Backlight of light-emitting diodes

A light-emitting diode and backlight technology, which is applied in the field of backlight, can solve problems such as the thickening of the backlight structure, and achieve the effects of improving brightness, improving heat dissipation performance, and increasing heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The first solution of the LED backlight source of the present invention

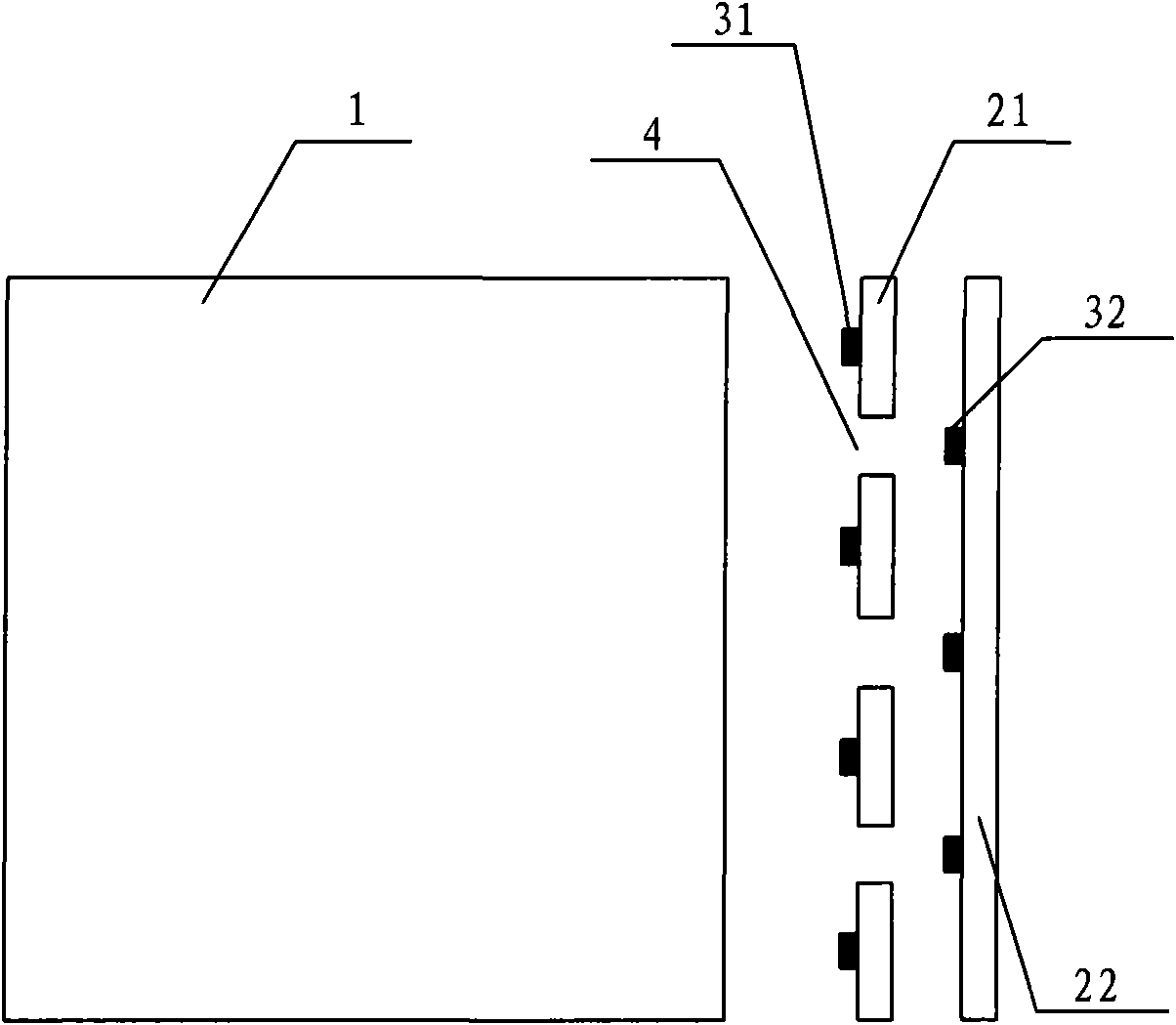

[0029] figure 1 It is a schematic diagram of the structure of the first solution of the LED backlight of the present invention, such as figure 1 As shown, the LED backlight of this solution includes a first circuit board 21, a second circuit board 22, a plurality of first LEDs 31 and a plurality of second LEDs 32, and the light guide plate 1 is located on one side of the first circuit board 21 Several first light-emitting diodes 31 are uniformly fixed on the first circuit board 21, a light-transmitting hole 4 is opened between two adjacent first light-emitting diodes 31, and the second circuit board 22 is arranged in parallel on the first circuit board 21 On the other side, several second LEDs 32 are evenly fixed on the second circuit board 22, and the position of each second LED 32 corresponds to the position of the light-transmitting hole 4 on the first circuit board 21, so that the second The li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com