Solar panel with improved heat radiation performance

A technology for solar panels and solar cells, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as increasing the cost of solar panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

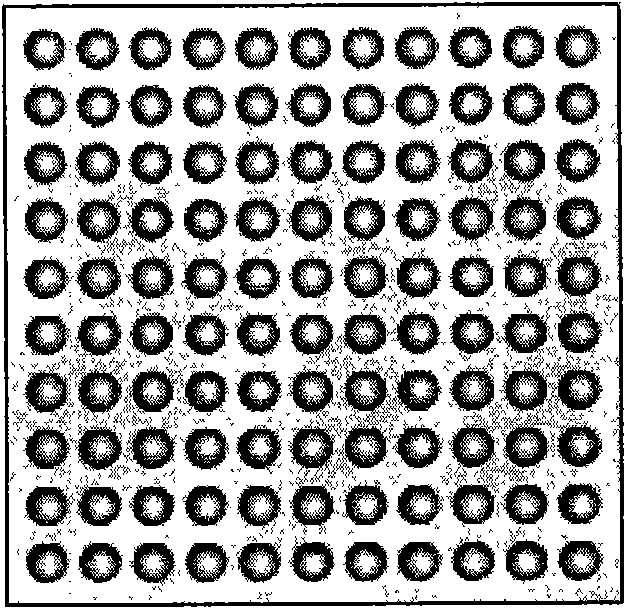

[0110] This embodiment illustrates the heat dissipation effect of the solar cell panel on the back plate with square-arranged spherical protrusions used in the present invention.

[0111] like Figure 21 As shown, the solar cell in this example consists of three parts: the front plate (tempered glass, purchased from Dongguan CSG Solar Glass Co., Ltd., 3.2 mm thick), the polysilicon solar cell circuit (125×125×0.3 mm, 72 pieces connected in series) and the back plate. composition. The backsheet is a laminated film consisting of two 25-micron thick polyvinyl fluoride films ( PV2001, a layer of thick polytrimethylene terephthalate film ( DuPont Company of the United States), and formed by hot pressing under vacuum conditions. After these three parts are hot-pressed together with two layers of ethylene-vinyl acetate copolymer (Ruifu brand photovoltaic cell EVA film, R767, purchased from Wenzhou Ruiyang Photovoltaic Material Co., Ltd.) with a thickness of 700 microns, The sid...

Embodiment 2

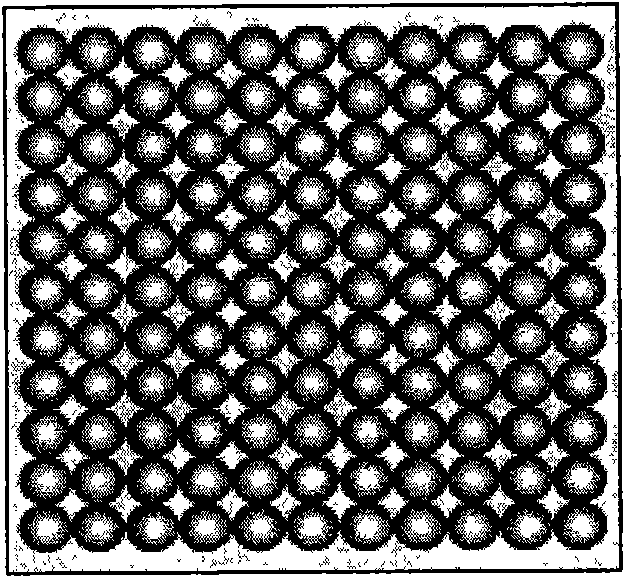

[0116] This embodiment illustrates the heat dissipation effect of the solar cell panel on the back plate with spherical protrusions closely arranged in four directions used in the present invention.

[0117] like Figure 21 As shown, the solar cell in this example consists of three parts: the front plate (tempered glass, purchased from Dongguan CSG Solar Glass Co., Ltd., 3.2 mm thick), the polysilicon solar cell circuit (125×125×0.3 mm, 72 pieces connected in series) and the back plate. composition. The backsheet is a laminated film consisting of two 25-micron thick polyvinyl fluoride films ( PV2001, a layer of thick polytrimethylene terephthalate film ( DuPont Company of the United States), and formed by hot pressing under vacuum conditions. The three parts were hot-pressed together with two layers of ethylene-vinyl acetate copolymer (Ruifu brand photovoltaic cell EVA adhesive film, R767, purchased from Wenzhou Ruiyang Photovoltaic Material Co., Ltd.) with a thickness of ...

Embodiment 3

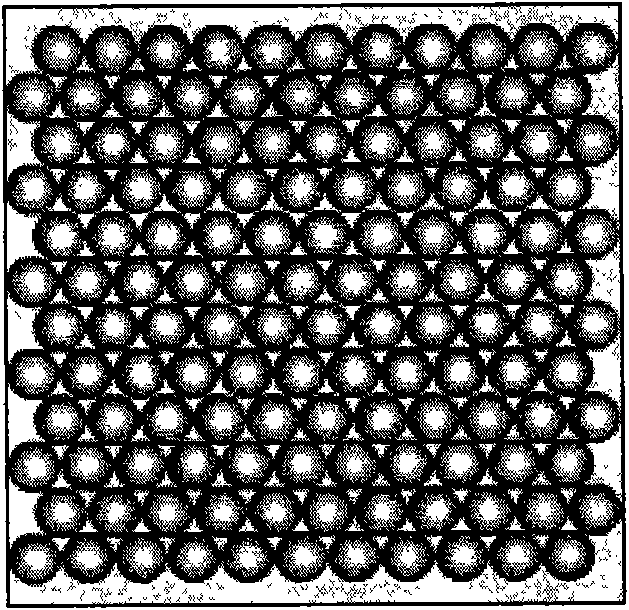

[0120] This embodiment illustrates the heat dissipation effect of the solar cell panel on the back plate with hexagonal closely arranged spherical protrusions used in the present invention.

[0121] like Figure 21 As shown, the solar cell in this example consists of three parts: the front plate (tempered glass, purchased from Dongguan CSG Solar Glass Co., Ltd., 3.2 mm thick), the polysilicon solar cell circuit (125×125×0.3 mm, 72 pieces connected in series) and the back plate. composition. The backsheet is a laminated film consisting of two 25-micron thick polyvinyl fluoride films ( PV2001, a layer of thick polytrimethylene terephthalate film ( DuPont Company of the United States), and formed by hot pressing under vacuum conditions. The three parts were hot-pressed together with two layers of ethylene-vinyl acetate copolymer (Ruifu brand photovoltaic cell EVA adhesive film, R767, purchased from Wenzhou Ruiyang Photovoltaic Material Co., Ltd.) with a thickness of 700 micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com