Immersion type hollow fibre membrane assembly with air vents

A technology of fiber membranes and air guide holes, which is applied in membrane technology, semi-permeable membrane separation, water/sludge/sewage treatment, etc. It can solve the problems that the upper sludge cannot be discharged smoothly, the service life of components is reduced, and the membrane filaments are fatigued and damaged. , to achieve the effect of good pollution removal, prolong service life and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

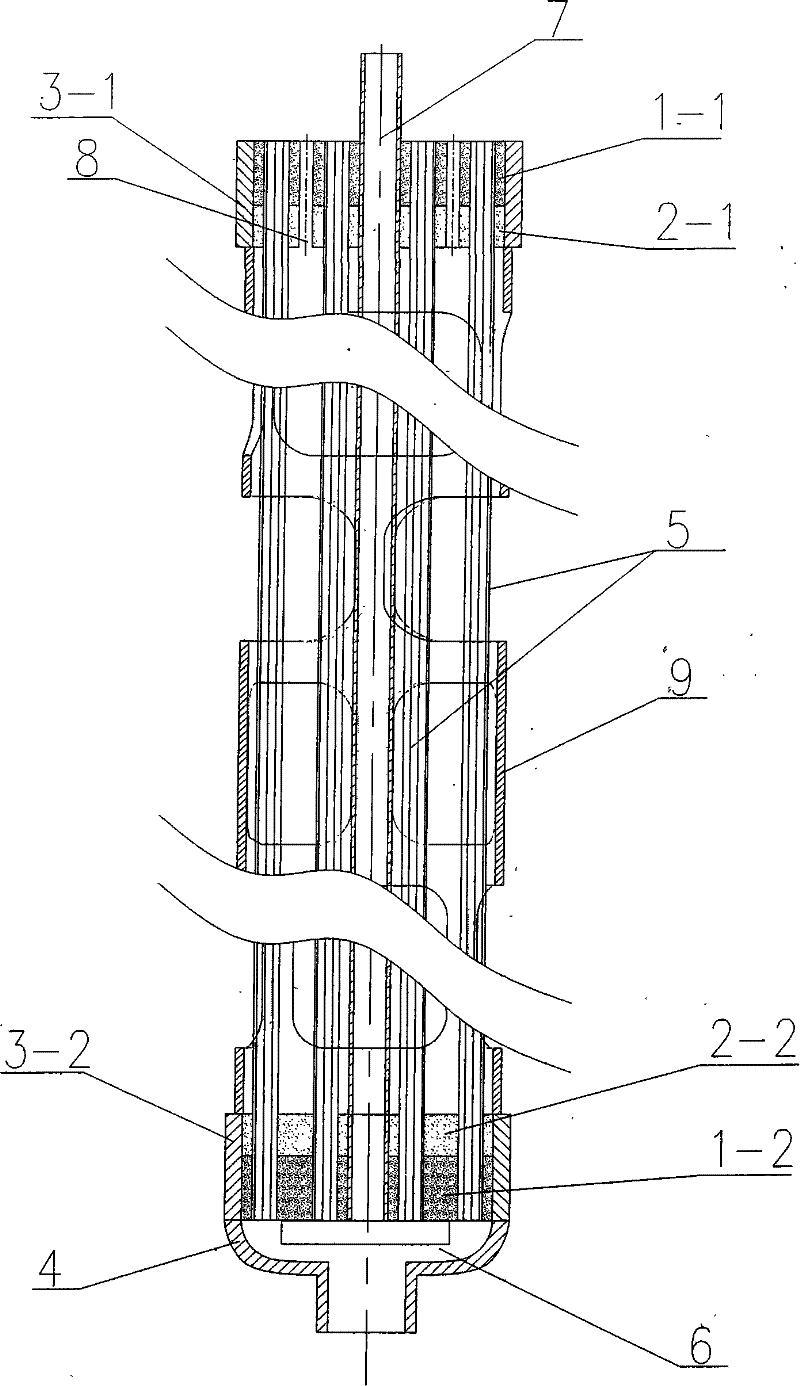

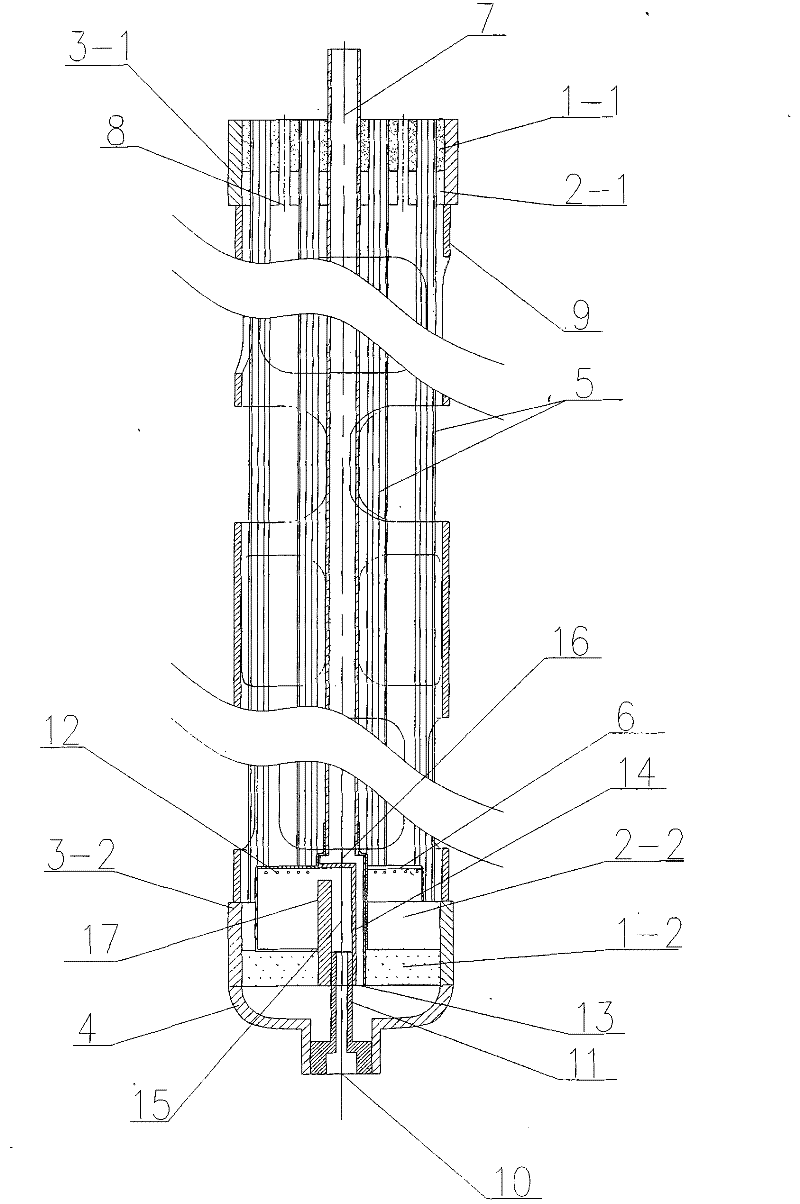

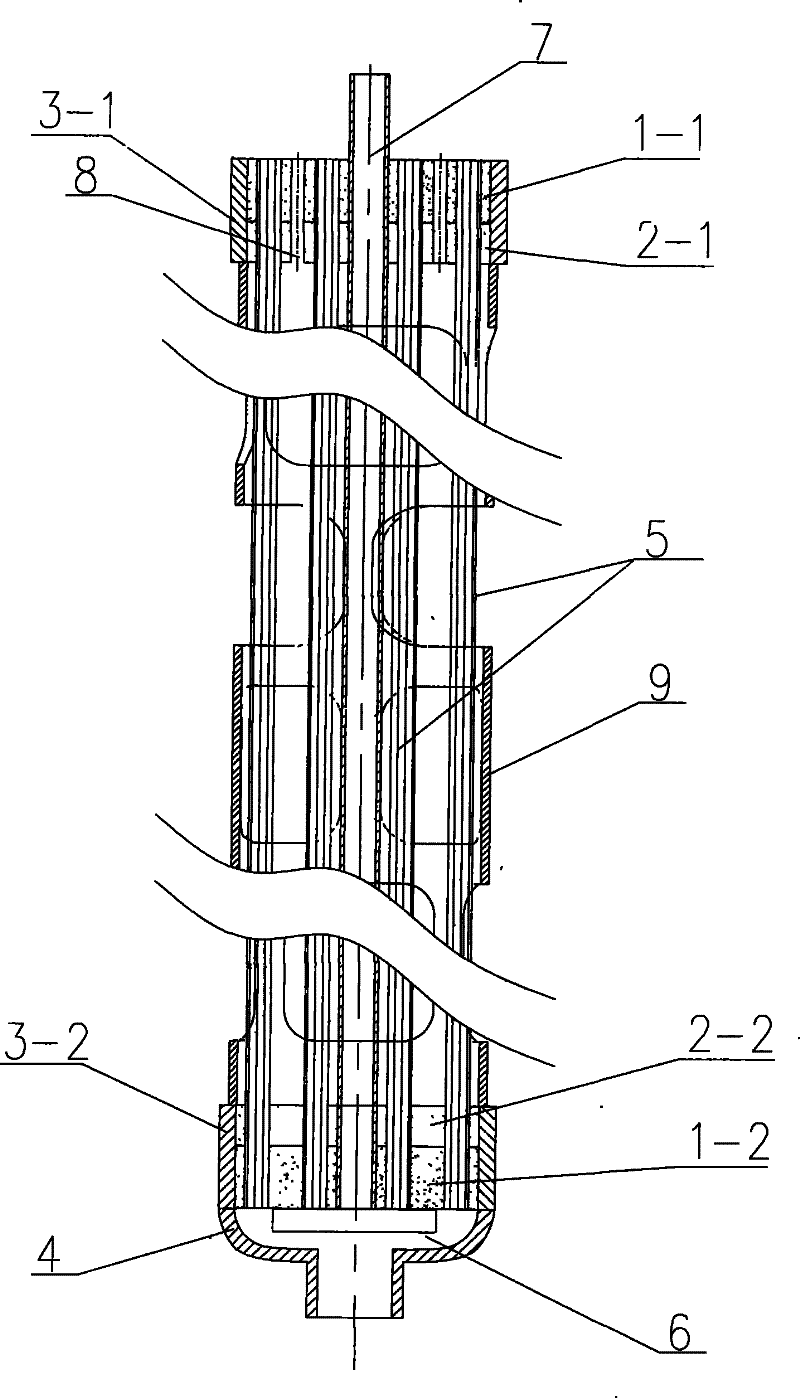

[0019] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0020] The submerged membrane module of the present invention is an improvement on the basis of the existing membrane module. Contamination at the top of the wire. At the same time, the lower end produces water and aeration. The water produced at the lower end of the component is communicated with the water production pipeline at the upper end of the component through the water collection pipe. To this end, two arrangements of water collection pipes are designed. One is that the water collecting pipe is opened on the outer end surface of the lower resin fixing layer, and the other is that a specific aeration device is used to communicate with the water collecting pipe.

[0021] The structural schematic diagram of the submerged membrane module with air guide holes in which the water collecting pipe is opened on the outer end face of the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com