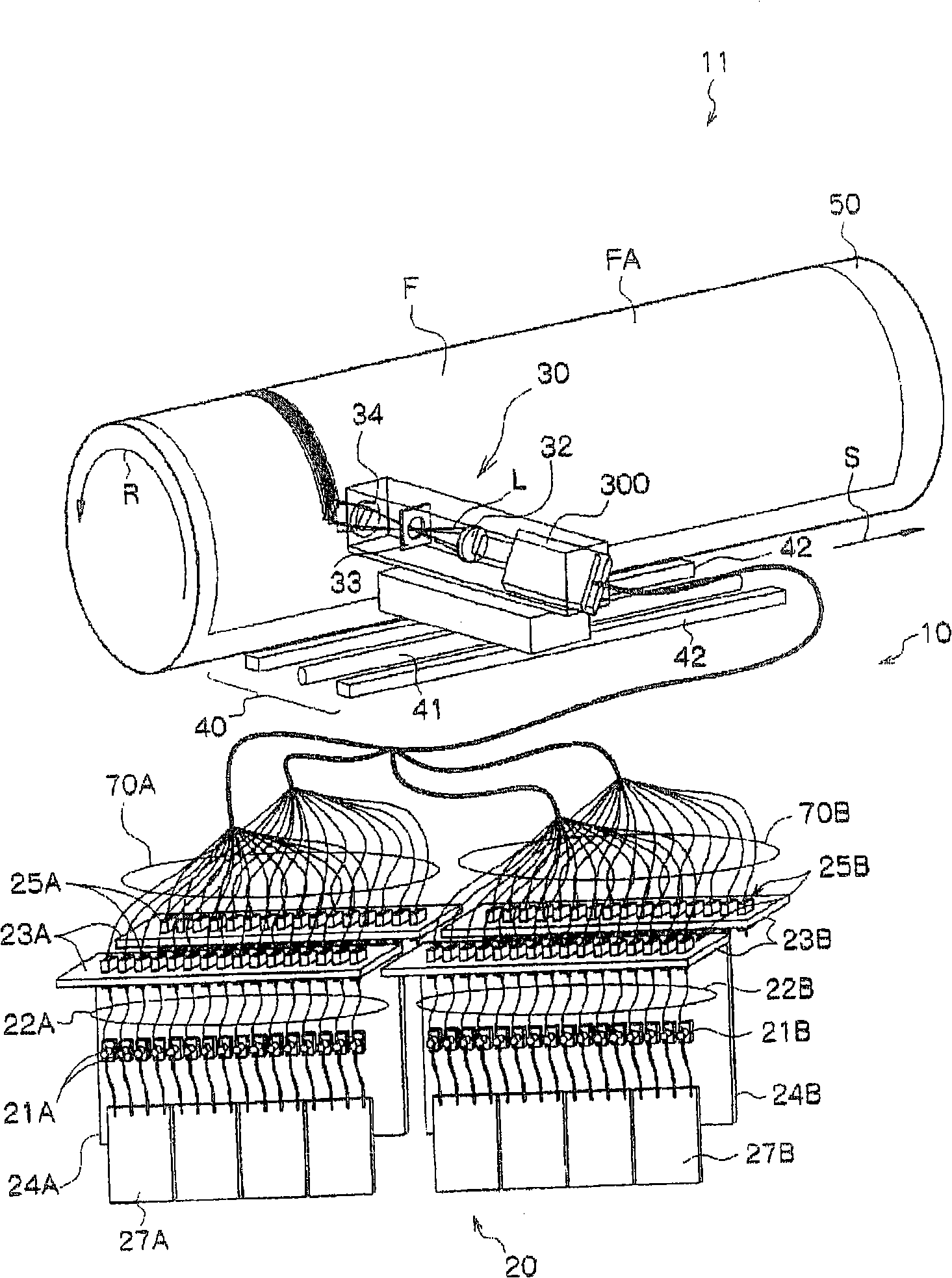

Image

Examples

Embodiment 1

1. Preparation of crosslinkable resin composition for laser engraving

In a three-necked flask equipped with a stirring blade and a cooling tube, 50 parts by mass of polyvinyl butyral (trade name: BL-1, manufactured by Sekisui Chemical Co., Ltd.) as the specific polymer (A) was charged. , Mw: 19,000), 1 part by mass of carbon black (trade name: KETJENBLACK EC600JD, manufactured by Lion Corporation) as a light-to-heat conversion agent (E), 20 parts by mass of diethylene glycol as a plasticizer, and 47 parts by mass of ethanol, and heated at 70° C. for 120 min while stirring to dissolve the specific polymer (A). Further, the resultant was cooled to 40° C., and 15 parts by mass of ethylenically unsaturated monomer M-1 having the structure shown below, 13 parts by mass of hydroxyethyl (meth)acrylate (trade name; BLEMMER PME200 , manufactured by NOF Corp.) and 1 mass part of tert-butyl peroxybenzoate (t-butyloxybenzoate) (trade name: PERBUTYLZ, manufactured by NOF Corp.) as a polym...

Embodiment 2 to 17 and comparative example 1 to 8

1. Preparation of crosslinkable resin composition for laser engraving

Coating solutions (crosslinkable resin compositions for laser engraving) of Examples 2 to 17 and Comparative Examples 1 to 8 for forming a crosslinkable relief-forming layer were prepared in the same manner as in Example 1, respectively, with different The point is that, as shown in Tables 4 and 5 below, Specific Polymers 2 to 14 and Comparative Polymers C-1 to C-6 were used instead of BL-1 (as described above) as Specific Polymer (A), respectively. , and the polymerizable compound (C), polymerization initiator (D) and light-to-heat conversion agent (E) were changed as shown in the following Tables 4 and 5, respectively.

[0327] Details of the specific polymer (A) and the comparative binder polymer used in Examples and Comparative Examples are as follows.

Specific polymer 2: polyvinyl butyral (Mw: 66000) (trade name: BH-S, manufactured by Sekisui Chemical Co., Ltd.)

Specific polymer 3: polyvinyl butyral (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com