A method for wet phosphoric acid producing high pure calcium hydrogen orthophosphate

A technology of wet-process phosphoric acid and calcium hydrogen phosphate, which is applied in the direction of chemical instruments and methods, phosphate, phosphorus oxyacids, etc., can solve the problems of low effective phosphorus content, heavy pollution, and large phosphorus loss in by-product phosphate fertilizers, and achieve effective Effect of high phosphorus content, high total calcium and phosphorus content, and less phosphorus loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

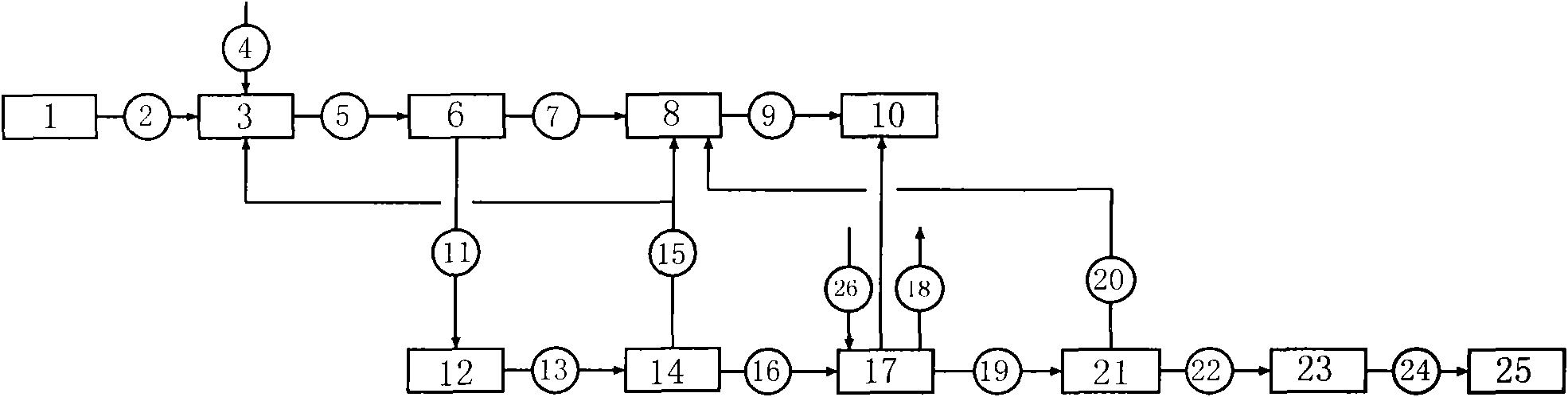

[0037] 26%P 2 o 5Wet-process phosphoric acid 2 is fed into the ammoniation tank 3 at a rate of 13.9t / h, and ammonia 4 is added at a rate of 0.87t / h at the same time. The ammoniation aging temperature is 100°C, the pH value of the ammoniation slurry is 4.0, and the reaction and aging time is 1 day. The aged ammoniated slurry 5 is deaminated by the slurry filter 6. After being filtered and separated by the rotary drum vacuum filter, the filter residue 7 enters the drying device 8, and the drum dryer is used, and the air temperature at the inlet of the dryer is controlled to be 200~ 250°C, the outlet air temperature is 100-120°C, after drying and packaging, fertilizer-grade monoammonium phosphate is obtained; the filtrate is evaporated and crystallized 12 to obtain monoammonium phosphate crystals, 40% of the monoammonium phosphate filtrate 15 (volume%, hereinafter the same ) returns to the ammoniation tank 3, and 60% goes to the drying device 8; the monoammonium phosphate cryst...

Embodiment 2

[0039] 15%P 2 o 5 Content Wet-process phosphoric acid 2 is fed into ammoniation tank 3 at a rate of 24.1t / h, and ammonia 4 is added at a rate of 0.95t / h at the same time. The ammoniation aging temperature is 60°C, the pH value of the ammoniation slurry is 6.8, and the reaction and aging time is 0.5 days. The aged ammoniated slurry 5 is deaminated by the slurry filter 6. After being filtered and separated by the rotary drum vacuum filter, the filter residue 7 enters the drying device 8, and the drum dryer is used, and the air temperature at the inlet of the dryer is controlled to be 200~ 250°C, the outlet air temperature is 100-120°C, after drying and packaging, fertilizer-grade monoammonium phosphate is obtained; the filtrate is evaporated and crystallized 12 to obtain monoammonium phosphate crystals, and 50% of the monoammonium phosphate filtrate 15 is returned to the ammoniation tank 3, 50% to the drying device 8; the monoammonium phosphate crystal enters the neutralizatio...

Embodiment 3

[0041] 46%P 2 o 5 Content Wet-process phosphoric acid 2 is fed into ammoniation tank 3 at a rate of 7.86t / h, and ammonia 4 is added at a rate of 0.85t / h at the same time. The ammoniation aging temperature is 110°C, the pH value of the ammoniation slurry is 3.8, and the reaction and aging time is 5 days. The aged ammoniated slurry 5 is deaminated by the slurry filter 6. After being filtered by a plate and frame filter press, the filter residue 7 enters the drying device 8. A drum dryer is used to control the air temperature at the inlet of the dryer to 200-250 ℃, the outlet air temperature is 100-120 ℃, after drying and packaging, fertilizer-grade monoammonium phosphate is obtained; the filtrate is evaporated and crystallized 12 to obtain monoammonium phosphate crystals, and 20% of the monoammonium phosphate filtrate 15 is returned to the ammoniation tank 3,80 % go to the drying device 8; the monoammonium phosphate crystal enters the neutralization tank 17 after being centrif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com