Electrolysis water generator and using method thereof

An electrolytic water maker and electrolytic electrode technology, which are applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of increased concentration, complicated structure, restricted popularization and promotion, etc. The effect of reduced failure rate, simplified structure and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

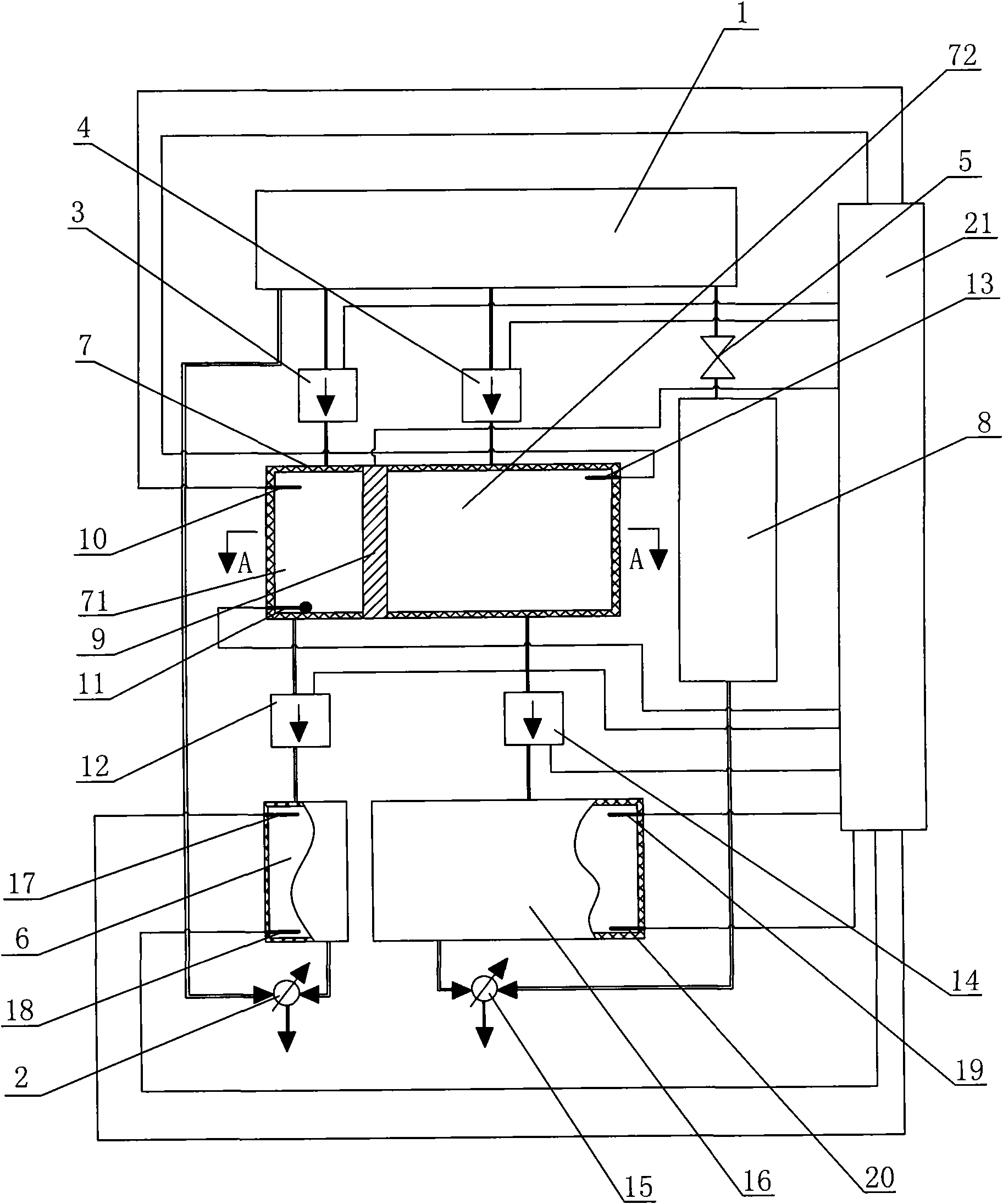

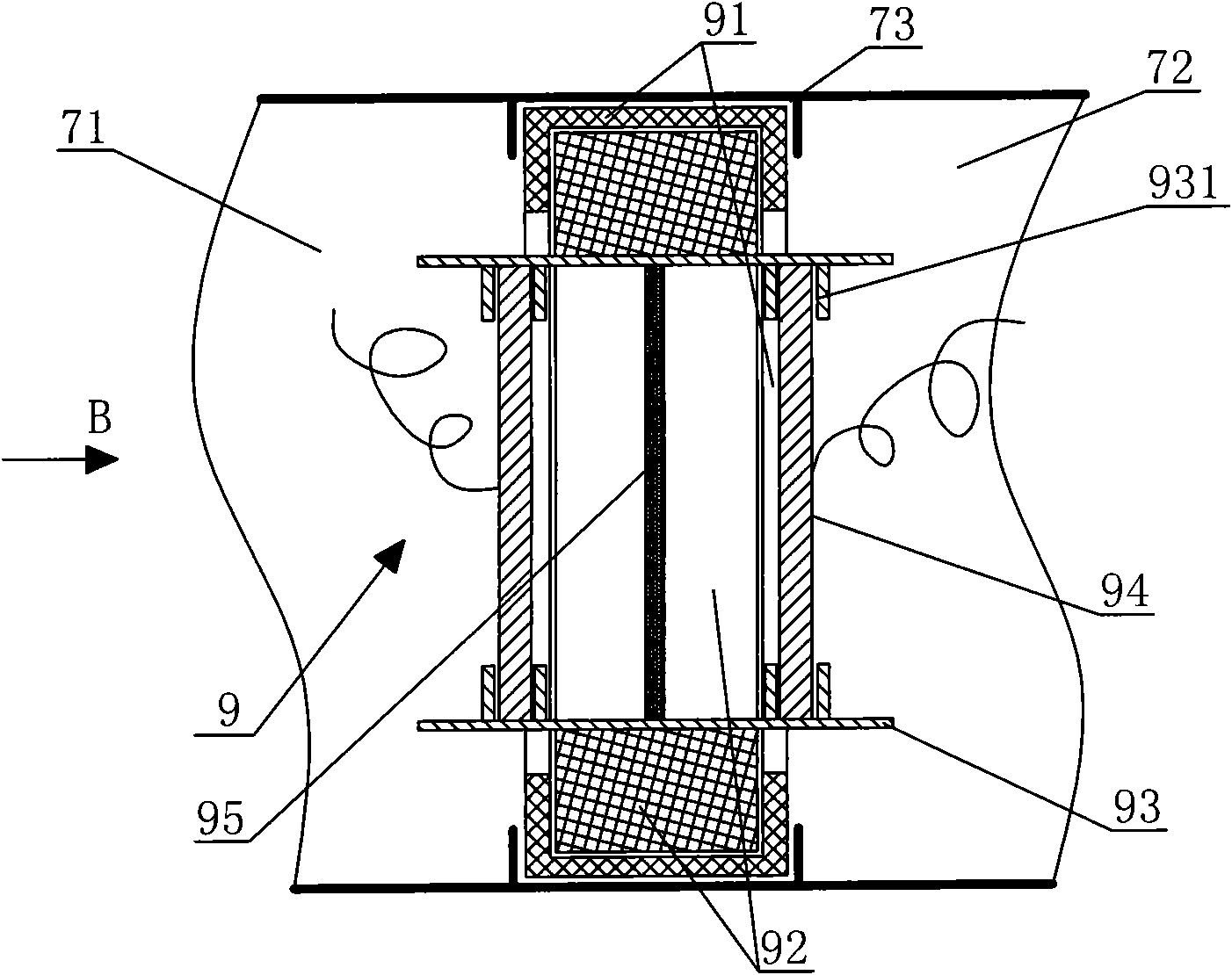

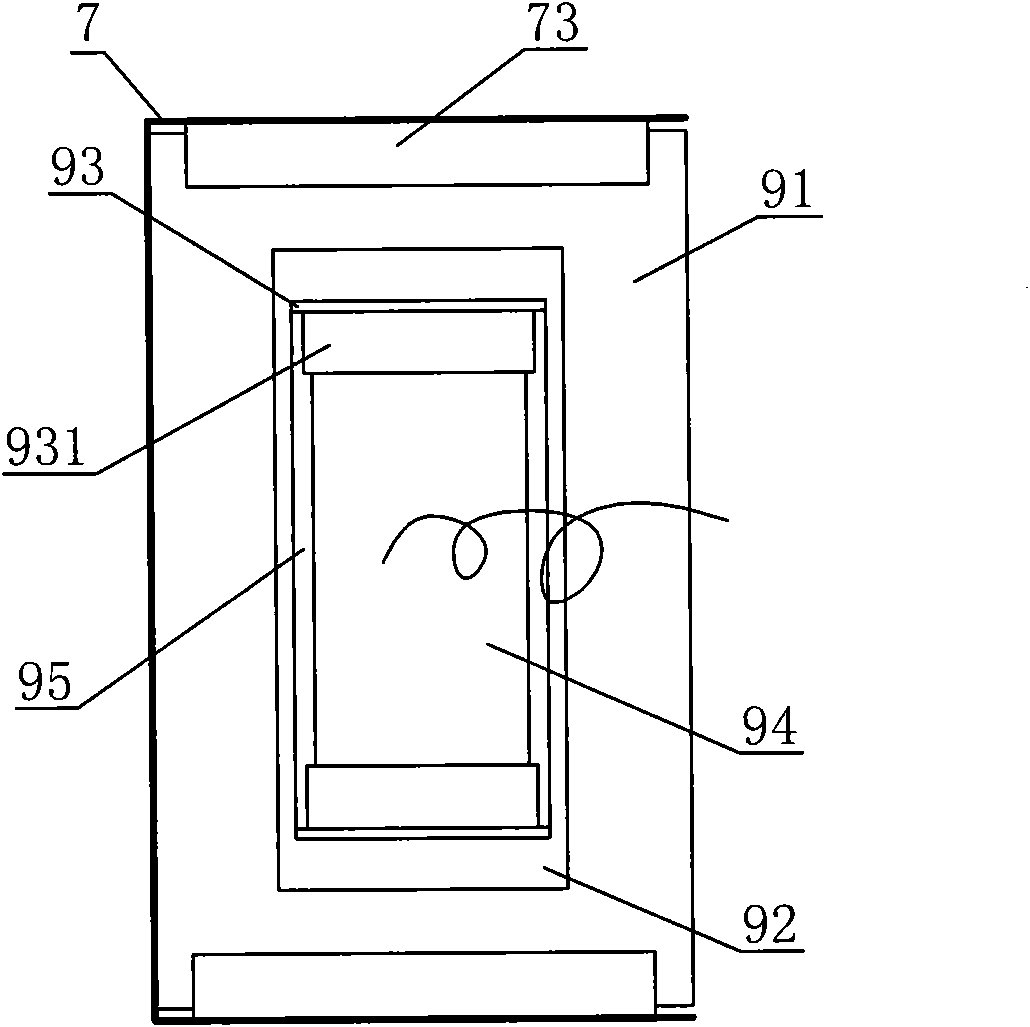

[0041] see Figure 1-Figure 3 Shown, a kind of electrolysis water machine, it is made up of source water purification treatment device 1, water mixing valve A 1 2. Solenoid valve B 1 3. Solenoid valve B 2 4. One-way valve 5, acidic water storage tank 6, electrolytic water tank 7, clean water storage tank 8, electrolytic component 9, water level sensor C 1 10. TDS sensor 11. Solenoid valve B 3 12. Water level sensor C 2 13. Solenoid valve B 4 14. Mixing valve A 2 15. Alkaline water storage tank 16. Water level sensor C 3 17. Water level sensor C 4 18. Water level sensor C 5 19 and water level sensor C 6 20 are connected to each other through pipelines and are connected with power supply and single-chip intelligent control device 21 through wires;

[0042] The source water purification treatment device 1 is connected with the water mixing valve A respectively 1 2 water inlet end, solenoid valve B 1 3. Solenoid valve B 2 4 is connected to the water inlet end of the o...

Embodiment 2

[0060] An electrolytic water generator, which differs from Embodiment 1 in that the purified water storage tank 8 is a water tank with heating / cooling functions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com