Marginal ring mechanism used in semiconductor manufacture technology

A manufacturing process and edge ring technology, used in semiconductor/solid-state device manufacturing, plasma, electrical components, etc., can solve problems such as high practicability, achieve simple processing, improve particle pollution problems, and facilitate installation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

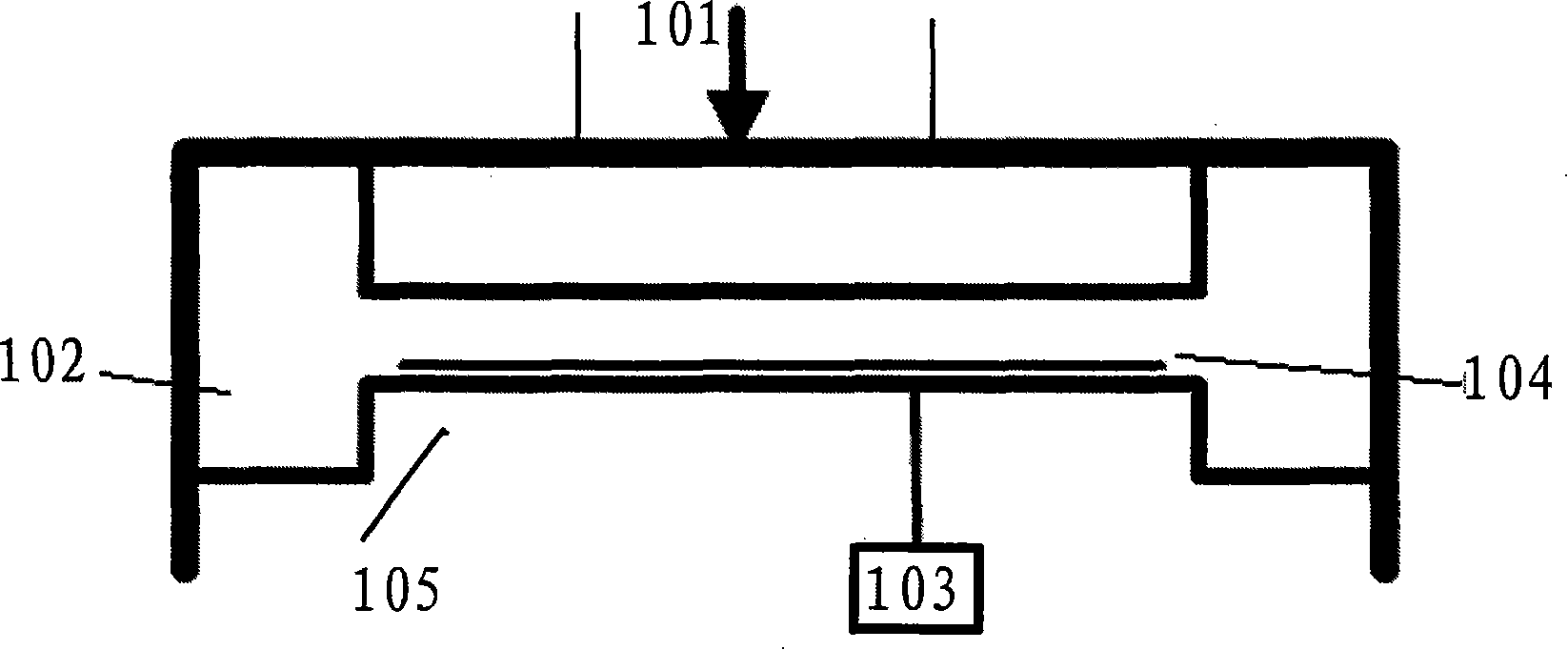

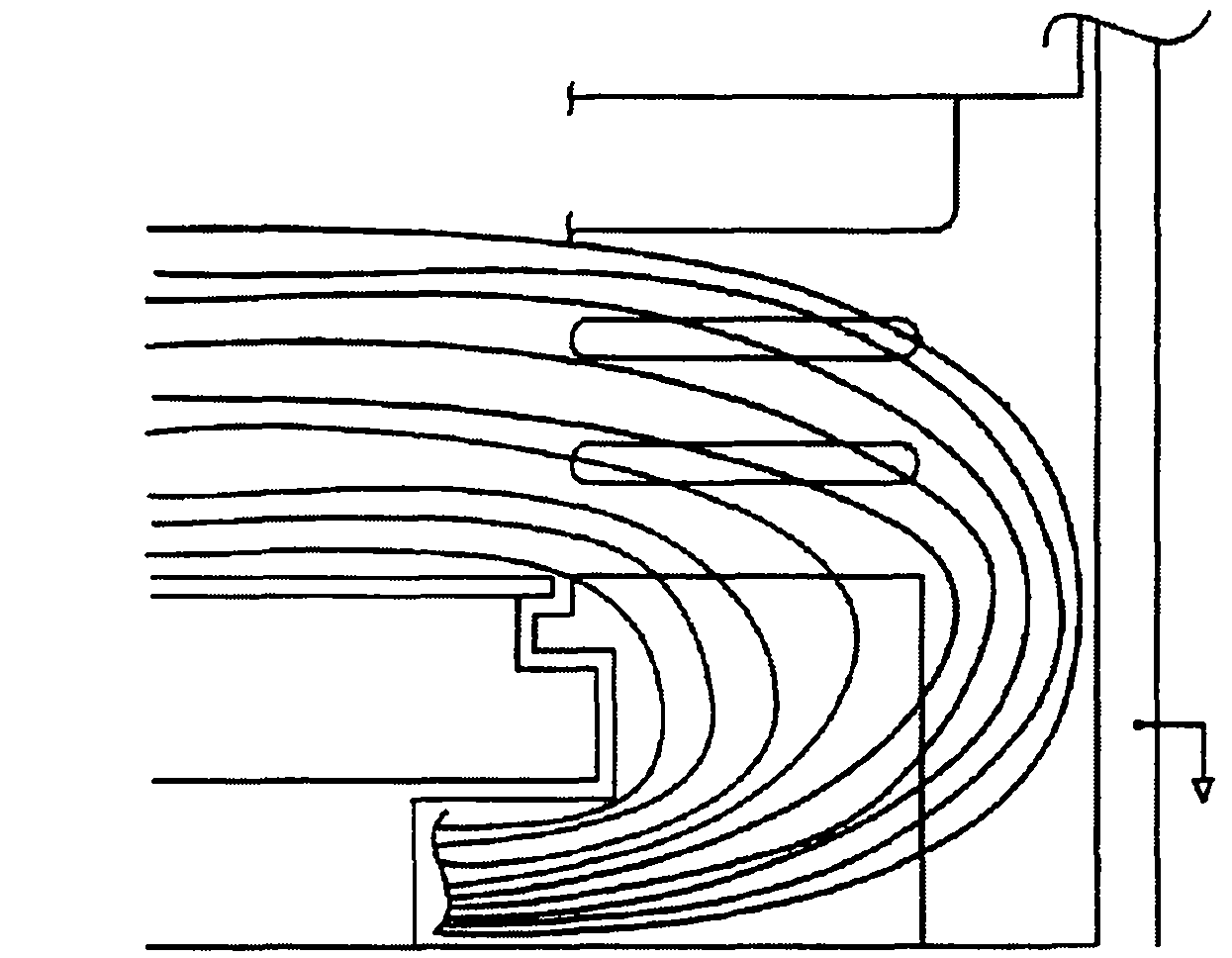

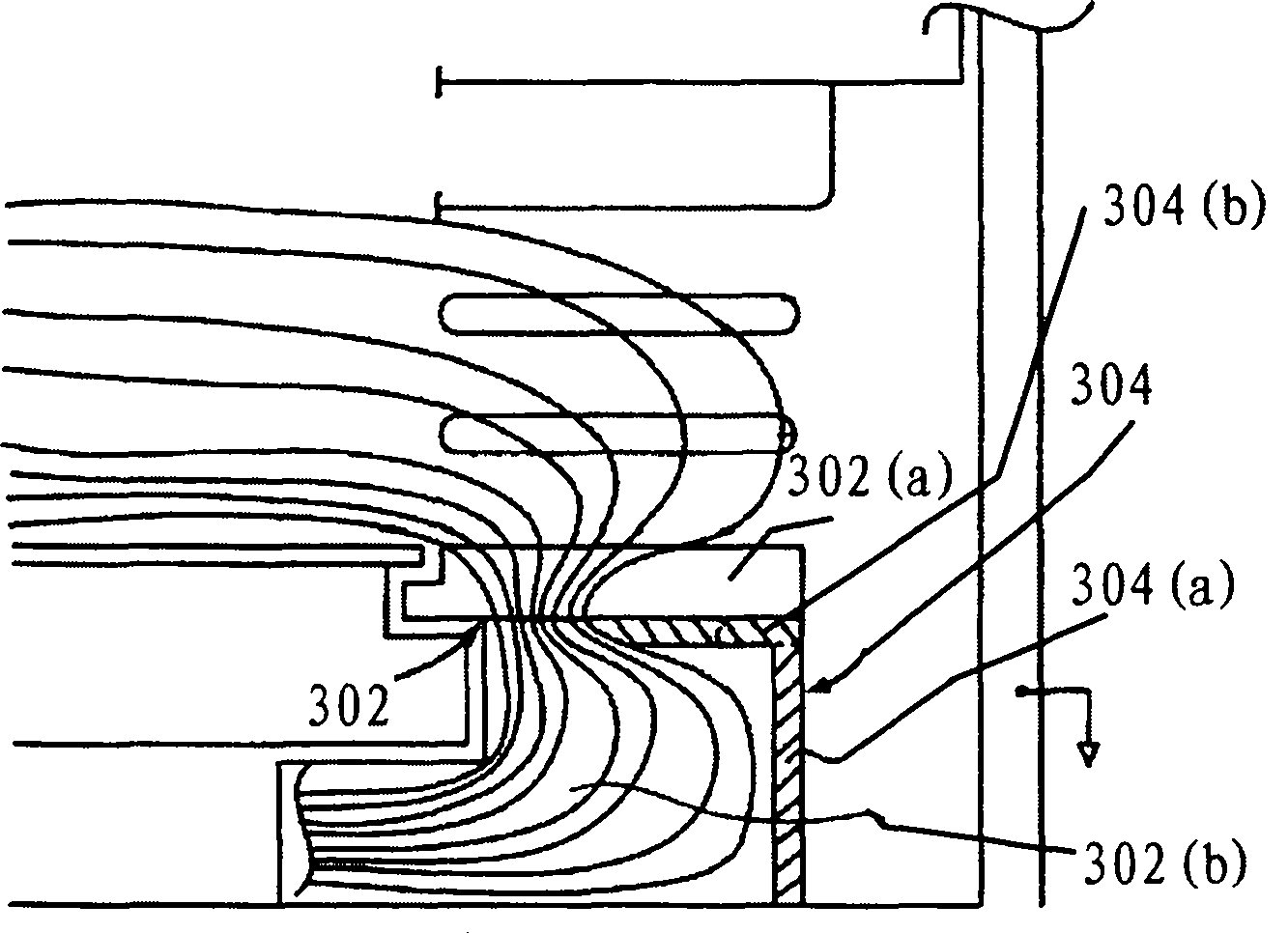

[0034] see Figure 4a ~ Figure 6b , which shows a preferred embodiment of an edge ring mechanism used in a semiconductor manufacturing process of the present invention, including an electrostatic chuck 41 for fixing a wafer 1, and a lower electrode base 42 is provided below the electrostatic chuck 41, and in said An edge ring 2 is arranged around the electrostatic chuck 41, and a gap 24 is provided between the edge ring 2 and the electrostatic chuck 41. The gap 24 can be used to prevent the thermal expansion coefficient between the edge ring 2 and the wafer 1. The damage that may be caused by the difference can also be used as a section of gas circulation channel, which is preferably a temperature-regulated gas circulation channel; a gas channel 21 is opened on the lower electrode base 42, and a gas channel 21 is opened on the edge ring 2 A gas circulation channel connecting the gap 24 and the gas channel 21 is provided on the top, preferably a temperature-adjusting gas circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com