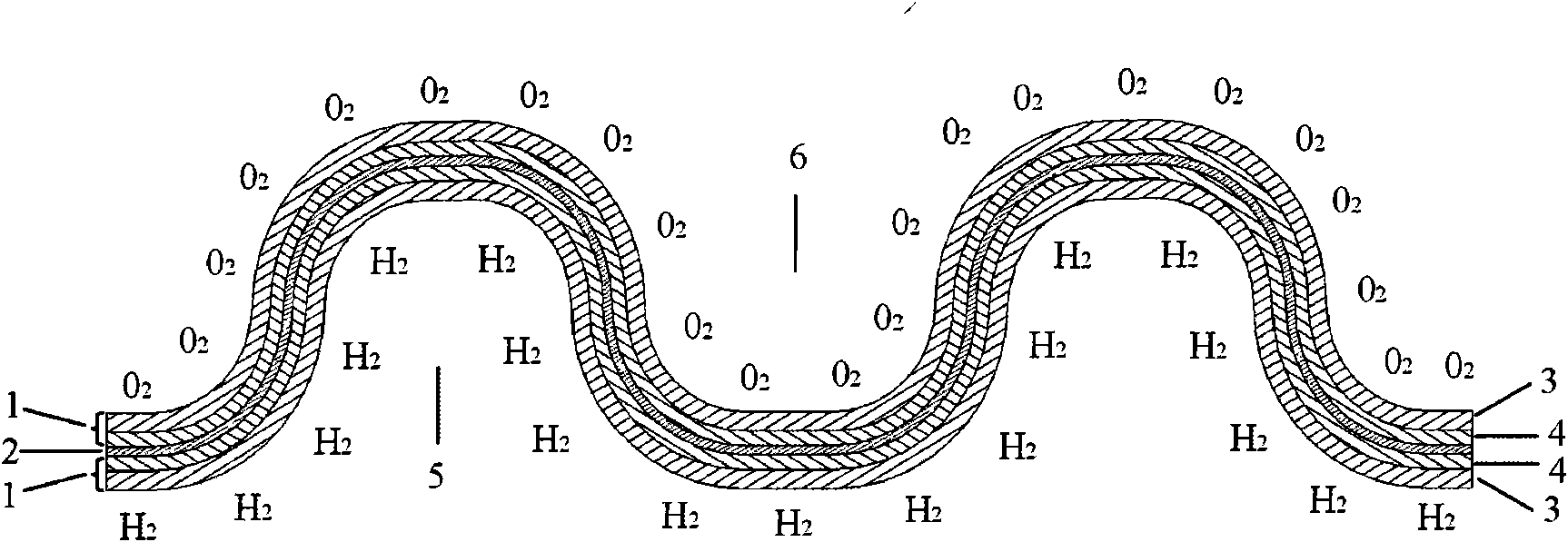

Method of compositely manufacturing proton exchange membrane fuel cell bipolar plate and membrane electrode assembly

A proton exchange membrane and membrane electrode assembly technology, which is applied to fuel cell parts, fuel cells, battery electrodes, etc., can solve the problems of high contact resistance of metal bipolar plates, easy rupture of gas diffusion layers, and inability to bend and form. Achieve the effect of reducing ohmic loss, reducing processing cost, and eliminating contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment is implemented under the following conditions of implementation and technical requirements:

[0032]The double-layer stainless steel 316 fiber mesh is processed into a bipolar plate 1 by a stamping forming process. The formed electrode plate 1 is removed by an alkali washing-acid washing-water washing process to remove surface grease and oxide film. The pretreated bipolar plate 1 is first weighed, and then dipped in polytetrafluoroethylene emulsion with a concentration of 5% for several times for water-repellent treatment. Take out the soaked PTFE bipolar plate and dry it in the shade, then place it in an oven at a temperature of 330°C to 340°C and bake it to remove the surfactant contained in the PTFE emulsion impregnated in the fiber net, and at the same time make the Polytetrafluoroethylene is hot-melt and sintered and evenly dispersed on the fiber, so as to achieve a good water-repellent effect and build a gas channel that is conducive to gas transm...

Embodiment 2

[0037] This embodiment is implemented under the following conditions of implementation and technical requirements:

[0038] The double-layer stainless steel 316 fiber mesh is processed into a bipolar plate 1 by a stamping forming process. The formed electrode plate 1 is removed by alkali washing-acid washing-water washing process to remove surface grease and oxide film. The pretreated bipolar plate 1 is first weighed, and then dipped in polytetrafluoroethylene emulsion with a concentration of 5% for several times for water-repellent treatment. Take out the soaked PTFE bipolar plate and dry it in the shade, then place it in an oven at a temperature of 330°C to 340°C and bake it to remove the surfactant contained in the PTFE emulsion impregnated in the fiber net, and at the same time make the Polytetrafluoroethylene is hot-melt and sintered and evenly dispersed on the fiber, so as to achieve a good water-repellent effect and build a gas channel that is conducive to gas transmis...

Embodiment 3

[0044] This embodiment is implemented under the following conditions of implementation and technical requirements:

[0045] The double-layer stainless steel 316 fiber mesh is processed into a bipolar plate 1 by a stamping forming process. The formed electrode plate 1 is removed by alkali washing-acid washing-water washing process to remove surface grease and oxide film. The pretreated bipolar plate 1 is first weighed, and then dipped in polytetrafluoroethylene emulsion with a concentration of 5% for several times for water-repellent treatment. Take out the soaked PTFE bipolar plate and dry it in the shade, then place it in an oven at a temperature of 330°C to 340°C and bake it to remove the surfactant contained in the PTFE emulsion impregnated in the fiber net, and at the same time make the Polytetrafluoroethylene is hot-melt and sintered and evenly dispersed on the fiber, so as to achieve a good water-repellent effect and build a gas channel that is conducive to gas transmis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com